|

|||

|

|

|||

|

Page Title:

Section IV. RADIO INTERFERENCE SUPPRESSION |

|

||

| ||||||||||

|

|

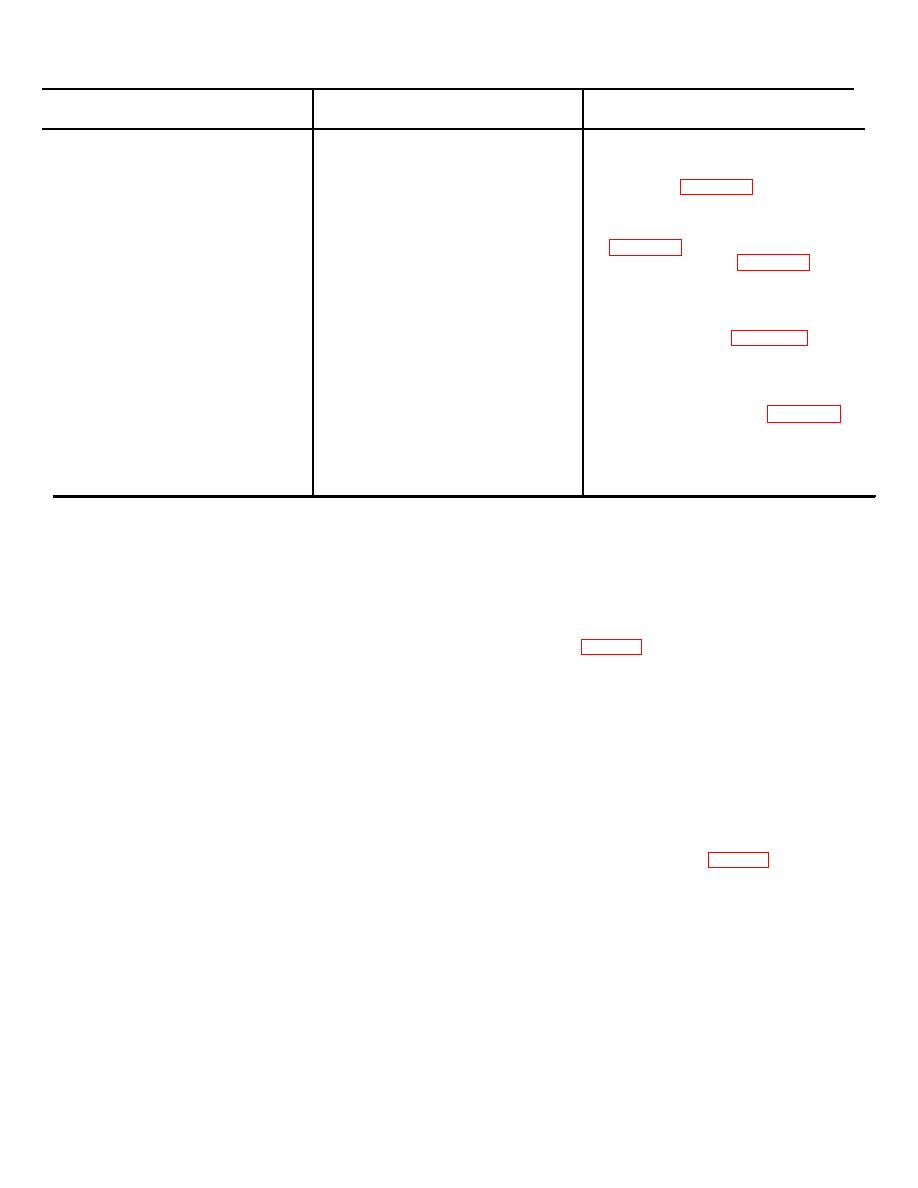

Table 4-2. Organizational Maintenance Troubleshooting Continued.

Malfunction

Probable Cause

Corrective Action

13. Trailer brakes will not apply or

c. Leaky intervehicular hose.

c. Tighten connections or replace.

Hold - Cont'

d

d. Test valve and replace if

necessary. para 4-42

e. Other causes.

e. Report other cause to DS

Maintenance.

14. Trailer brakes will not release.

a. Air hose connection wrong.

a. Check and make sure right hose

connections are made.

release.

c. Weak or broken brakeshoe

c. Refer to DS Maintenance.

retracting spring.

d. Other causes.

d. Refer to DS Maintenance.

15. Trailer brakes drag or grab.

a. Brakes adjusted too.

b. Weak or broken brakeshoe

b. Refer to DS Maintenance.

retracting spring.

c. Grease on brake lining.

c.

Refer to DS Maintenance.

d. Other causes.

d.

Refer to DS Maintenance.

16. Trailer wheels wobble and tire

a. Loose wheel bearing.

a.

Adjust wheel bearings. para 4- 39.

wear uneven.

b. Broken wheel bearing.

b.

Replace wheel bearings.

c. Bent wheel.

c.

Replace wheel.

d. Other cause.

d.

Refer to DS Maintenance.

17. Trailer will not track when

Bent, misaligned axle, broken spring.

Refer to DS Maintenance

towed.

Section IV. RADIO INTERFERENCE SUPPRESSION

as its source of power. The unit is grounded and the

4-8. General

enclosures are shielded.

The substation is a static or passive device which will

not generate any EMI. Its transmission is only as good

Section V. MAINTENANCE OF HIGH VOLTAGE INCOMING SECTION

4-10. Heater (fig. 2-3).

4-9. Enclosure

Replacement of high voltage cabinet heater.

Keep hinges for front panels tight, free from bends that

(a use binding and pivot pins straight. The pins are not

the removable type and the panel side of hinge is

a. Loosen screw on heater end and remove two

welded to the panel. If the hinge is beyond repair the

wires.

panel assembly must be replaced. The assembly is

b. Loosen bolts of retaining clips.

bolted to cabinet with two lock nuts on each hinge. By

removing these four lock nuts the panel assembly may

c. Remove heater.

be removed and a new one installed.

d. Install new heater in reverse order.

Section VI. MAINTENANCE OF TRANSFORMER

4-11. General

4-12. Vent Valve Replacement (fig. 3-9)

The insulating liquid must be maintained at the proper

The vent valve has a square body with knurled control

level 4see name plate) and the dielectric strength of the

knob at one end. The other end has a NPT valve. With

liquid should be maintained at a high value. The liquid

transformer de-energized an vented to the atmosphere,

should be sampled and tested after the first few days of

unscrew the vent valve from the transformer. Apply

operation, again after six months, and yearly thereafter.

teflon tape or pip compound to the threads of new vent

Keep accurate records of the test and filter or replace

valve. If replacing a used valve make sure threads

the liquid as indicated.

The sampling and test

have bee thoroughly cleaned. Insert valve replacement

procedures are in TM 5-6120-250-34.

an screw in until tight.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |