|

|||

|

|

|||

|

Page Title:

CHAPTER 5 FIRING SYSTEMS PROCEDURES |

|

||

| ||||||||||

|

|

TM 9-1300-277

CHAPTER 5

FIRING SYSTEMS PROCEDURES

blasting fuse and cap prior to

5-1. GENERAL

insertion into the cap well of the

This chapter contains general operating procedures for

explosive, IF, the safety pin is still

both the nonelectric and electric firing systems. It also

installed.

includes procedures for priming charges, use of

detonation cord, dual firing systems, preparation and

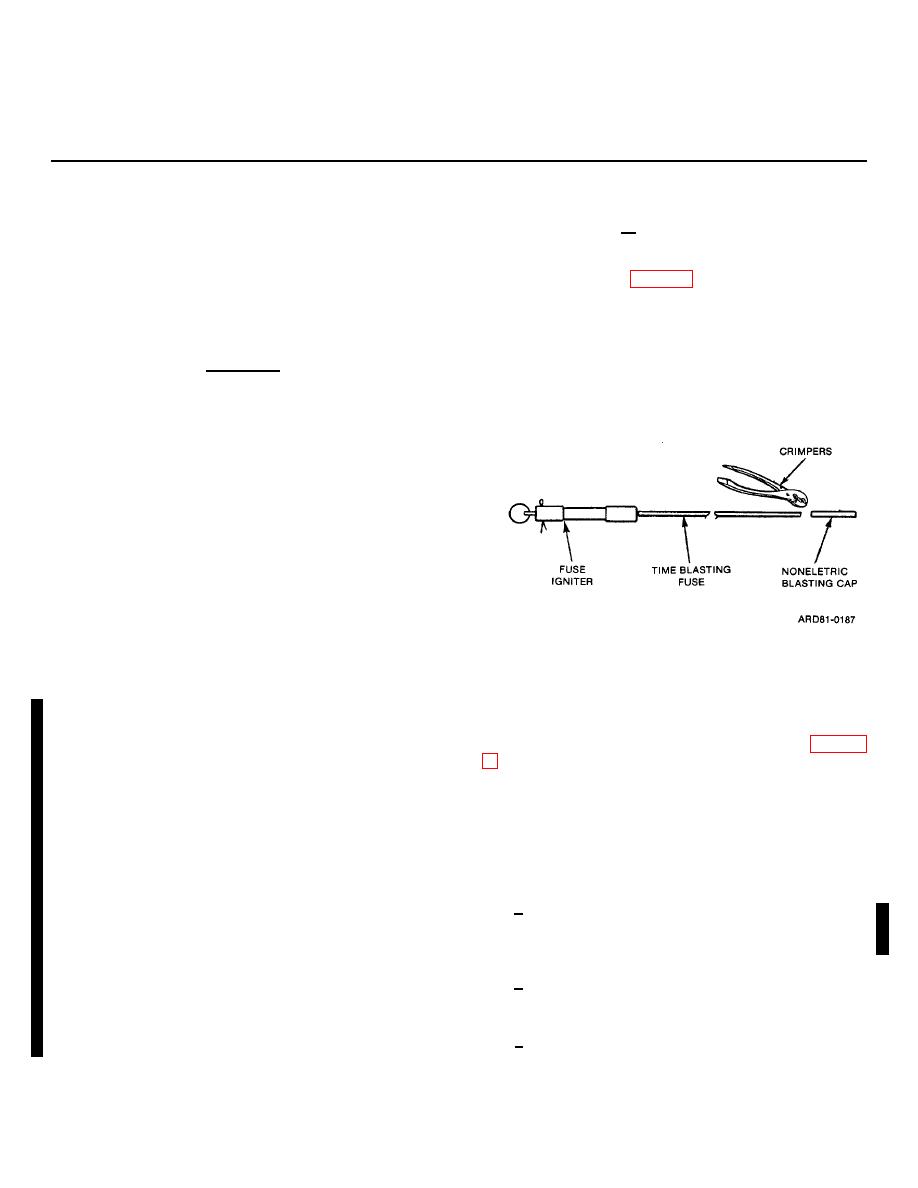

A nonelectric system (fig. 5-1) consists of a fuse igniter,

use of ignition trains, and prevention and handling of

time blasting fuse, and nonelectric blasting cap. Upon

misfires. More detailed information can be found in FM

activation, the fuse igniter initiates the time blasting fuse

5-25 and TM 9-1375-213-12.

which transmits the flame that fires the blasting cap.

The blasting cap provides a shock adequate to initiate

WARNING

the explosive charge. When more than one charge

The preferred firing system for

must be detonated simultaneously, the nonelectric

system must be combined with detonating cord (pars.

demolition is the electric firing

5-12 through 5-16) to ensure simultaneous firing.

system. When the electrical system

is not feasible, or when there is an

electromagnetic radiation hazard

present, the nonelectrical firing

system will be used.

When items to be detonated are

covered with earth, blasting shall not

be buried beneath ground level with

the initiating charge. The initiating

explosives should be primed with

primacord of sufficient length to

reach up through the covering to a

point where the blasting cap may be

Figure 5-1. Nonelectric firing system.

connected above the ground level.

5-3.

SAFETY PRECAUTIONS FOR NONELECTRIC

5-2. NONELECTRIC SYSTEMS

FIRING SYSTEMS

NOTE

In addition to the general safety requirements in Chapter

A nonelectric priming system will

normally be assembled in the field at

the use of nonelectric firing systems.

the demolition site.

Under some

circumstances, if desired, some

NOTE

subassembling may be done in

Blasting

caps

less

than

the

advance in order to save time or to

equivalent of a commercial No. 8 cap

avoid exposing components to rain,

will not be used.

atc.. When it is desired to have 'he

assemblies prepared more than t few

a. The ready supply of nonelectric blasting caps

hours in advance, use blasting cap

should be kept in non-propagating containers/packs.

sealant to waterproof the fuse cap

Blasting caps will be handled near their open ends.

joint. This sealant will protect the

fuse cap joint for an indefinite period

b. Capped time blasting fuses will be handled

of time. The assembly will be treated

carefully so that blasting caps do not contact each other.

as a blasting cap for storage and

transportation (e.g., keep separate

c. The preparation of initiators will be performed at

from other explosives). When using

a distance of not less than 7.5 meters (25 feet) from the

waterproof time blasting fuse igniter

supply of blasting caps or other explosives.

M60, it may be assembled to the

Change 2

5-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |