|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1270-219-13&P

insulation,

broken

wires,

kinks,

or

sharp

(6) Painted surfaces must be free of bare spots.

bends.

(7) Operating controls must function smoothly.

Materiel must be free of burrs, particularly

(3)

those on functional surfaces.

(8) Identification plates must be present and

secure.

(4)

Parts must not be cracked, bent, distorted,

or damaged, and must be free of detrimental

components for

improper

wear.

(9)

Inspect

electrical

functions,

physical

damage,

and

missing

parts.

Rivets must be tight.

(5)

Section

III.

FUNCTIONAL

TESTS

F u n c t i o n a l tests as specified in this section will

( 2 ) Functional Tests

be performed on the AADS or LAI to confirm a fault

Angular Outputs Accuracy Test

reported

by

AVUM

level

and

on

the

EPU

as

a

final

(a)

inspection

after

troubleshooting.

An

EPU

failing

any

test

will be subjected to the troubleshooting procedure specified

Heater Test

(b)

i n Section IV. An AADS or an LAI failing any test will be

returned

to

Depot.

Before

starting

the

test

procedure,

(c)

T e m p e r a t u r e Sensor Initial Check

verify the performance of the tester, Pitot Static Systems,

in accordance with TO 33D-2-6-9-11.

(d)

Static Pressure Leak Test

(e)

5-4. Testing of the Airspeed and Direction Sensor.

Static Pressure-path Flow Test

a. T e s t

R e q u i r e m e n t s . To confirm a fault reported

(f)

Pitot Pressure Leak Test

by AVUM the AADS will be subjected to the following

t e s t s . Any AADS which fails any test will be returned to

Pitot Pressure-path Flow Test

(g)

Depot for repair.

Temperature Sensor Resistance Test

(h)

( 1 ) Preliminary Tests

(a) Bonding Resistance Test

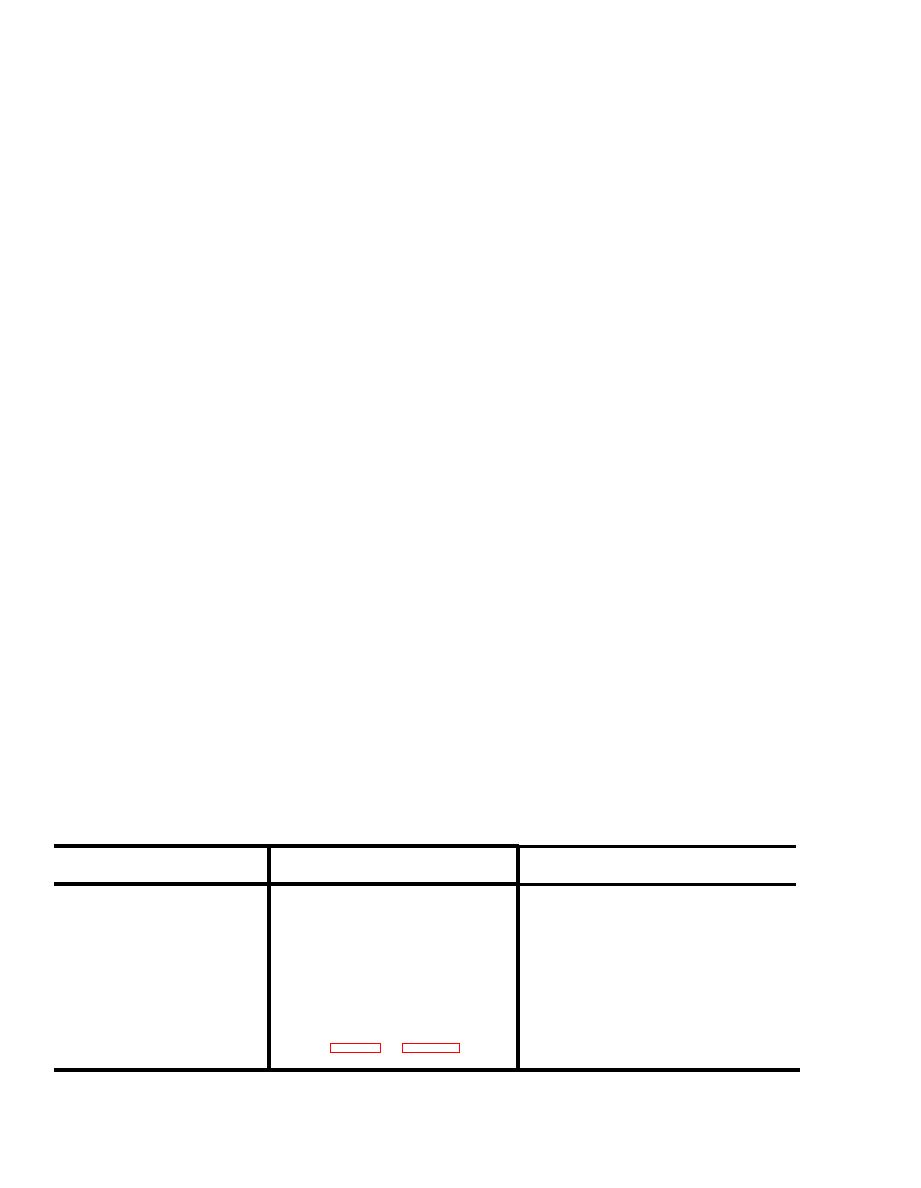

b. T e s t E q u i p m e n t R e q u i r e d

Nomenclature

Part No.

NSN

Test Station ADS (LRU)

95-112-02

4931-01-074-3322

MB-1A

Tester, Pitot Static Systems

Voltmeter, Digital

1430-00-366-8753

8125A

AN/USM

233

Stopwatch

CG-S-764-T1-C2

60SK6240

C a p a c i t y Tank

(Local

Manufacture)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |