|

|||

|

|

|||

|

Page Title:

Section II. SERVICE UPON RECEIPT OF MATERIAL |

|

||

| ||||||||||

|

|

TM 5-6350-262-14/5

NAVELEX 0967-466-9050

TO 31S9-4-38-1 Chg 3

Section II. SERVICE UPON RECEIPT OF MATERIAL

a.

Inspect the equipment for damage incurred during

2-3. Unpacking

shipment. If the equipment has been damaged, report the

damage on DD Form 6 (para 1-2).

There are no special instructions required for unpacking the

control unit from its shipping container. It is only necessary to

b. Check the equipment against the packing slip to see if the

observe the usual precautions and requirements associated

shipment is complete. Report all discrepancies in accordance

with the handling of precision electronic equipment. The

with paragraph 1-2.

control unit emergency power battery is packaged separately.

It should be removed from its shipping container and fully

charged and tested prior to installation in the Control Unit.

c. Check to see whether the equipment has been modified.

Battery charging and testing instructions are given in chapter

(Equipment which has been modified will have the MWO

number on the front cover.) Check also to see whether all

as instructed in chapter 7.

currently applicable MWO's have been applied. (Current

MWO's applicable to the equipment are listed in USASA PAM

310-6 or DA PAM 310-7 as applicable).

2-4. Checking Unpacked Equipment

Section III. INSTALLATION INSTRUCTIONS

NOTE

The following installation procedure must be made with the assistance of direct support

(intermediate) or general support maintenance personnel.

2-5. Tools, Test Equipment and Materials Required for

the control unit. No special installation tools or equipment are

Installation

required. For '/4-inch bolts, screws, or other type fasteners

(depending on mounting surface material) are required to

securely

attach

the

control

unit.

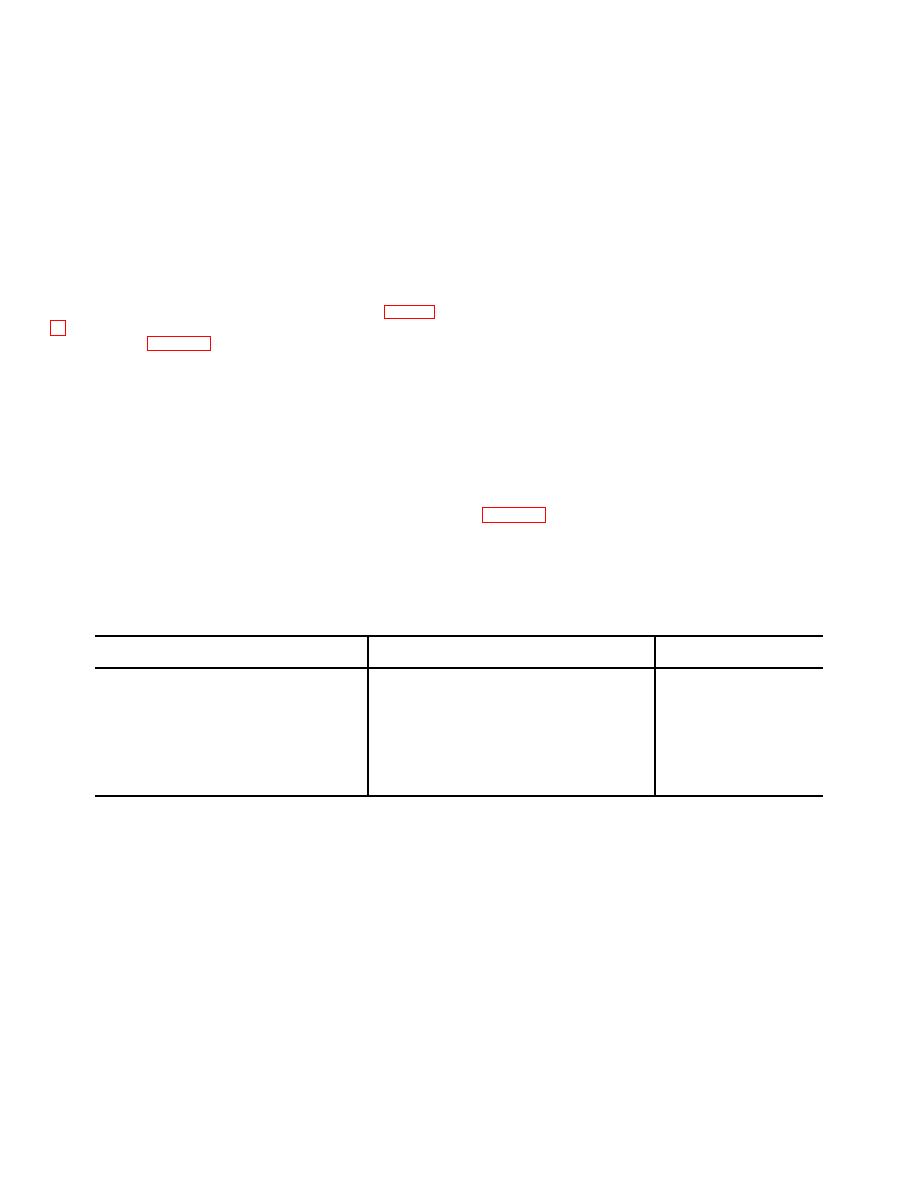

Table 2-1. Installation Tools and Test Equipment

Items

Purpose

Applicable

publication

Power Supply, calibrated 0 to 50 V dc

Testing and trouble-shooting.

(Not available)

output.

VOM,

TS352B,

6625-553-0142

or

Testing and trouble-shooting.

(Not available)

equivalent.

Tool Kit, TK 105G, 5180-610-8177 or

Contains hand tools commonly used in

(Not available)

equivalent.

electronic repair shops.

Stopwatch.

Testing and adjustment of entrance and exit

(Not available)

time delays.

with a 7/8-inch Greenlee chassis punch inserted in a starter

2-6. Installation Instructions

hole made with a small-diameter drill. Do not use a holesaw

as it produces a larger metal shavings than does a small drill.

a. Prior to installing the control unit, wiring and/or conduit

access holes must be cut in the enclosure surfaces so

CAUTION

marked. Access holes must be made within the area clearly

outlined on the enclosure surfaces to prevent unnecessary

Ensure that metal shavings do not fall

damage to internal structure and components. The number,

into the power supply; otherwise the

size, and location of access holes and the location of the

power supply may be damaged.

control unit on the wall should be supplied by system

installation planning personnel. Access holes should be made

Change 3

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |