|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-1240-322-34&P

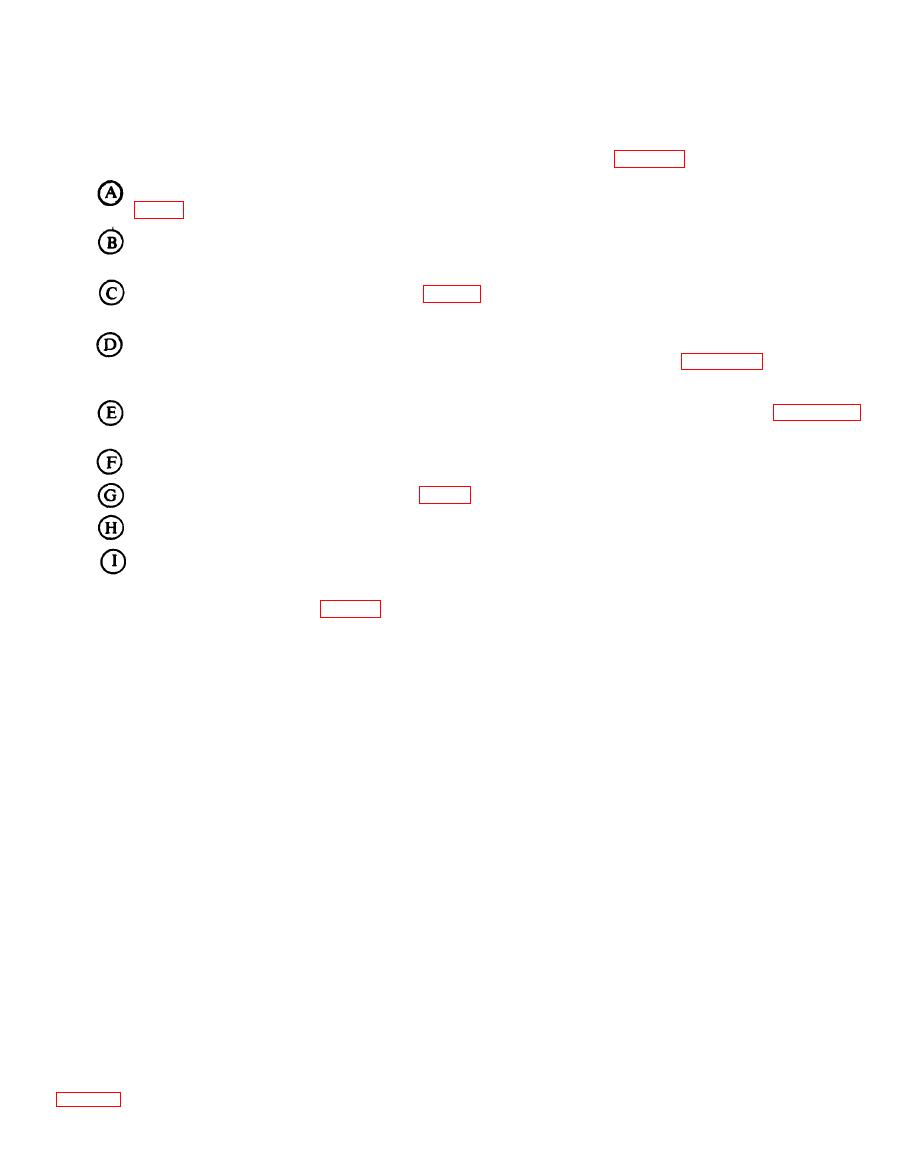

H O W TO TROUBLESHOOT

The following steps tell you how to troubleshoot. A diagram of these steps is on page 1-3.

Do a visual check and list any faults on DA Form 2404 before making repairs. See Vol II,

If you see any faults that may affect the checkout procedure, fix them now. This does not

mean small things like painting scratches.

Do the checkout procedure in Vol I, Chap 2 from the beginning until you find a fault

symptom.

When a fault is found, go to the chapter noted and follow the maintenance procedure given

there. If you already know the fault, look at the fault symptom index in Chapter 3 of this

volume. This will also tell you what to do.

After the bad part has been repaired or replaced, do the checkout procedure in Chapter 2

again. This is to make sure the new part has fixed the problem.

If all the faults are now corrected, do the maintenance tasks on DA Form 2404.

Do the final inspection given in Vol II, Chap 5.

The job is over and the good assembly is sent back to service.

If all faults were not corrected after step E, the bad assembly is sent back to the depot for

repair.

The sample fault isolation procedure (para 1-5) shows you how to use the flow charts in this volume.

Vol I

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |