|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 55-1520-238-S

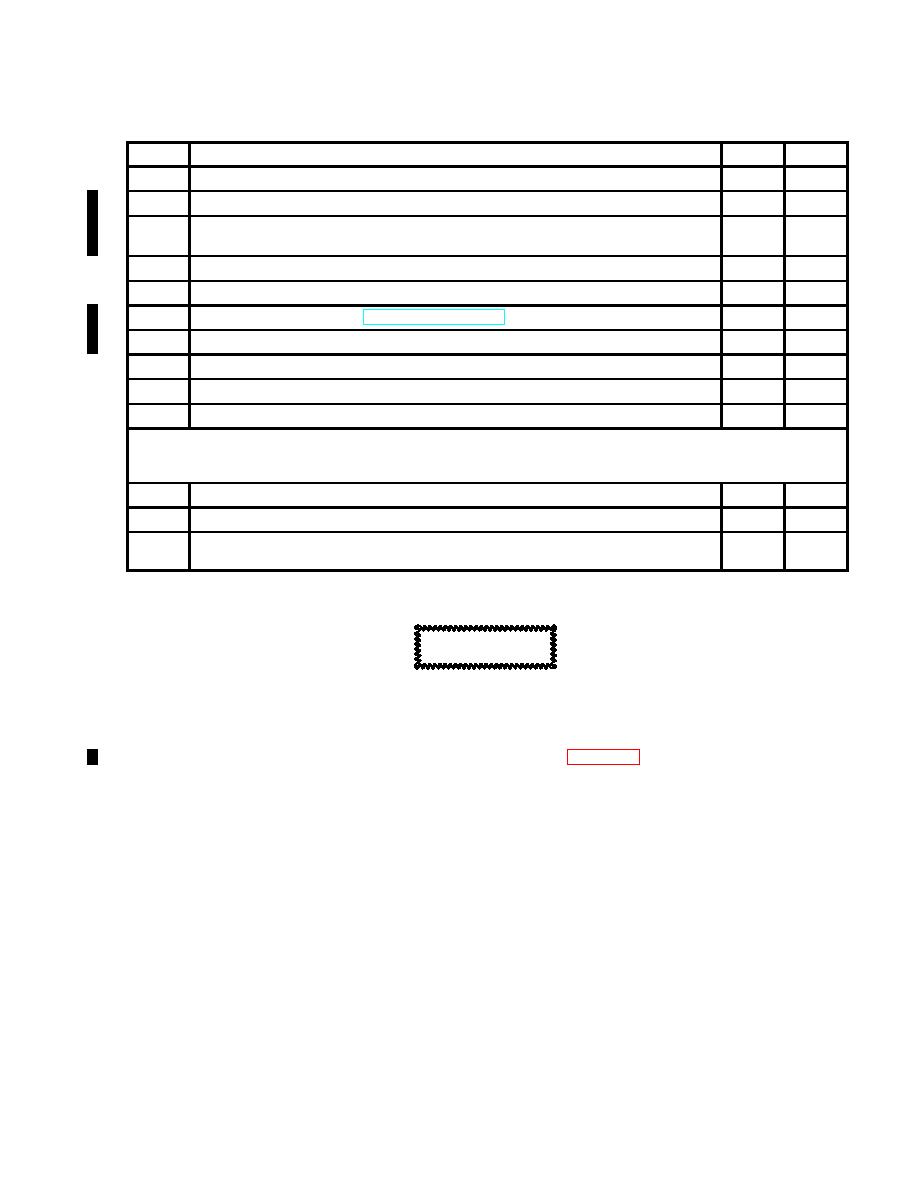

Item

Item Description

Mech

Insp

1.

Ground helicopter. TM 1-1520-238-23

2.

Perform helicopter safety check. TM 1-1520-238-23

3.

Deactivate armamentM230 guns must be cleared and visually checked.

TM 9-1090-208-23-1

4.

Fire truck/fire fighting equipment ready for use.TM 55-1520-238-S

5.

Adjust fuel levels. TM 55-1520-238-S

6.

Remove Hellfire launchers. TM 9-1427-475-20

6.1.

Remove rocket launchers. TM 9-1055-460-13&P

7.

Perform test with M6 combustible gas indicator. TM 55-1520-238-S

8.

Cover fuel access, vent and drain areas. TM 55-1520-238-S

9.

Working area well ventilated. TM 55-1520-238-S

After Covering Is Completed

10.

Inspect covering seams for complete bonding. TM 55-1520-238-S.

11.

Tape and film seal removed from fuel vent areas. TM 55-1520-238-S

12.

Make handling instructions entry on DD Form 13872 "FUEL IN TANKS".

Attach form to helicopter. TM 55-1520-238-S

G4 HELICOPTER PREPARATION:

CAUTION

Composite main rotor and tail rotor blades, rubber and plastic surfaces, the

TADS/PNVS unit, and the canopy are heat sensitive. These surfaces must be

completely covered with cushioning material to provide insulation to prevent

serious damage to the helicopter.

Insure that the helicopter is prepared for shipment in accordance with Chapter 3 or 4 of this manual as applicable.

a. Stabilator. Insure that stabilator is at zero degrees.

b. Static Wicks. Loosen static wicks on the trailing edge of the stabilator and wings and rotate them forward

for protection. Reinstall screw.

c. Aircraft Cleaning. Wash aircraft in accordance with this manual. This is necessary to remove corrosive

substances such as dirt, bugs and exhaust residue. It will make the task of helicopter preparation much easier by

providing an oil free surface for the adhesion of tape. A dirty aircraft will take more time to cover.

d. Flyaway Equipment. Install flyaway equipment, except canopy cover, M230 gun and turret cover, and

main rotor aperture cover. Install in accordance withTM 1-1520-238-23.

e. Protect Glass and Canopy. Install foam cushioning material over glass and canopy surfaces to prevent

scratching and protect them from heat. Secure padding with heat shrink tape using care not to apply tape to glass or

plexiglass areas.

f. Seal Vents. Locate all fuel filler ports, drains, and vents, (including auxiliary power unit) and battery vents.

Seal with heat shrink tape and film. These areas must remain sealed throughout the heat shrink process. All but the

fuel vents may remain sealed after the covering process is completed.

g. Preparation of Sharp Edges, Protrusions, and Heat Sensitive Areas. Pad all protrusions and sharp edges

with tape or cushioning material to prevent damage to film during the shrinking process and prevent high stress points

on the film after shrinking.

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |