|

|||

|

|

|||

|

Page Title:

CHAPTER 2 DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 9-1240-311-34

CHAPTER 2

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE

INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

2-1.

Special Tools and Equipment

2-2.

Direct

Support

and

General

Support

Special tools and equipment necessary to perform

Maintenance

operations described in this manual are listed in table 2-

Repair Parts Repair parts are listed and illustrated in TM

9-1240311-34P.

Maintenance instructions contained

TA and TOE.

herein pertain only to replacement of repair parts

authorized at the direct support and general support

maintenance levels.

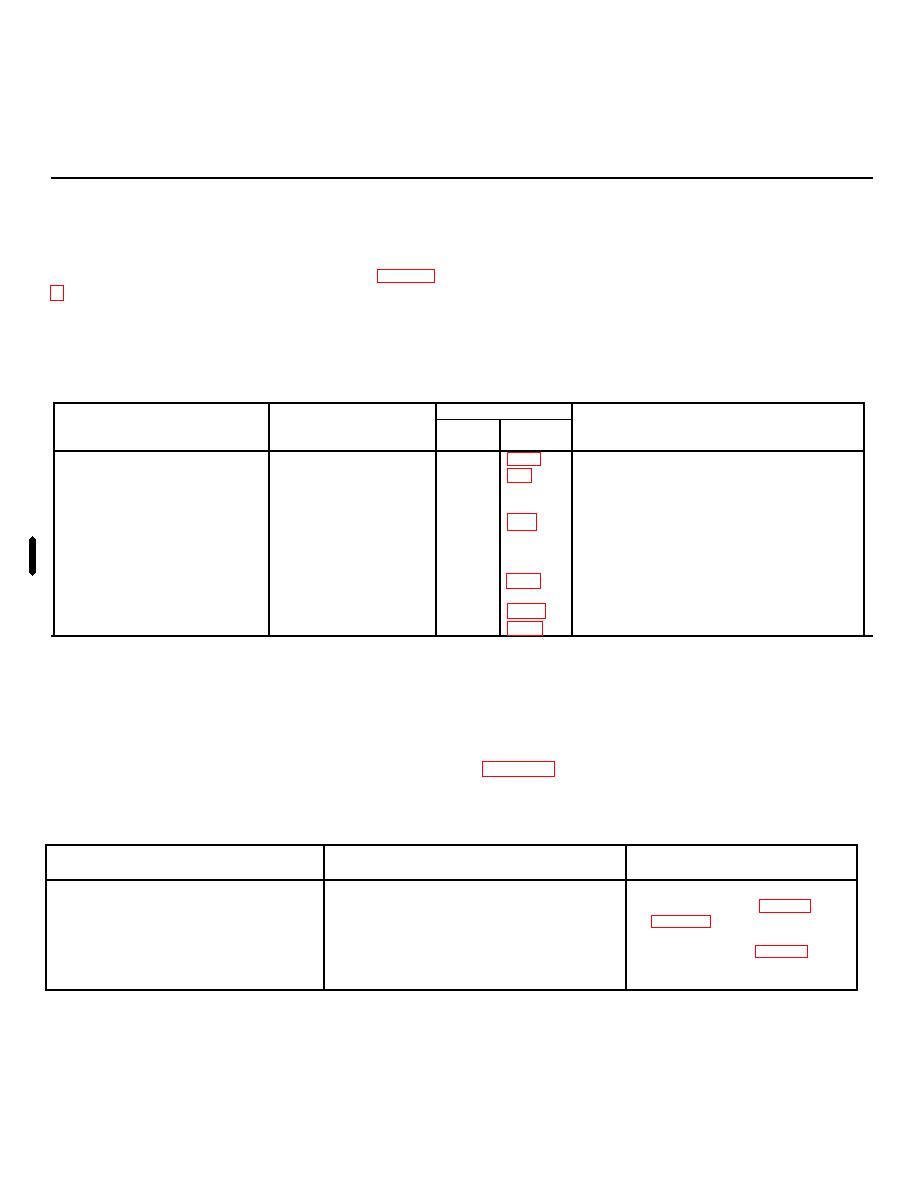

Table 2-1. Special Tools and Equipment

Reference

Item

FSN or

Fig.

Para.

Use

Part No.

No.

No.s

Adapter, Sealing 8-32 UNC-2

4930-107-4378

Used with gun, sealing 4931-764-8134

Dioptometer

4931-536-5557

To make optical checks when removing

parallax and adjusting for sharp eyepiece

focus.

Gun Sealing Hydraulic

4931-764-8134

Used with adapter 4930-107-4378 to inject

sealing compound.

Wrench, Spanner, Adjustable,

5120-595-8996

Used to remove and replace screws 8590832

Pin Type

and 8624629, retainer 10533426, and studs

8624623 and 8624624.

Section II. TROUBLESHOOTING

Troubleshooting performed by lower levels

of

2-3.

General

maintenance are listed in TM 9-2350-230-12.

Troubleshooting is a systematic means of determining by

symptoms, malfunctions within the instrument.

2-4.

Procedure

Adherence to procedures covered herein will materially

reduce the time required to locate trouble and restore the

instrument to normal operation.

and general support maintenance levels.

Table 2-2. Troubleshooting

Malfunction

Probable Cause

Corrective Action

a. Replace spring (9, fig. 3-2).

Headrest is not held in secured position

a. Plunger not securing headrest.

when placed in bracket.

b. Check support (4, fig. 3-2),

b. Support on headrest not alined with plunger.

straight en if bent

Change 1 2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |