|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1300-275/3

b. Appropriate decontaminant.

c. The toxic agent patching kit.

d. A wrecking bar for dismantling dunnage.

3-2 M494 CONTAINER.

2-2.1 Identification of M494 Container.

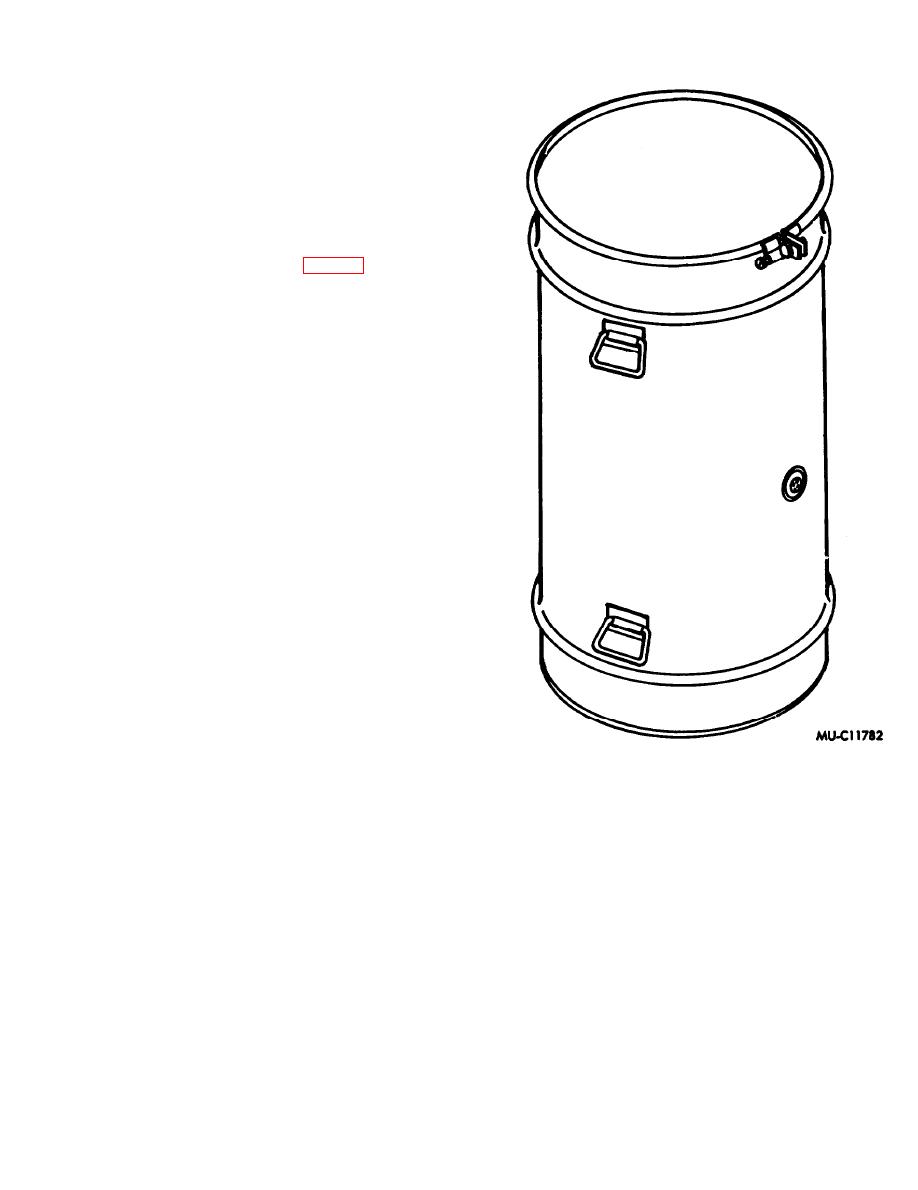

The M494 container resembles a 55-gallon steel

drum. It is 37 inches high and 24 inches in di-

ameter. Four spring-loaded, retractable handles

are welded to the drum (fig. 3-6). A venting port

is installed on one side of the container. An hu-

midity indicator is installed on the opposite side.

The lid is fastened to the drum by a locking ring

held in place and tightened by two locking-ring

bolts.

2-2.2 Hazards

Agent leaks' from defective seams, venting port,

humidity indicator, or handles.

2-2.3 Principles of Operation.

3-2.3.1 Testing. To assure that an M494 con-

tainer will not leak, check it (unless checked pre-

viously) during the 3-month period before a mis-

sion and immediately after a mission.

3-2.3.2 Examine the container for:

a Dents on lid or locking ring.

b. Dents on bottom edge.

c. Welds that have burned through the body

of the drum.

d. Loose port or humidity indicator.

3-2.3.3 If any of the foregoing defects are noted,

repair the defect, if possible. If defect cannot be

repaired, discard the item.

3-2.3.4 Using a 1/8-27 NPT tap and suitable

lubricant, cut threads on the inside of the vent

ing port. Avoid turning the tap too far in and

making the resultant, tapered, female threads

too large for the male threads on the tank valve.

Figure 3-6. M494 Container.

Correctly cut threads will not allow the shoulder

of the tank valve to touch the venting port.

of more than 10F. will invalidate the test.

3-2.3.5 At least once each year, replace the gas-

3-2.3.9 Containers passing this test should be

ket for the drum cover. Do not use any cement

so marked, including the date of the test. Loosen

when installing a new gasket.

the locking ring bolt all the way. Install another

3-2.3.6 For testing, insert one bolt with a flat

bolt, with flat washer, in the upper holes of the

washer under its nut into the lower hole of the

locking ring.

locking ring, and install the cover.

2-2.4 Use.

3-2.3.7 Pressurize the container at 5 psig., and

Assure that all items placed in these containers

dip various areas in water to check for leaks. Pay

are packed to prevent movement inside the con-

special attention to the lid gasket, the handles,

tainers. Sand, dirt, or other filler may be used.

port, humidity indicator, and bottom seam.

Install the container lid and tighten the locking-

3-2.3.8 If no leaks are detected, store the con-

ring bolts. Turn one bolt until slight resistance is

tainers and recheck the pressure 1 week later. If

felt; then tighten the other, alternating until both

the pressure drops more than one-half psig.,

bolts are snug. Check the locking-ring area for

reject the container. Check the temperature both

agent leakage.

times the container is pressurized. A variation

21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |