|

|||

|

|

|||

|

Page Title:

MAINTENANCE OF DRIVE HUB SPROCKETS AND RELATED PARTS. |

|

||

| ||||||||||

|

|

TM 9-2350-238-20-1

2-150. MAINTENANCE OF DRIVE HUB SPROCKETS AND RELATED PARTS.

b. Inspection/Repair

c. Installation

This task covers: a. R e m o v a l

INITIAL SETUP

Materials/Parts

Tools and Special Tools

Dry cleaning solvent (item 16, appx C)

Automotive maintenance and repair shop

Emery cloth (item 11, appx C)

equipment: organizational maintenance,

Hydraulic fluid (item 21, appx C)

common no. 1 (less power) (item 80,

Lockwasher (22)

Olive drab enamel (item 18, appx C)

q Breaker bar (3/4-in. drive)

Primer (item 31, appx C)

q Socket (1-1/2-in., 3/4-in. drive)

q Torque wrench (0 to 170 ft-lb)

Personnel Required

q Torque wrench 0 to 600 ft-lb)

Two

q Wire brush

Hoist

References

Hub and sprocket lifting sling (item 25,

TM 9-2350-238-24P-1

Sprocket wear gage (item 7, appx G)

Equipment Conditions

2-873 Tracks removed

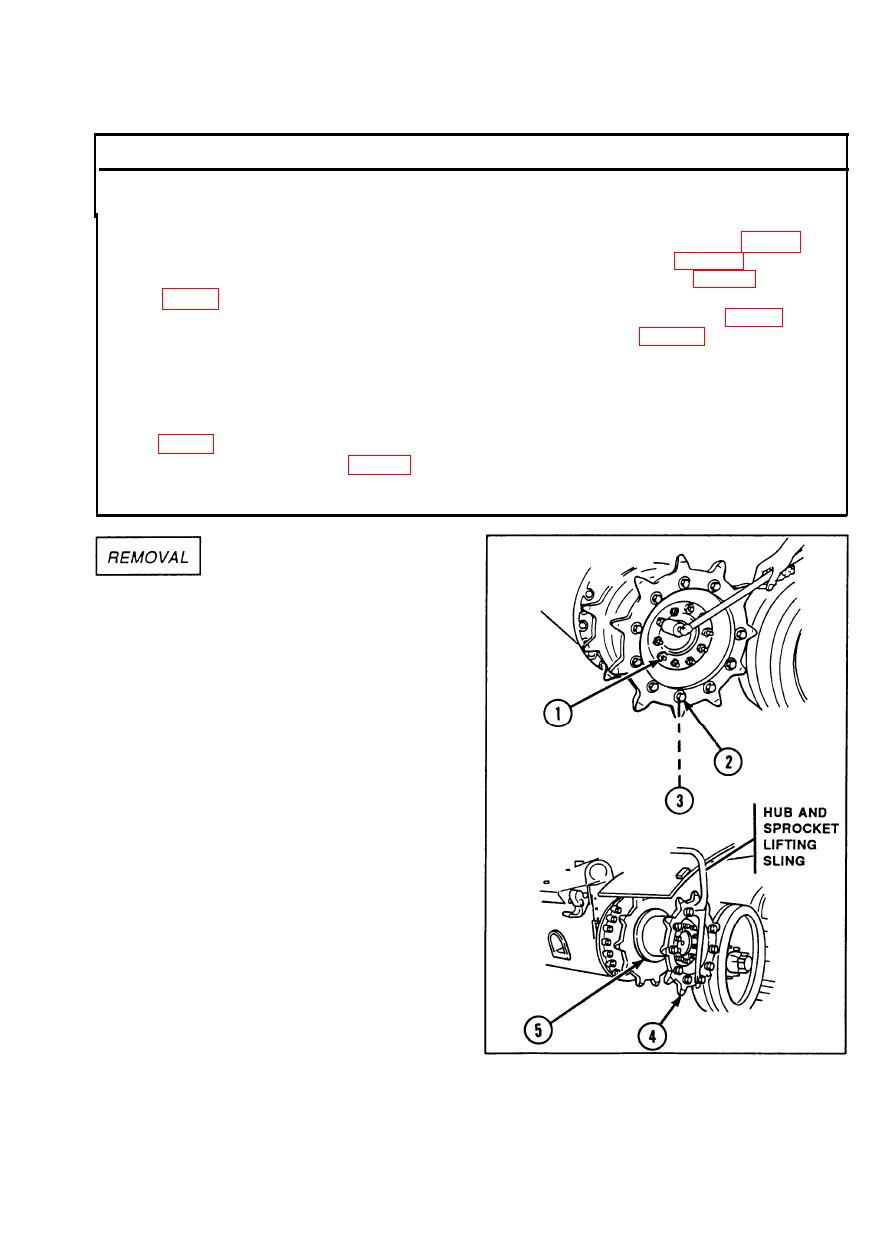

NOTE

The following procedures are written

and illustrated for the left drive hub

sprocket, but apply to both the left

and right drive hub sprockets.

1

Remove ten nuts (1).

Remove three hexagon head capscrews

2

(2) and three Iockwashers (3) properly

spaced to align with mounting holes in hub

and sprocket lifting sling.

Using three removed hexagon head

3

capscrews (2), attach hub and sprocket

lifting sling to sprocket wheel (4).

Attach hoist to hub and sprocket lifting

4

sling, and remove drive hub sprocket (5).

Remove sling from sprocket wheel (4).

2-869

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |