|

|||

|

|

|||

|

Page Title:

Army Unit Responsibilities During Loading. |

|

||

| ||||||||||

|

|

TM 55-1520-238-S

214.2 Army Unit Responsibilities During Loading.

vary depending on tire pressure, strut servicing, and air-

NOTE

craft weight. As a minimum, provide the following (lum-

Once helicopter has been towed to load-

ber sizes are nominal sizes):

ing area, sequence of loading, placement

a. The following approach shoring is required

of equipment and tie down operations will

when loading the helicopter nose first into the airplane

be directed by Air Force personnel. Load-

ing instructions provided are intended

only as a guide.

(1) Five pieces of 12 x 12 x 3/4 inch ply-

wood.

a. Provide shoring as described in paragraph

(2) Eleven pieces of 2 x 12 x 24 inch lum-

ber.

b. Provide personnel to operate helicopter

(3) Eleven pieces of 2 x 12 x 48 inch lum-

brakes during loading and unloading.

ber.

c. Place shoring as directed by loadmaster.

(4) Two pieces of 2 x 12 x 72 inch lumber.

d. Steer helicopter as directed by loadmaster.

b. The following step up shoring is required for

e. Place wheel chocks as directed by load-

the cargo floor when loading the helicopter tail first into

master.

the airplane (fig. 213).

f. Provide manpower for final positioning and

(1) One piece of 2 x 12 x 72 inch lumber.

tie down of helicopter, components, and equipment, as

(2) One piece of 2 x 12 x 96 inch mm lum-

directed by loadmaster.

ber.

g. Load helicopter components as directed by

(3) One piece of 2 x 12 x 120 inch mm

loadmaster.

lumber.

h. Unlock/lock tail wheel as required for heli-

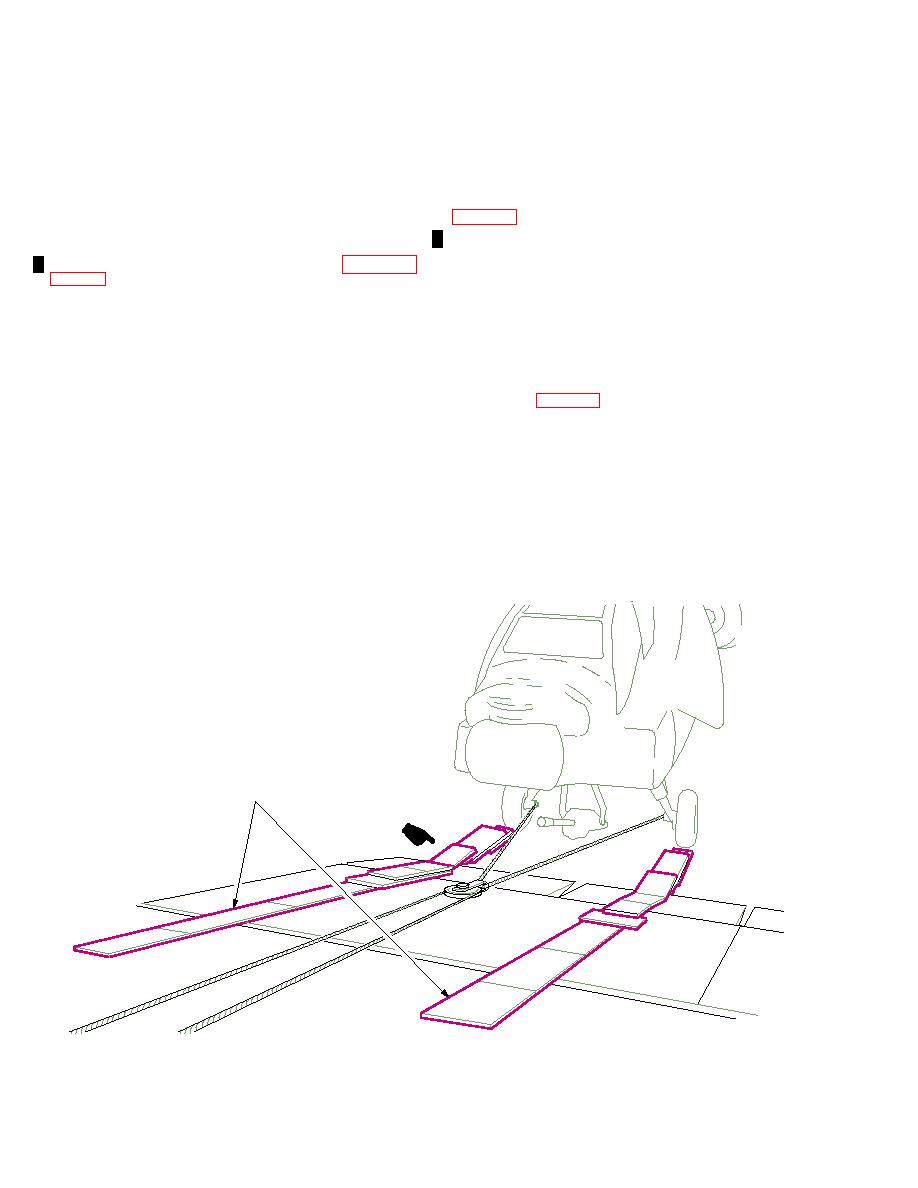

c. Shoring must be provided to protect the

copter maneuvering.

stowed roller conveyor strips on the cargo aircraft ramp

extension. This will require two paths of 1/2-inch ply-

i. Provide additional assistance as requested

wood, 12 inches wide and 228 inches long.

by Air Force loadmaster.

SHORING TO PROTECT STOWED OMNI-DIRECTIONAL

ROLLER CONVEYORS ON CARGO RAMP EXTENSION.

M05-060A

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |