|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-202-14&P

4-38.

HYDRAULIC BRAKE ACTUATOR ASSEMBLY REPLACEMENT (CONTINUED).

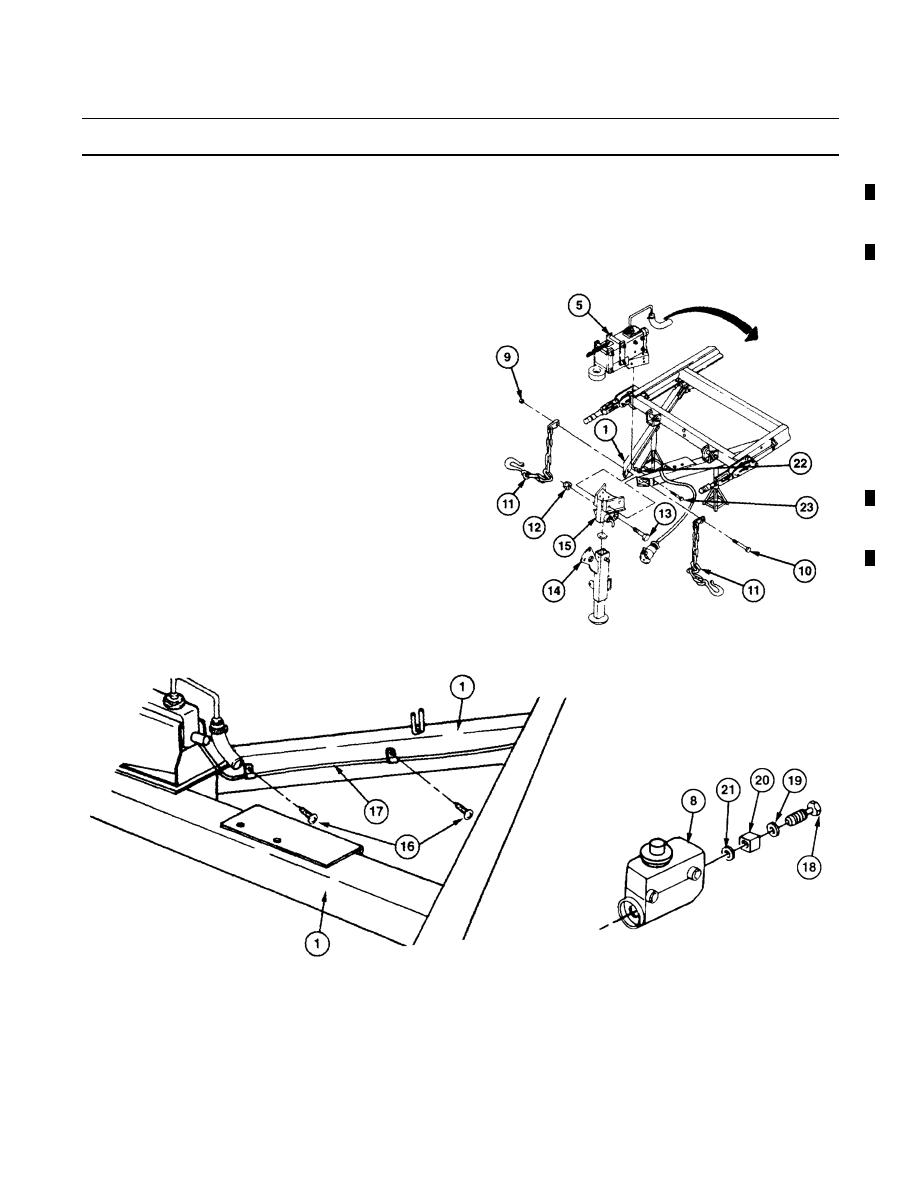

2.

Position hydraulic brake actuator assembly (5) with drawbar bracket assembly (15) at two drawbars

(1).

3.

Install four capscrews (23) and new self-locking nuts (22) on hydraulic brake actuator assembly (5),

drawbar bracket assembly (15), and two drawbars (1). Torque self-locking nuts between 44 and 54

Ib-ft (60-73 Nm).

4.

Install washer (21), connector (20), washer

(19), and fluid passage bolt (18) on master

cylinder (8). Torque fluid passage bolt

between 35 and 40 Ib-ft (47-54 Nm).

5.

Install hydraulic line (17) on curb-side draw-

bar (1) with two screws (16).

NOTE

Bracket and adjustable front support leg

is a one-piece welded assembly.

6.

Install bracket with front support leg (14) on

drawbar bracket assembly (15) with cap-

screw (13) and new self-locking nut (12).

7.

Install two safety chains (11) on hydraulic

brake actuator assembly (5), drawbar

bracket assembly (15), and two drawbars

(1) with two capscrews (10) and new self-

locking nuts (9). Torque self-locking nut

438-087

between 165 and 175 Ib-ft (224-237 Nm).

438-081

438-088

Change 2

4-71

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |