|

|||

|

|

|||

|

Page Title:

Section VI. Care of Supplies in Storage (COSIS) |

|

||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

since the last inventory that would explain the

means. When this happens, and the storage cannot be

discrepancy and preclude report of survey actions.

explained by offsetting adjustments, erroneous posting,

m. When an approving authority is examining

or improper shipments, they will direct preparation of DD

inventory adjustment reports prior to approval, they may

Form 200 (Report of Survey). This form will be

decide through personal judgment and experience that

prepared by the responsible officer and processed in

an item shortage may be due to loss through pilferage,

accordance with applicable service agency regulations.

theft, or other unauthorized

DD Form 200 is not used by Army users.

Section VI. Care of Supplies in Storage (COSIS)

3-38. General.

feedback information will be used to supplement the

Caring for supplies to assure a ready-for-issue condition

regular cyclic inspection to evaluate the adequacy of the

is an important task. The DOD Components prepare

COSIS program.

and publish detailed instructions to provide for the care

of items for which they have management responsibility.

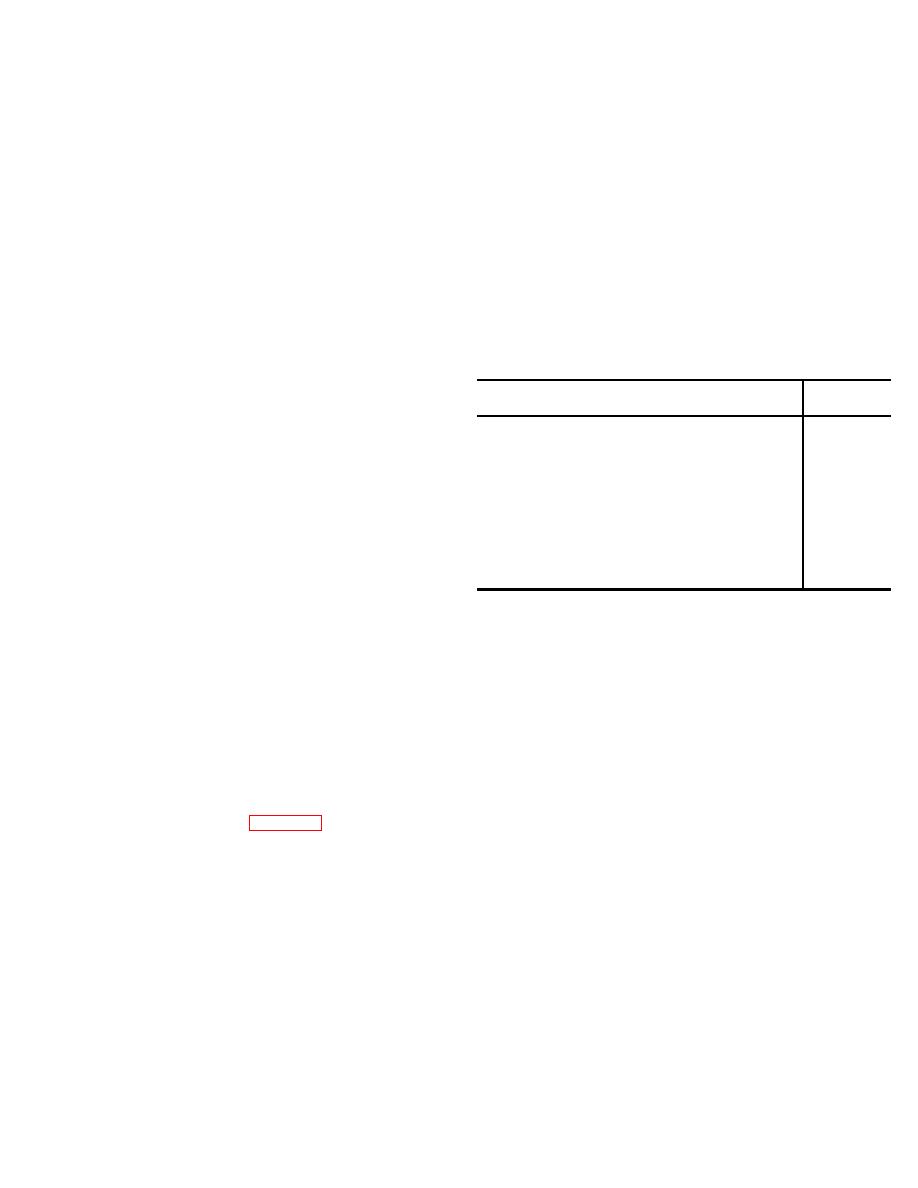

Table 3-3. Inspection Frequencies for Material not

Such publications will agree with the policies of this

Covered by Storage Serviceability Standards

manual. The use of quality control techniques and

Type of Storage

storage serviceability standards will enable a COSIS

(Months)

program to be accomplished at minimum cost with

CH (or equivalent rating when such rating has

optimum efficiency. Quality control and deterioration

been approved by higher authority ..........

60

data will be generated to be used for improving

standards of serviceability, specifications, and

Controlled temperature warehouse ............

30

procurement quality standards.

Noncontrolled temperature warehouse .......

24

3-39. Policy.

a. A program for COSIS must include a quality

Shed/transitory shelter ..............................

12

control system for inspection and/or test, a system for

reporting and recording quality control data, provisions

Open .........................................................

6

for the entry of true condition code of material into item

balance records, exercising applicable material, and a

3-40. Objectives.

system to assure corrective actions are accomplished

The objectives of a COSTS program are to

on material deficiencies uncovered by inspections.

a. Maintain material readiness posture in CONUS

DOD Components will determine the degree of activity

and overseas commands at an optimum level.

required in each phase of the program and establish

b. Assure that the true condition of material is

procedures. Major factors affecting the degree of

known and recorded through cyclic inspections and

activity are the type of item, type of storage provided,

tests.

and anticipated length of storage.

c. Provide a basis for realistic workload forecasts

b. For material not covered by storage

to determine and substantiate budget and manpower

serviceability standards or other adequate inspection

requirements.

procedures, frequency of material inspection (excluding

d. Assure that only material representing current or

shelf-life items) will be based on the type of storage

anticipated supply system requirements is scheduled

provided for the material (table 3-3). Frequency of

for

preservation/represervation

and packing to

inspection for shelf-life items will be based on expiration

preclude expenditure of resources on excess or obsolete

dates.

material.

c. Adequate protection from the elements and

e. Permit adjustments in storage inspection

environmental conditions will be provided by means of

frequencies and quality control efforts to provide greater

proper storage facilities, preservation, packing, or a

efficiency and economy through analysis of data

combination of these measures.

concerning variation in deterioration rates.

d. The results of quality data generated from

analysis of inspection of items during shipping, set

3-41. Responsibilities.

assembly, special inspections directed by the item

a. The care of supplies is an integral part of the

manager, customer complaints, and other quality

storage and quality control responsibilities.

To

discharge these responsibilities properly and with a

minimum of cost, a carefully developed program is

necessary at all echelons.

3-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |