|

|||

|

|

|||

|

Page Title:

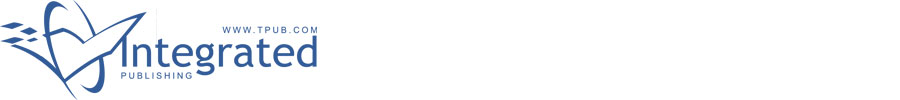

Figure 8-20. Installing special gasket |

|

||

| ||||||||||

|

|

TM 5-5430-209-12

1. LAST BOTTOM SECTION

2. POINT OF INSTALLATION OF SPECIAL GASKET

3. NEXT-TO-LAST BOTTOM SECTION

ME 5430-209-12/8-20

Figure 8-20. Installing special gasket.

(b) Measure the actual length of this gap and

cut two pieces of strip gasket (2, fig. 8 13) to match this

length.

(c) Bevel each end of the gaskets. This will

make them seal tight against each other and against the

seam of the section.

(d) Remove the finger-tightened nuts along

the seam in the area of the gap.

(e) Block up the freed area of the seam with

a short length of 2-by 4-inch lumber, clear of the gap.

(f) Force a strip gasket over the bolts. Apply

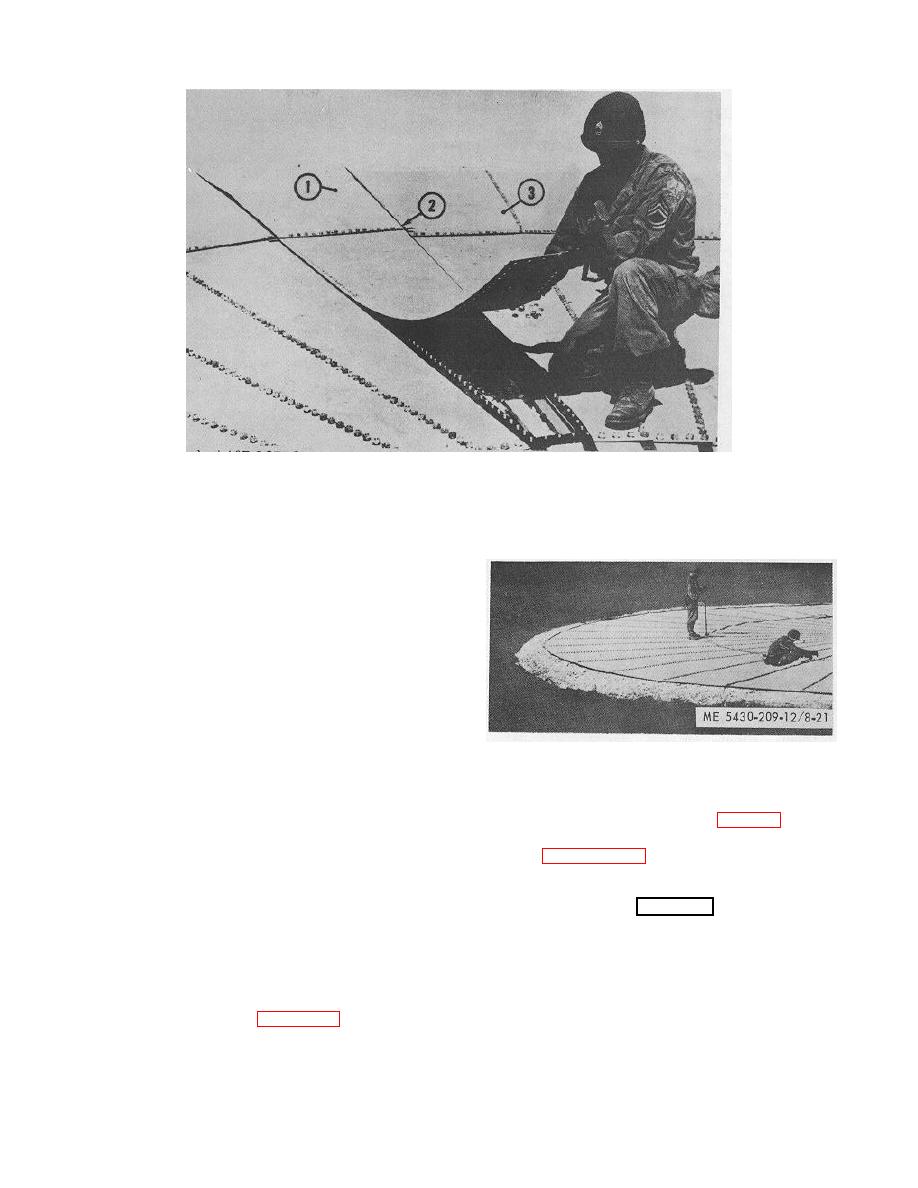

Figure 8-21. Tightening bolts in tank bottom.

a heavy coating of sealing compound along the top face

8-6. Bolt Replacement Plug

and under each end of the gasket.

If threads are stripped on one or more bolts in the tank

(g) Force the remaining strip gasket over the

bottom during tightening process, drive out the bolts and

top of the first gasket.

replace it with a replacement plug (para 3-4).

(h) Remove the blocking so the section will

8-7. Testing Seams for Leakage

drop back to its original position.

Refer to paragraph 3-5 and test tank bottom seams for

leakage.

8-5. Tightening Tank Bottom

8-8. Sealing Seams

a. Work from small end of the sections and remove

WARNING

all finger-tightened nuts.

If tank is to be used for water storage, do

b. Install steel recessed washer, cup side down, and

not apply sealing compound to tank bottom.

nut on each bolt in the tank bottom except those in the

Sweep clean the tank bottom. With bottom dry, apply

outer circumference (chime) which secure the first stave

sealing compound to all bolts and seams.

rings.

c. Tighten all nuts in the tank bottom starting at the

small end of the sections. See figure 8-21.

8-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |