|

|||

|

|

|||

|

Page Title:

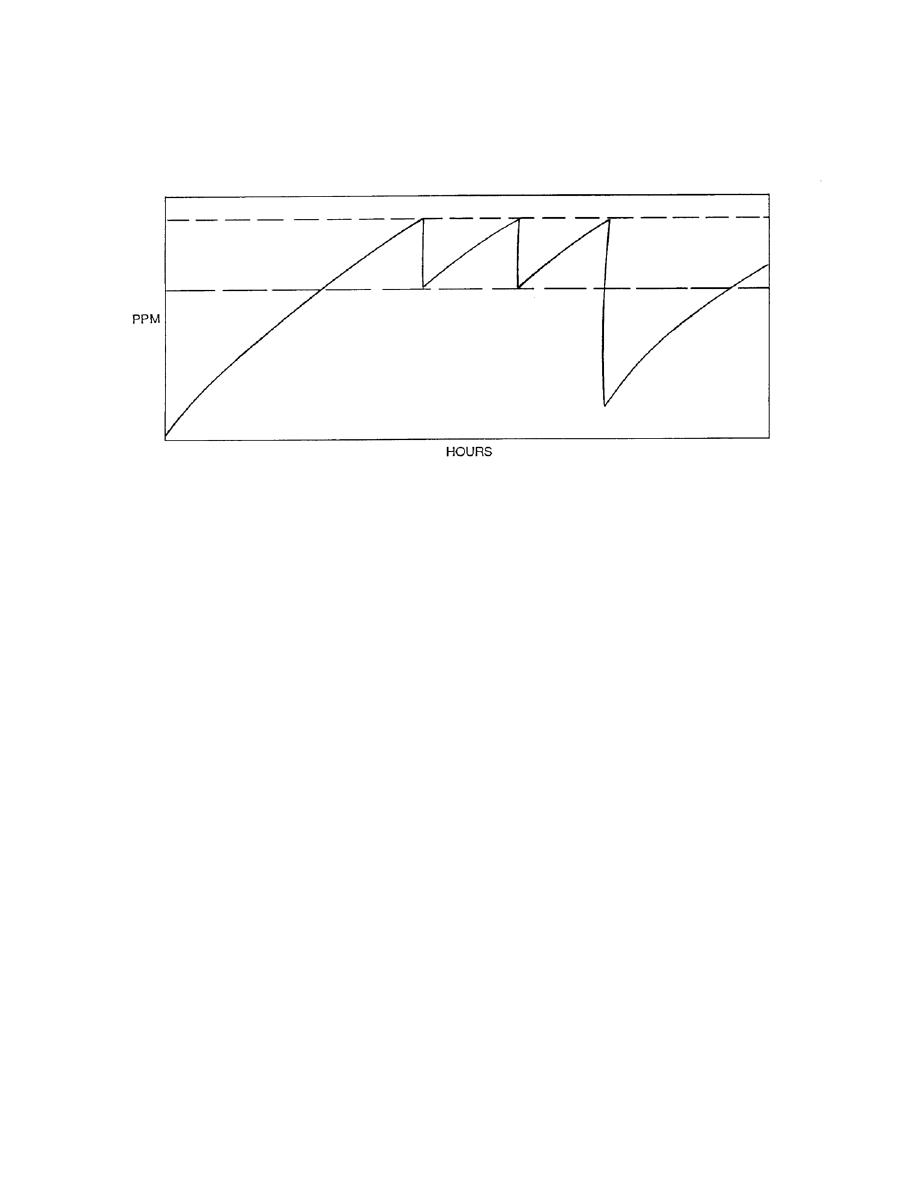

Figure 2-3. Effect of Periodic Fluid Addition and Fluid Change |

|

||

| ||||||||||

|

|

NAVAIR 17-15-50.1

TM 38-301-1

T.O. 33-1-37-1

CGTO 33-1-37-1

k. Evaluation Information. Time since new or overhaul must be reported correctly, and the evaluator must

remain alert to detect any inconsistencies in these data. When necessary, the customer must be contacted to

check on the validity of any suspect values that affect the evaluation. The reporting of an incorrect time for the

component may cause the evaluation to request a component removal rather than an oil change or reducing the

sampling interval. It is also important that information on component maintenance be reported and considered in

the evaluation process.

l. Filter/Screen Checks. Information regarding the examination of filters or screens during routine

equipment servicing can often augment spectrometric analysis. Large particles accumulated on filter screens

may or may not be accompanied by high spectrometric wear-metal indications. Normally, the wearmetals

detected and measured by spectrometric analysis are too small to be trapped on a filter screen. Therefore, visible

particles on the screen and high wear-metal content (spectrometric) may be detected independently. When large

metal particles are detected in the oil system, either on filters or chip detectors, the source of the metal should be

determined, if possible, or the equipment should be placed on shorter chip detector/filter inspection and/or oil

sampling intervals.

m. Operating Conditions. The mission profile concerns the load factor and manner in which the equipment

is operated. Generally speaking, equipment that operates at high percentages of maximum load at all times, will

show a higher concentration of wearmetals. Extreme operating load factors invite engine and power train

problems. Under normal loads and less demanding conditions, most equipment operates at lower, more stable

wear-metal concentration levels. Equipment operated intermittently may exhibit symptoms associated with

corrosion.

n. Feedback. Operating activity feedback containing maintenance or operating information that may affect

the oil analysis results must be included in the evaluation process. For example, a sudden increase in

wearmetals may indicate a severe wear condition, but may also indicate that maintenance was performed on the

component since the last sample was taken. Overboosts, overspeeds, overtemps, cylinder or rings replaced,

overtorque, vibration, corrosion found, repair or adjustments on components, color of oil, mission profile

information, compressor stalls, unusual noises from the component and filter/screen and chip detector

inspections are all bits

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |