|

|||

|

|

|||

|

Page Title:

Section III. ORGANIZATIONAL MAINTENANCE TROUBLESHOOTING |

|

||

| ||||||||||

|

|

Section III. ORGANIZATIONAL MAINTENANCE TROUBLESHOOTING

troubleshooting malfunctions, probable causes and

4-6. General

recommended corrective actions. Probable causes and

For a general description and purpose of the

corrective actions beyond the scope of organizational

troubleshooting table, refer to paragraph 3-6.

maintenance shall be referred to direct support

maintenance.

4-7. Organizational Maintenance Troubleshooting

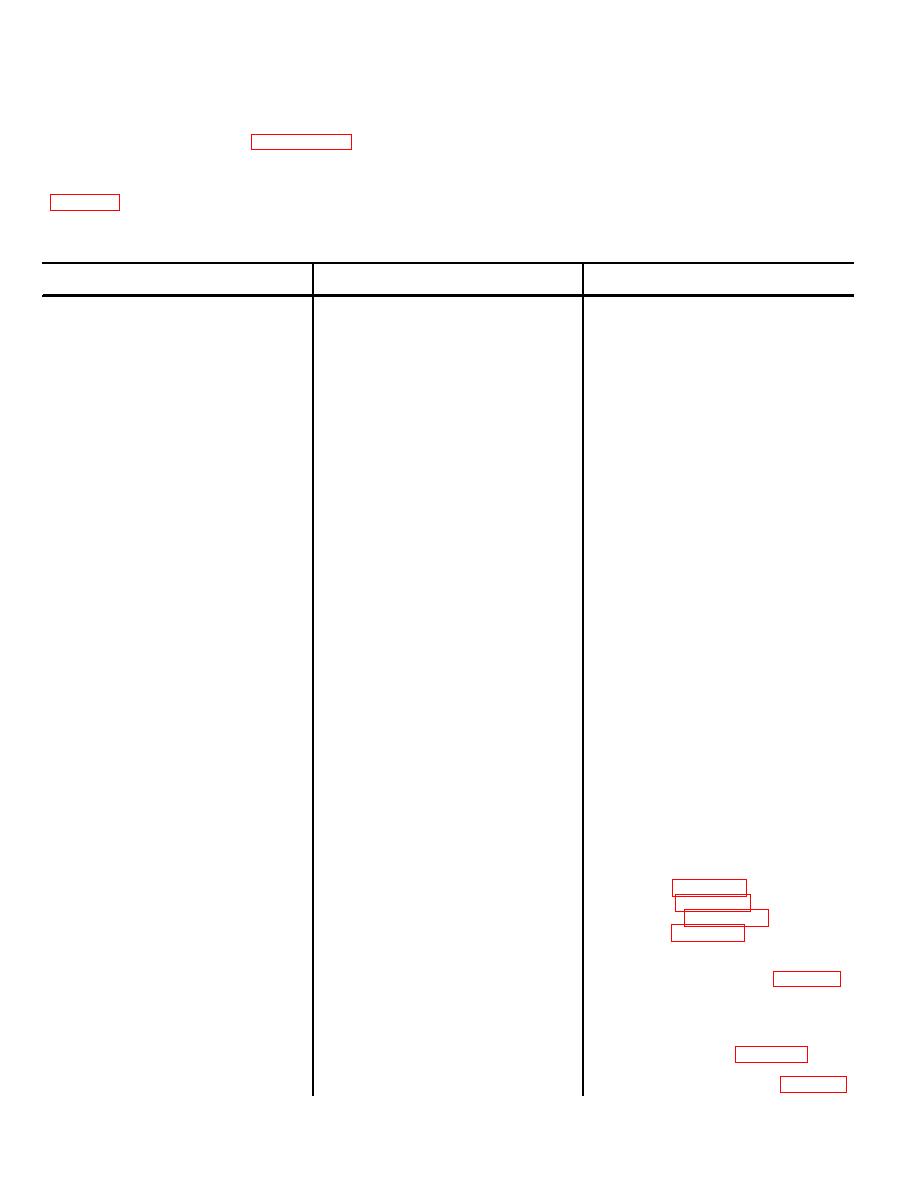

Table 4-2. Organizational Maintenance Troubleshooting.

Malfunction

Probable Cause

Corrective Action

1. Overheating (Breakers)

a. Contacts not aligned.

a. Refer to DS Maintenance

b. Contacts badly burned or pitted.

b. Refer to DS Maintenance

c. Contacts dirty, greasy or coated

c. Refer to DS Maintenance

with dark film.

d.

Refer to DS Maintenance

e. Current-carrying surfaces dirty.

e.

Refer to DS Maintenance

f. Current in excess of breaker rating.

f.

Refer to DS Maintenance

g. Corrosive atmosphere

g.

Refer to DS Maintenance

h. Insufficient bus or cable capacity.

h.

Refer to DS Maintenance

i. Bolts and nuts at terminal con-

i.

Refer to DS Maintenance

nections not tight.

j. Excessive ambient temperature.

j. Refer to DS Maintenance

2. Failure to trip AK-2 Breakers

a. Travel of tripping device does not

a. Refer to DS Maintenance

provide positive release of

tripping latch.

b. Worn or damaged trip unit parts.

b.

Refer to DS Maintenance

c. Binds in overcurrent trip device.

c.

Refer to DS Maintenance

d.

Refer to DS Maintenance

3. False Tripping AK-2 Breakers.

a. Overcurrent pick up too low.

a.

Refer to DS Maintenance

b. Overcurrent time setting too short.

b.

Refer to DS Maintenance

4. Failure to Close and Latch

a. Binding in attachments preventing

a.

Refer to DS Maintenance

(Breakers).

resetting of latch.

b. Latch out of adjustment.

b. Refer to DS Maintenance

c. Latch return spring too weak or

c. Refer to DS Maintenance

broken.

d. Hardened or gummy lubricant.

d. Refer to DS Maintenance

e. Safety pin left in push rod.

e. Refer to DS Maintenance

5. Burned Main Contacts

a. Improper contact sequence (main

a. Refer to DS Maintenance

contacts not sufficiently parted

when arcing contacts part.)

b. Short-circuit current level above

b. Refer to DS Maintenance

interrupting rating of breaker.

c. Loss of contact wipe or pressure.

c. Refer to DS Maintenance

6. Unnecessary tripping (Tripping

a. Set device for proper value ac-

when tripping should not occur.)

cording to ampere load of circuit.

b. Worm latch (breaker easily jarred

b. Refer to DS Maintenance

open ).

7.

Failure to close or latch.

Out of adjustment.

Refer to DS Maintenance

8.

Meters faulty.

Damaged meter.

Replace para 4-21

9.

Transformer gages faulty.

Damaged gages.

Replace. para 4-13, 4-14, 4-15

10.

Meter selector switch faulty.

Damaged contacts or Springs.

Replace. para 4-22

11.

Compartment heater not

Faulty heater.

Replace para 4-10, 4-20

working.

12.Trailer lights flicker or will not

a. Short circuit in trailer wiring or

a. Check wiring for breaks or bare

light

connection box

spots, tape bare spots. para 4-47.

b. Intervehicular cable damaged.

b. Replace cable.

c. Dirty or corroded contacts.

c. Clean contacts.

d. Other cause

d. Report other cause to DS

Maintenance.

13.Trailer brakes will not apply or

a. Adjustment too loose

hold

b. Clogged air filter

b. Clean air filter in service port of

emergency relay valve. para 4-42

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |