|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1300-277

cap is inserted in well and cap wires are tied around the

(2) The duPont Blaster's Multimeter Model

charge by two-half hitches (fig. 5-13). As an alternate

101 may be substituted for the No. 47 radio pilot lamp

method, use tape to secure blasting cap to prevent

when testing for extraneous electricity, but will not

blasting cap withdrawal.

detect RF energy. Distances prescribed in TM 9-1300-

206 or DARCOMR 385-100 should be used as a guide

in the selection of sites for electric blasting operations in

the vicinity of RF energy transmitters.

c. Splice free end of cap lead wire to free end of

firing wire.

WARNING

NEVER TRY TO FORCE A CAP INTO

CAP WELL THAT IS TOO SMALL TO

Figure 5-13. Two half hitches.

ADMIT THE CAP EASILY.

(2) M1 chain demolition block. Tape an

d. Priming will be accomplished by one of the

electric blasting cap to one of the free ends of the

following methods, determined by the type of explosive

detonating cord chain. The explosive end of the cap will

used.

point toward the chain demolition block.

(1) Charges having cap wells.

Charges

(3) Plastic explosives composition C. Plastic

having cap wells (threaded or unthreaded) may be

explosive charges not having cap wells will be primed

primed as follows:

by forming a cap well in the charge using the pointed leg

of the M2 crimper and inserting blasting cap into the

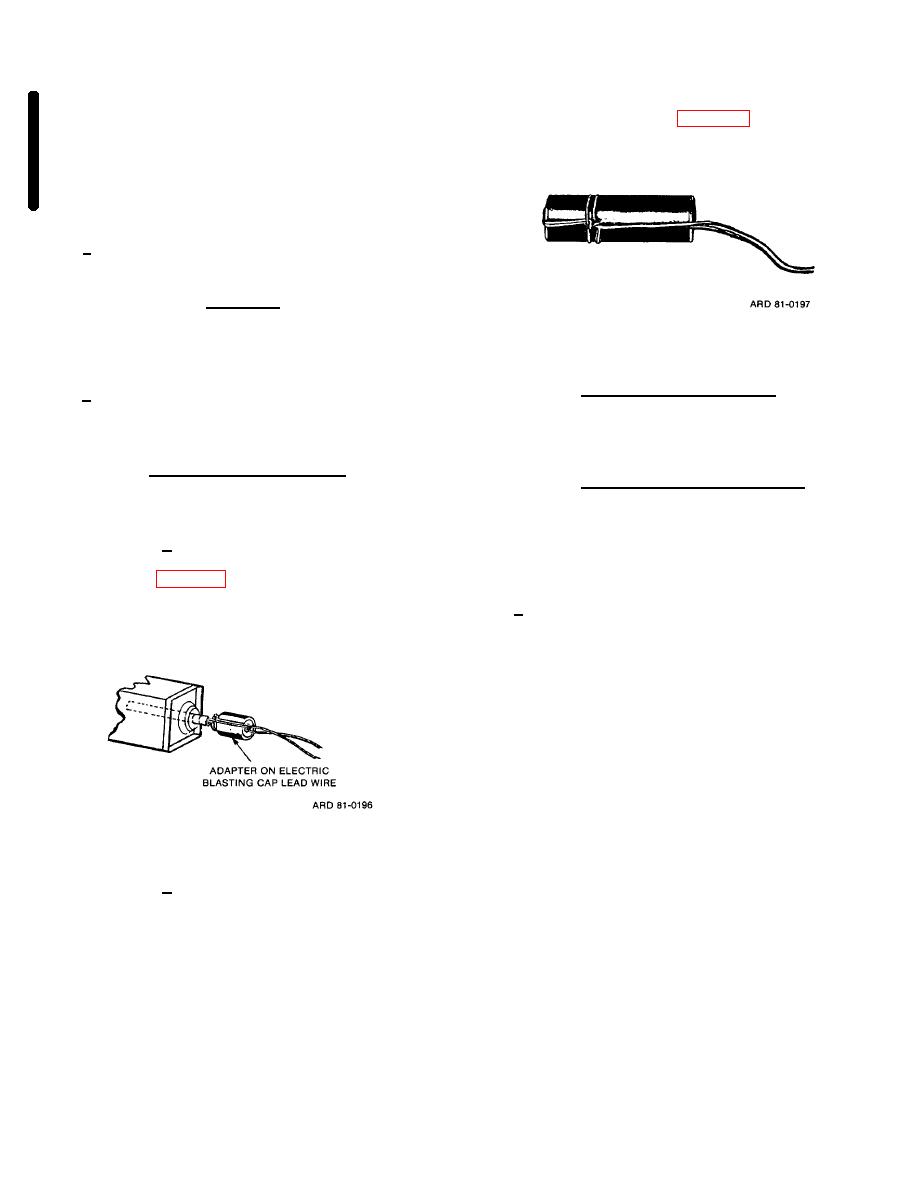

(a) Use of blasting cap with priming

formed cap wells. Composition C-4 should then be

adapter. The cap lead wires are passed through the slot

molded around the blasting cap.

of the adapter (fig. 5-12) and blasting cap is pulled into

place in adapter. The cap and adapter are then inserted

e. The firing circuit will be tested as follows (fig. 5-

into cap well of the demolition charge and adapter is

14).

screwed into place.

(1) Ensure that all joints and bare sections

are separated and placed out of contact with the ground

and all other conductors.

(2) Hold one end of firing wire to one post of

galvanometer and touch other end to other post.

(3) Circuit is complete if needle moves

across scale. The amount of deflection of needle

depends on length and type of firing wire and number of

Figure 5-12. Priming adapter.

blasting caps in the firing circuit. If test indicates a

break or high resistance, shunt the wires and then repair

wire or connections. Caps will be retested if necessary.

(b) Use of blasting cap without priming

adapter. When priming adapters are not available or

demolition charge does not have a threaded cap well,

Change 2

5-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |