|

|||

|

|

|||

|

Page Title:

OIL PUMP AND FRONT SUPPORT INSTALLATION - CONTINUED |

|

||

| ||||||||||

|

|

TM 9-2320-269-34-1

TRANSMISSION SUBASSEMBLIES - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

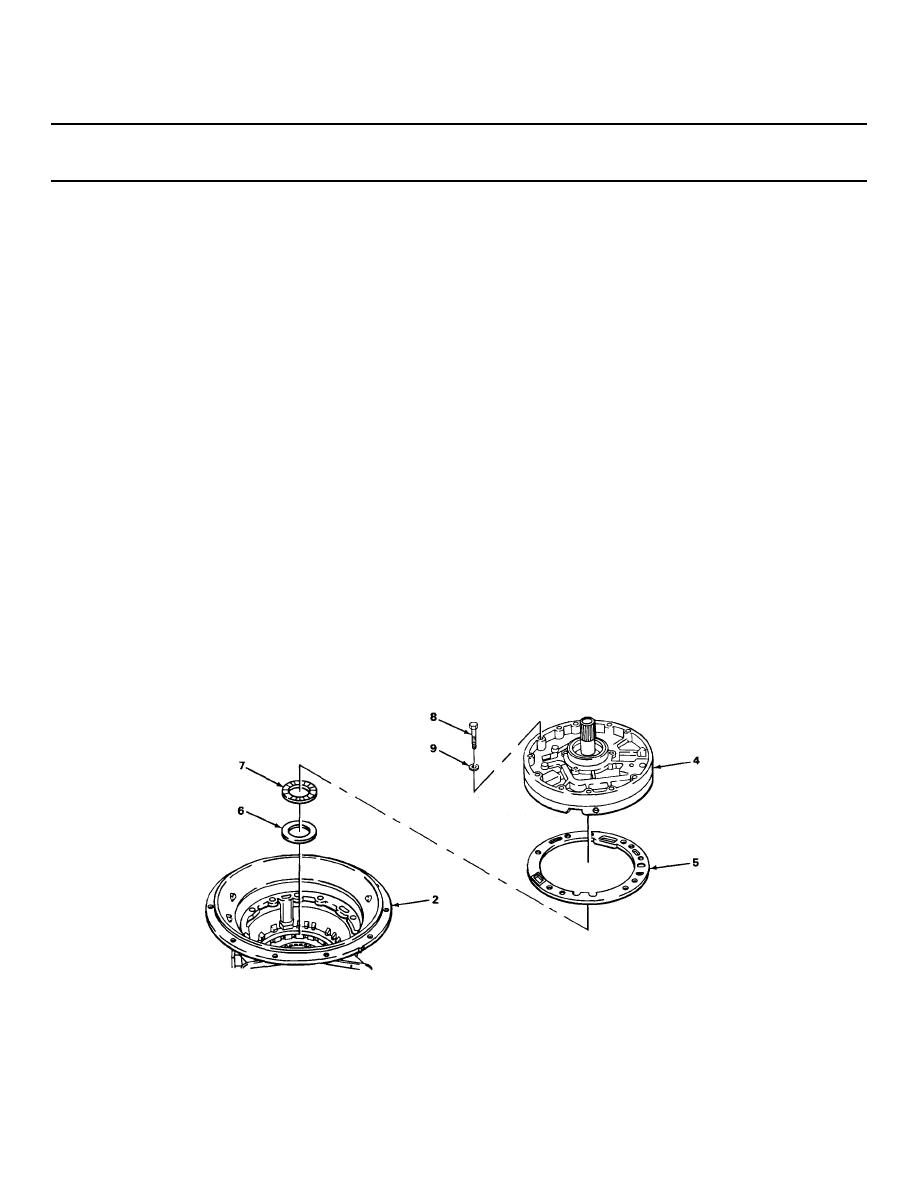

OIL PUMP AND FRONT SUPPORT INSTALLATION - CONTINUED

116.

Transmission

Oil pump and front

a. Screw in two 3/8-16 x 6-inch guide

housing (2)

support assembly (4)

screws into opposite sides of trans-

mission housing.

b. Attach front support lifter to front

support assembly ground sleeve.

c. Attach portable floor crane to front

support lifter.

d. Aline holes with guide studs and holes

in gasket and transmission housing.

e. Using hoist, lower into place.

f. Remove lifting equipment.

117.

Oil pump and front

12 screws (8) and

a. Screw in.

support assembly (4)

new washers (9)

b. Screw in, until snug using 9/16-inch

socket, 6-inch extension, and ratchet

handle with 1/2-inch drive.

c. Replace two guide studs with screws and

washers, and screw in until snug.

d. Using 9/16-inch socket, 6-inch exten-

sion, and torque wrench with 1/2-inch

drive, tighten two screws 180 degrees

apart to 15 ft-lb (20.3 N m) of torque.

e. Repeat with two screws 90 degrees a-

round circle.

f. Tighten remaining screws in pairs 180

degrees apart.

g. Repeat entire operation and torque

all screws to 24 - 32 ft-lb (32.5 -

43.4 N m).

TA238420

2-685

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |