|

|||

|

|

|||

|

Page Title:

Section V. WIRING HARNESS AND CABLE REPAIR |

|

||

| ||||||||||

|

|

TM

9-2350-238-20-2

Section V. WIRING HARNESS AND CABLE REPAIR

2-11.

G E N E R A L . This section contains instructions on repair of wiring harnesses and cables

(leads). Repair of wiring harnesses and cables consists of replacement of defective connectors,

shells and terminals or taping cut or worn insulation and exposed wire conductors. Pages 2-66

thru 2-72 show exploded views of typical harness and cable connectors used on the vehicle,

and give procedures for disassembly and assembly

of

connectors.

When

is

required,

procedures in TB SIG 222 must be followed.

NOTE

Label

cables

on

multiple

during

disassembly

to

insure

proper

order

during

reassembly.

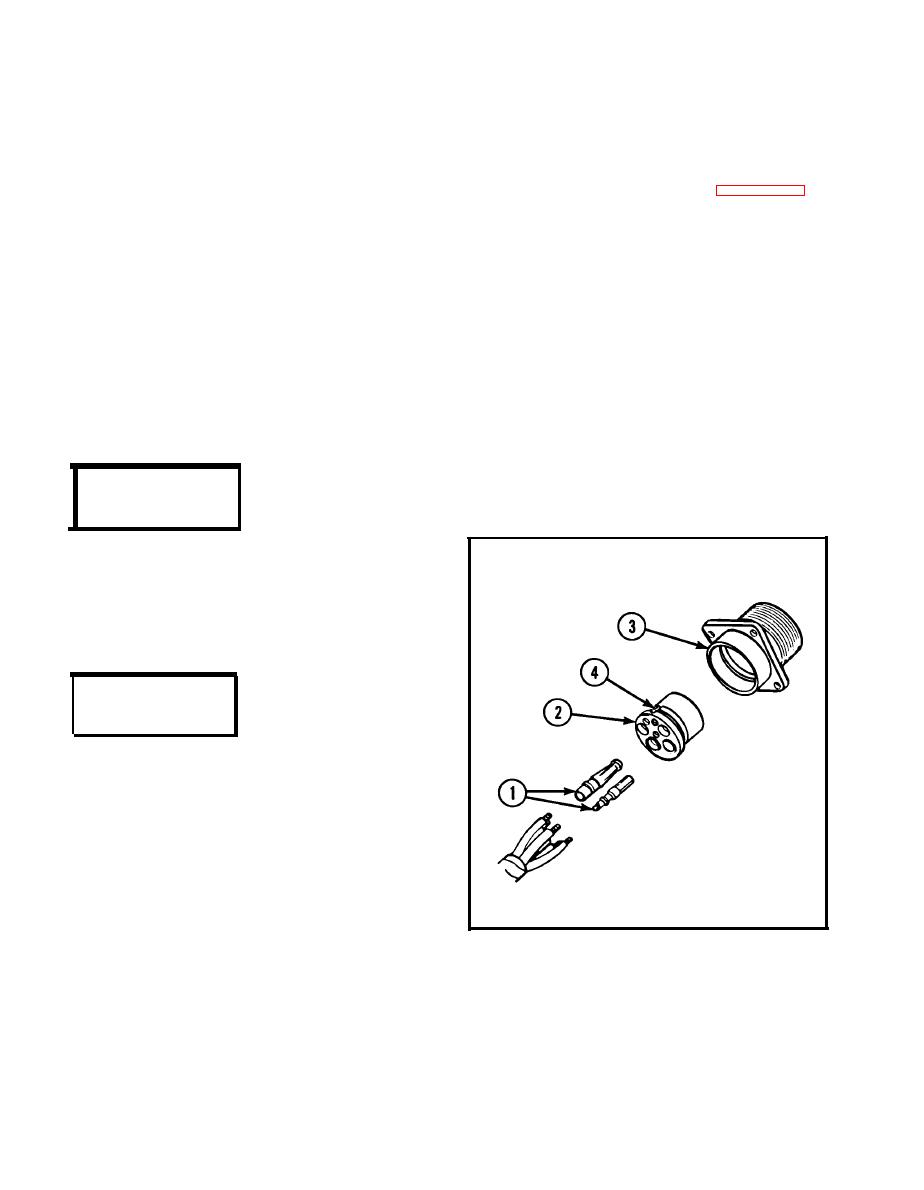

2-12. TYPICAL FEMALE-TYPE

PANEL

MOUNTING RECEPTACLE.

DISASSEMBLY

1 Drive socket contacts (1) out through

rear of insert (2) with pin extractor.

2 Unsolder

cable

leads

from

solder

wells

on

socket

contacts

(1).

3 Slide insert out through rear of shell

assembly (3).

REASSEMBLY

1

Strip cable insulation equal to depth of

solder

wells

of

socket

contacts

(1).

2

Insert cable leads into solder wells of

socket

contacts

(1)

and

Push insert (2) into shell assembly (3)

3

from rear until seated. Groove (4) in in-

sert must be alined with guide in shell

assembly (3) to ensure proper fit.

4

Push socket contacts (1) into insert (2)

from rear until seated.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |