|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-360-20-2

CAUTION

The pawl must be pulled out when

rotating the manual adjusting nut.

Failure to comply will result in

damage to slack adjuster.

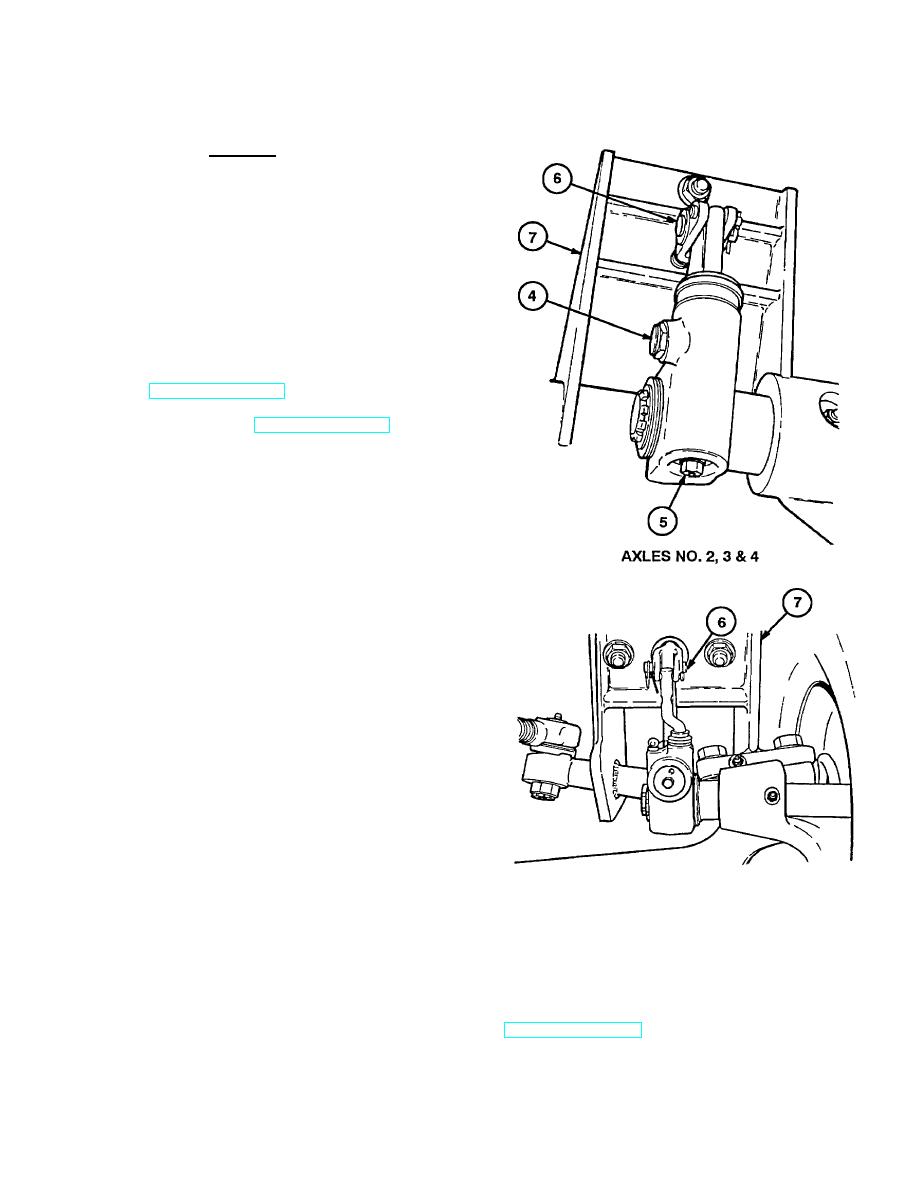

(4) Pull pawl (4) out while turning adjusting

screw (5) clockwise until tight.

(5) Pull pawl (4) out while turning adjusting

screw (5) counterclockwise 1/2 turn.

(6) Start engine an d build system air pressure

to

120-125

psi

(827-862

kPa)

(TM 9-2320-360-10).

(7) Shut off engine (TM 9-2320-360-10).

(8) Measure distance between center of large

clevis pin (6) and brake chamber bracket

(7) with brake treadle released. Record

measurement.

(9) Measure distance between center of large

clevis pin (6) and brake chamber bracket

(7) while assistant holds brake treadle

down. Record measurement.

NOTE

If air chamber stroke is not within

specifications, turn adjusting screw

clockwise 1/8 turn and repeat steps

(8) thru (10).

(10) The difference between measurements

made in step (8) and (9) is the air

chamber stoke. Air chamber stroke must

be 2 in. (50 mm), or less when properly

adjusted.

(11) Pull out PARKING BRAKE control (1) to

apply brakes.

AXLE NO. 1

b. Follow-On Maintenance

(1) Remove wheel chocks.

(2) Drive HET Tractor and check service brake operation (TM 9-2320-360-10).

Change 3 11-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |