|

|||

|

|

|||

|

Page Title:

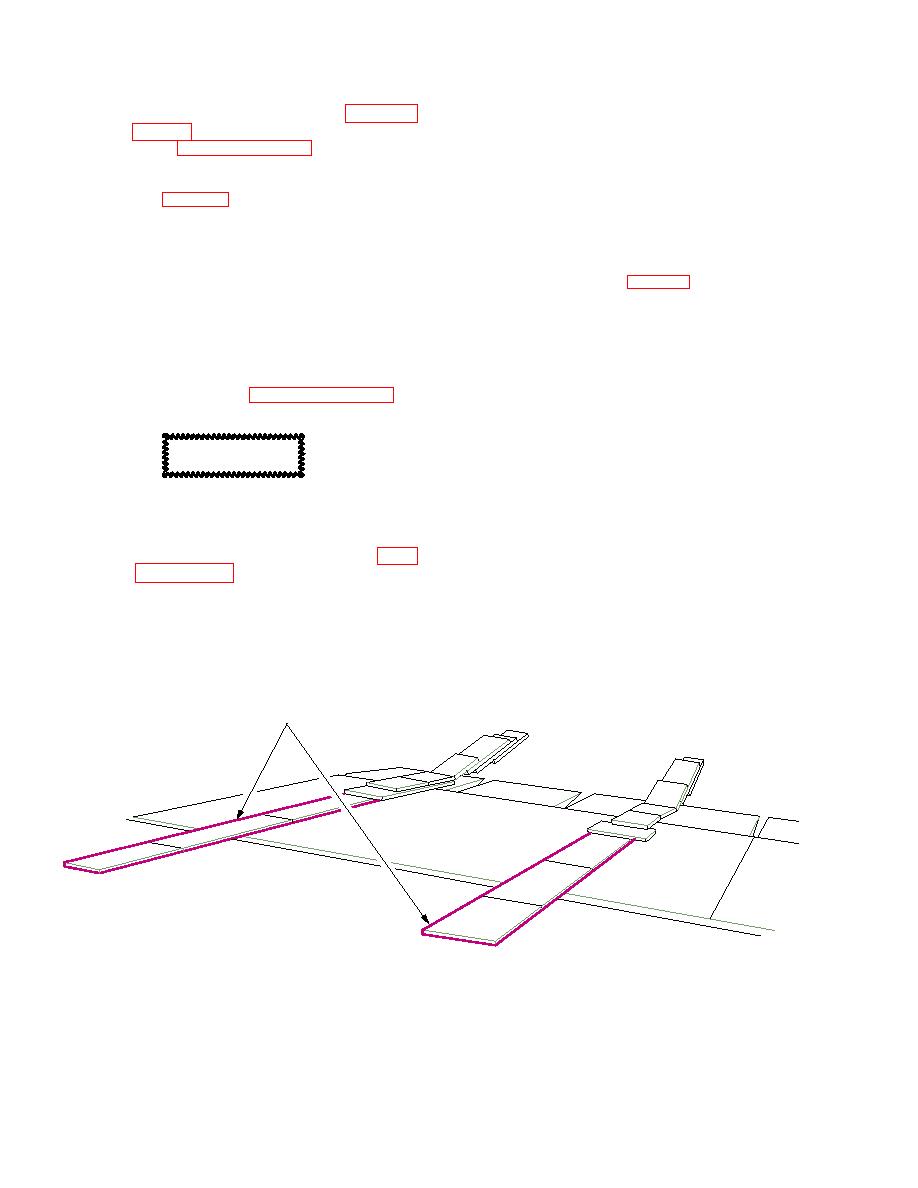

Figure 220. Main Gear Approach Shoring (Rear Door Loading) |

|

||

| ||||||||||

|

|

TM 55-1520-238-S

b. Install

Tail

Wheel

g. Winch Helicopter. Winch helicopter up

cargo loading ramp. Stop winching when

tail wheel reaches FS 1860.

h. Install Safety Chains. Apply helicopter

c Position Shoring. Place two stacks

brakes and install safety chains.

of approach shoring 70 inches apart

i. Position Tail Wheel Shoring. Position a

following:

single stack of step up shoring on cargo

compartment floor with aft end of shoring at

(1) Three pieces of 2 x 12 x 48 inch lumber.

FS 1850. Shoring will provide underbelly

(2) One piece of 12 x 12 x 3/4inch ply-

clearance for helicopter. The shoring stack

wood.

will consist of (fig. 221):

(3) One strip of 12 x 228 x 3/4inch ply-

(1) One piece of 2 x 12 x 120 inch lumber.

wood to protect stowed roller convey-

(2) One piece of 2 x 12 x 96 inch lumber.

ors on cargo aircraft ramp.

(3) One piece of 2 x 12 x 72 inch lumber.

d. Aline Helicopter at Shoring. Position

helicopter with main landing gear wheels

NOTE

alined with shoring.

Secure tail wheel shoring to cargo floor

using CGU1/B cargo straps.

j. Remove Safety Chains. Remove heli-

copter safety chains and release brakes.

CAUTION

k. Winch Helicopter. While carefully moni-

toring underbelly clearance, winch helicop-

ter into cargo aircraft until main landing

Ensure that winch cable does not con-

gear is past ramp crest.

tact components that have been al-

ready loaded on cargo aircraft.

l. Install Safety Chains. Apply helicopter

brakes, place wheel chocks, and install

safety chains.

SHORING TO PROTECT STOWED OMNI-DIRECTIONAL

ROLLER CONVEYORS ON CARGO RAMP EXTENSION.

M05-062

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |