|

|||

|

|

|||

|

Page Title:

Section IV. INSTALLATION AND CIRCUIT LINEUP |

|

||

| ||||||||||

|

|

leads and number 22 wire (MIL W-76), or equivalent, for the tamper loop and the case ground (as shown on figure FO-1

located at rear of manual) run the cable through the conduit between each enclosure and allow a generous service loop

at each enclosure to facilitate cable preparation and connection to the respective terminal boards

c. Lead Preparation. Prepare the cable lead ends and fasten a crimp lug to each lead. Attach a connecting lead

and crimp lug to the shield of each coaxial lead.

d. Reinstall Unit Circuitry. Fasten the respective pc board to the processor and detector enclosures using the

reserve order of procedure in paragraphs 2-10a and 10b.

e. Lead Connections. Connect the cable leads to the processor and the detector screw type terminal strips in

accordance with the configuration used, as shown in interconnection data in figure FO 1 (located at rear of manual).

NOTE

For detectors served by a angle prior, all the detector signals are parallel connected in fine

circuit and all the tamper switches in both the processor and the-detectors on all connected in

series.

Section IV. INSTALLATION AND CIRCUIT LINEUP

2-13. General

To maximize detection capability, the processor SENSITIVITY control must be set to accommodate the location requiring

the greatest sensitivity. The data recorded in the preliminary adjustments (para 2-8d)(3) for the processor SENSITIVITY

control setting is used for the final setting.

2-14. Equipment Test and Final Adjustment

The equipment is now ready to be checked for tamper switch circuit continuity, and the final adjustment made of each

detector GAIN setting.

a.

Tamper Circuit Test. This test involves the use of two men, one

to monitor the continuity indicator and the second to move from unit to unit to remove enclosure covers and verify the

tamper switch operation and check the switch plunger travel.

(1) Remove the cover (fig. C-3) from the processor and pull the tamper switch (fig. 1-1) plunger out to

complete the circuit in this enclosure.

(2) Temporarily remove the lead from terminal 5 of TB1 (fig. 1-1) that goes to the J-SIIDS control unit.

(3) Connect a multimeter (AN/USM-210 between terminals 2 and 5 of TB1 (fig. 1-1). With the covers secured

to all the detector enclosures and the tamper plunger of the processor pulled out, the continuity should be approximately

that indicated in table 2-2 for the wire size used and the approximate cable run distance.

NOTE

The approximate resistance per 1000 feet for various wire sizes is given in table 2-2.

Double the approximate wire non distance to each unit to account for completing the

tamper loop.

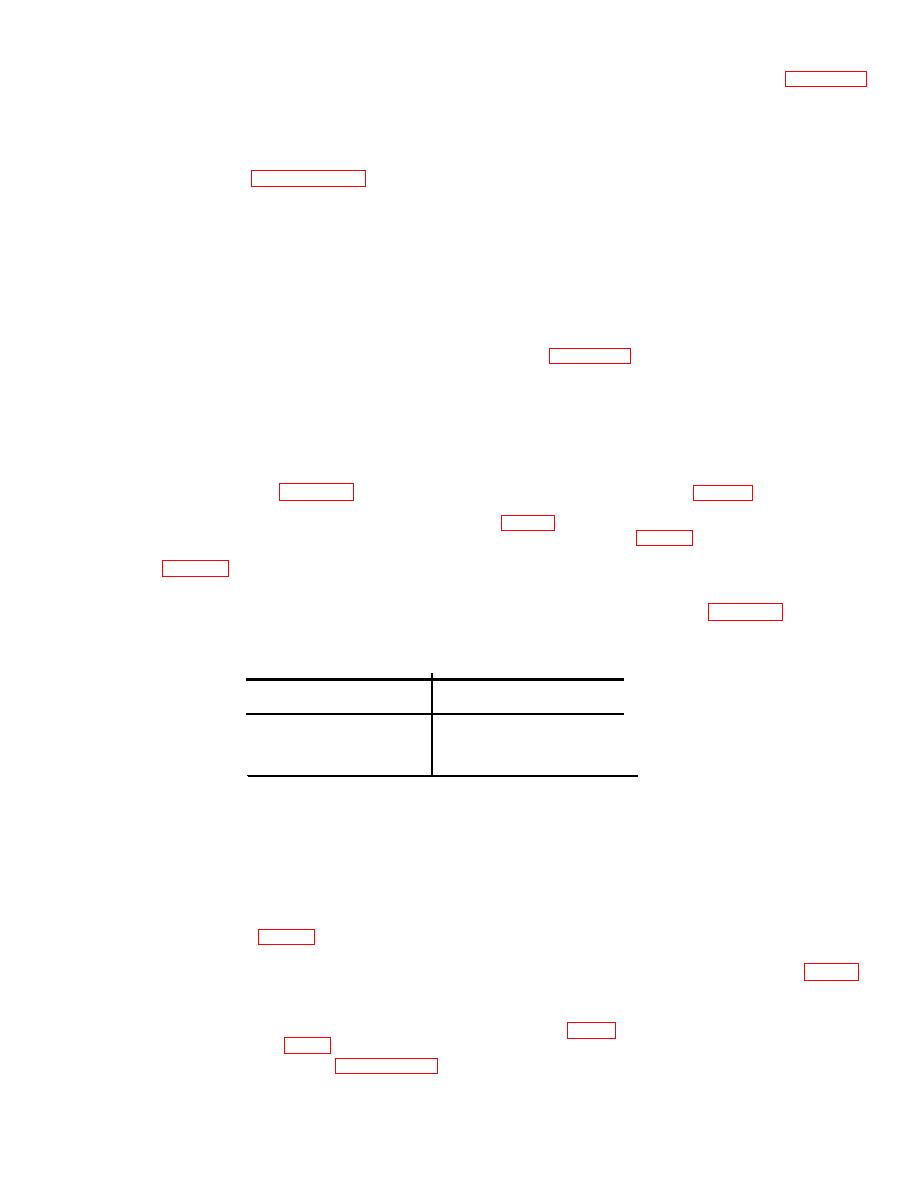

Table 2-2. Wire Resistance Per 1000 Feet

Wire

Ohms per

size

1000 feet

16

4.1

18

6.6

20

10.36

*22

16.46

*Suggested wire size (MIL-W-76)

(4) Remove the enclosure cover of each unit (one at a time) and verify that the continuity goes to infinity (open

circuit) The switch should open with no less than 1/8 inch nor more than 1/4 inch of cover displacement. If the switch

fails to meet these requirements report malfunction to direct support Intermediate) maintenance. Pull the tamper switch

plunger out and verify that the continuity is complete and the resistance approximates that of the established tamper

circuit. Fasten the cover to the enclosure and again verify that the continuity is complete and the resistance

approximates that of the tamper circuit.

(5) Repeat steps (4) above for each of the enclosures.

(6) To simulate the cover on the processor enclosure use a straight edge across opposite sides of the enclosure

to depress the tamper switch (fig. 1-1) plunger. The switch plunger should meet the same requirements as outlined in

step (4) above. Verify that the continuity is complete and the resistance approximates that of the tamper circuit.

(7) Remove the multimeter test leads and reconnect the temporarily removed lead to terminal 5 of TB1 (fig. 1-1)

b. Processor/Detector Vibration Signal Adjustment. Adjustments and checkout of the processor/detector vibration

signal is performed as follows:

(1) Connect the multimeter (AN/USM-210) positive lead to the MV (fig.1-1) test point and the negative lead to

signal ground (terminal 8 of TB1, (fig.1-1). Set the multimeter to read D.C and the selector switch to 50 V.

(2) Perform the applicable steps in paragraph 2-8d(3) to check out the processor/detector vibration signal.

2-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |