|

|||

|

|

|||

|

Page Title:

SECTION 3 CONTAINMENT PROCEDURES FOR CHEMICAL CONTAINERS |

|

||

| ||||||||||

|

|

TM 9-1300-275/3

SECTION 3

CONTAINMENT PROCEDURES FOR CHEMICAL CONTAINERS

are built into all l-ton containers. -Tube function

3-1 THE 1-TON CONTAINER.

is to permit venting from one valve while trans-

3-1.1 Identification.

ferring an agent through the other.

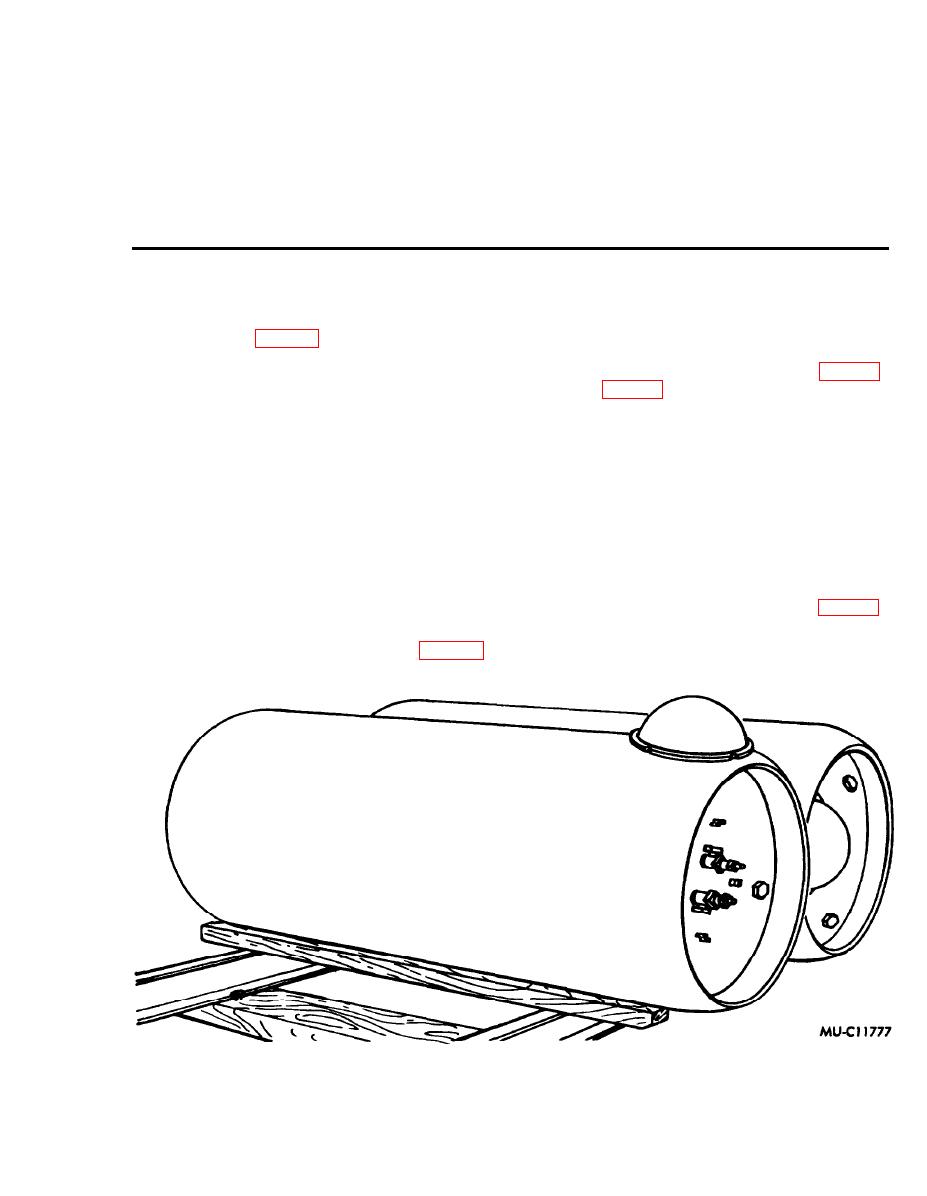

This container (fig. 3-1), identified by its size

3-1.4.2 Valves. These containers are equipped

and recessed ends, is made in two types: A and

with two general types of valves: needle (fig. 3-3)

D which look alike. Type A can be identified by

and angle (fig. 3-4). The needle valve has a -

the serial number and date stamped on its front

inch diameter for type A containers and a l-inch

rim; Type D, by a circular, soldered nameplate on

diameter for type D. The angle valve is of l-inch

its rear head. Type A containers are used only for

diameter only because it cannot be used on type

agents that are gaseous. Type D is used for all

A containers.

agents.

a. The needle valve is used with CC, CK, and

3-1.2 Dimensions and Weights.

CL since these agents are gaseous at atmospheric

These containers have a weight (empty) of 1,600

pressures and tend to build up high pressure.

pounds; a working capacity of 170 gallons; a

b. The angle valve is used with mustard and

length of 81 inches; and a diameter of 30

nerve agents because they require a valve that

inches.

permits less restricted flow of the agent.

3-1.3 Hazards.

3-1.4.3 Plugs. Each l-ten container has six

Agent leaks from valves, plugs, or seams.

plugs, three evenly spaced in each head (fig. 3-5).

To prevent an explosion from excessive pressure,

3-1.4 Principles of Operation.

fusible plugs with lead-alloy cores are used when

3-1.4.1 Eduction Tubes. These tubes (fig. 3-2)

Figure 3-1. 1-Ton Container.

19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |