|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

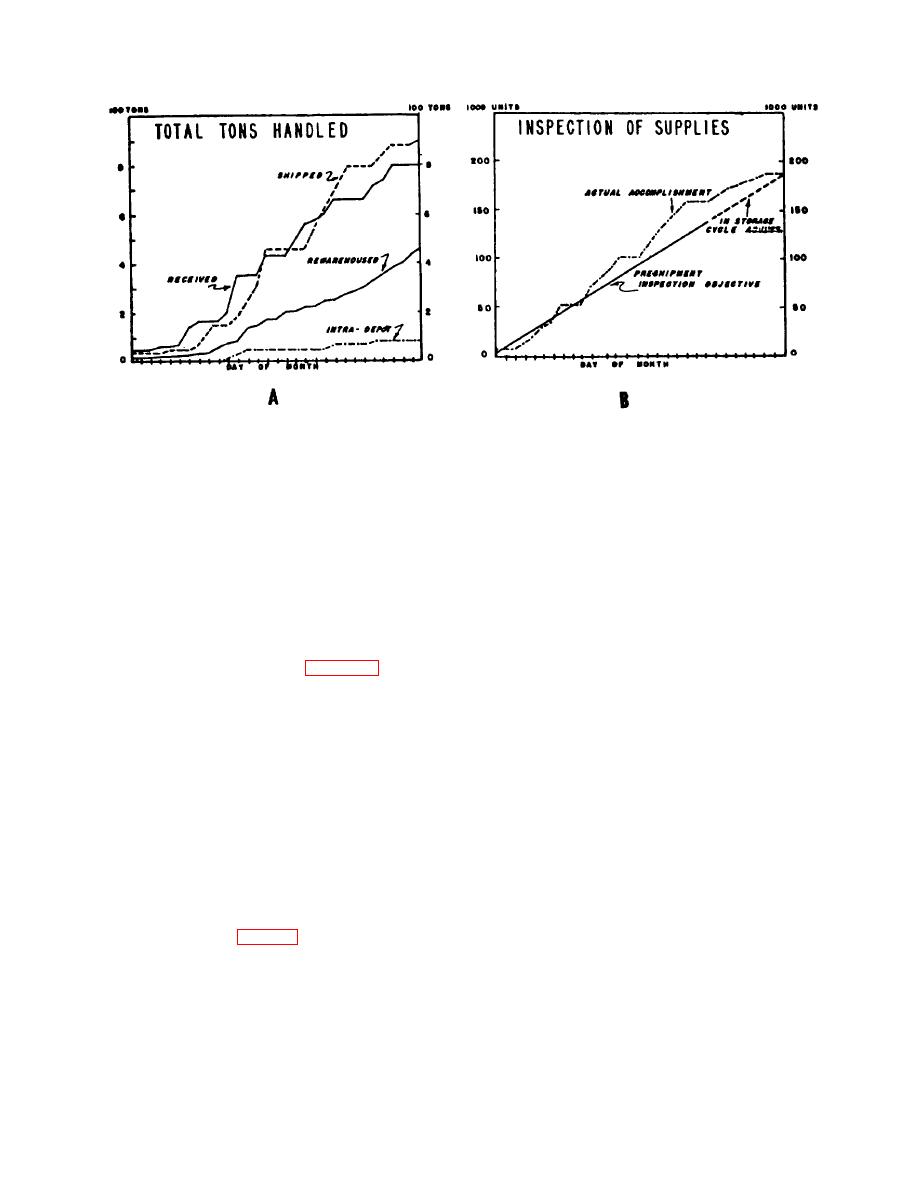

Figure 8-1. This type of chart shows where you have been, where you are, and where you are heading.

deficiencies may be entering the operation. Some of

(1) Productivity to date as better or worse and

these may be crosshauling that could be reduced or

its plus or minus relationship to the record of the

eliminated, the use of inefficient or improper vehicular

previous day or week.

equipment, or lack or proper planning or supervision.

(2) Current productivity comparison with that

Generally speaking, the less the intra-installation

of the previous month or year.

material movement and handling and the more the

tonnage handled in and out, the healthier the situation.

e. Charts may be kept on a daily, weekly, or

k. Figure 82B shows the material inspection

monthly basis according to type data presented.

(quality control) objective(s) for a given period. In the

f. In preparing charts, the first step is identification

example, the number of units anticipated for

and insertion of the acceptable performance standard.

preshipment inspection is shown together with an

g. Next, apply horizontal lines above and below

estimate of in-storage or in-process inspections planned

the identified standard. As shown in figure 8-1 (A and

or scheduled which, in the main, would have negated

B), one line is drawn at 20 percent above the standard

the need for preshipment inspection. The dotted line

and another drawn 20 percent below standard.

shows how close to attainment of the objective was the

h. An activity is rarely able to judge its progress

accomplishment.

overall by how many units are processed on a given day

but rather by how many units were processed through a

8-5. Analysis of Methods.

given date in a period of time. An acceptable means of

accomplishing this is if, beginning with the first day of

a. Analysis to precede equipment selection. MHE and

the month, the performance units per production man-

tools should not be selected or requisitioned for an

hour are inserted for that day. On the second day, the

operation until after a thorough analysis has been made

first and second day's performance is added. Average

of the materials to be handled, the conditions and

the two and insert the figure, and so on.

environment in which the work will be performed, and

the method to be employed.

i. Charts should be large enough to be easily read

and placed in a conspicuous location to command

b. Operation lists. In any handling problem, there will

attention to personnel employed in the activity.

be several specific operations which must be performed.

Listing these operations, in the sequence performed,

activity is normally the sum of tons received and tons

may be sufficient to indicate

shipped. A rise in handling intra-installation tonnage or

a continual and significant increase in intra-installation

tonnage bears investigation because a number of

8-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |