|

|||

|

|

|||

|

Page Title:

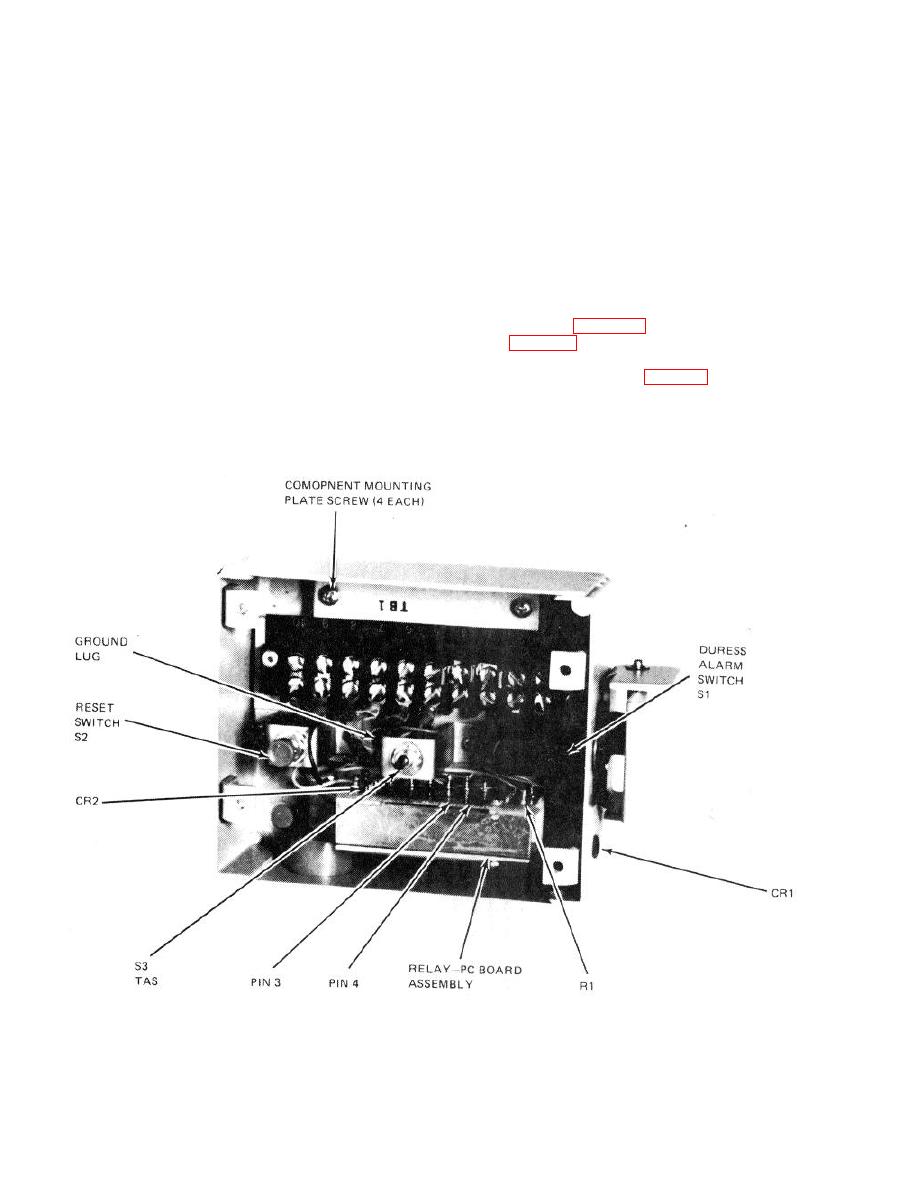

UFigure 5-1. Latching Alarm Switch with Callouts for Troubleshooting Test Points |

|

||

| ||||||||||

|

|

TM 5-6350-264-14&P-8

NAVELEX EE181-AA-OMI-090/E121 SA-1954

T.O. 31S9-2FSS9-1-8

and bits of wire or solder inside the housings.

d. Check all available information on the equipment for

aid in diagnosing problems.

NOTE

e. Make a visual inspection of the equipment.

Touchup paint is recommended instead

(1)

Inspect the equipment for evidence of physical

of refinishing whenever practical.

damage.

(6)

Inspect all metal surfaces intended to be

(2)

Inspect the terminal strips for clean and secure

painted for condition of finish and legibility of

connections.

panel lettering.

(3)

Inspect all wiring and cabling for worn or frayed

f.

Refer to figure 5-1 for all test points referred to in

insulation and broken wires.

including Trouble, Probable Cause, and Corrective

(4)

Inspect all resistors for discoloration due to

Action, are listed in table 5-1.

overheating.

(5)

Inspect the complete subsystem

for

the

presence of dirt, corrosion, moisture,

Figure 5-1. Latching Alarm Switch with Callouts for Troubleshooting Test Points

5-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |