|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

e. Continue the drying until four consecutive samples

taken from both the top and bottom. To determine the

drying progress, plot curves of load current, top liquid

test at least 26 K V and preferably 30 K V or higher and

temperature, and dielectric strength versus time. A

until a satisfactory "cloud test" is obtained as outlined in

decrease in dielectric strength indicates that moisture is

passing from the winding and insulation into the insulating

f When the drying operation has been completed, the

oil. As the moisture is driven out of the oil, the dielectric

liquid removed for sampling must be replaced. To avoid

strength will increase, indicating that the drying process is

the possibility of entrapping air bubbles in the windings, it

progressing satisfactorily.

is recommended that the oil be returned through the

upper filter press connection.

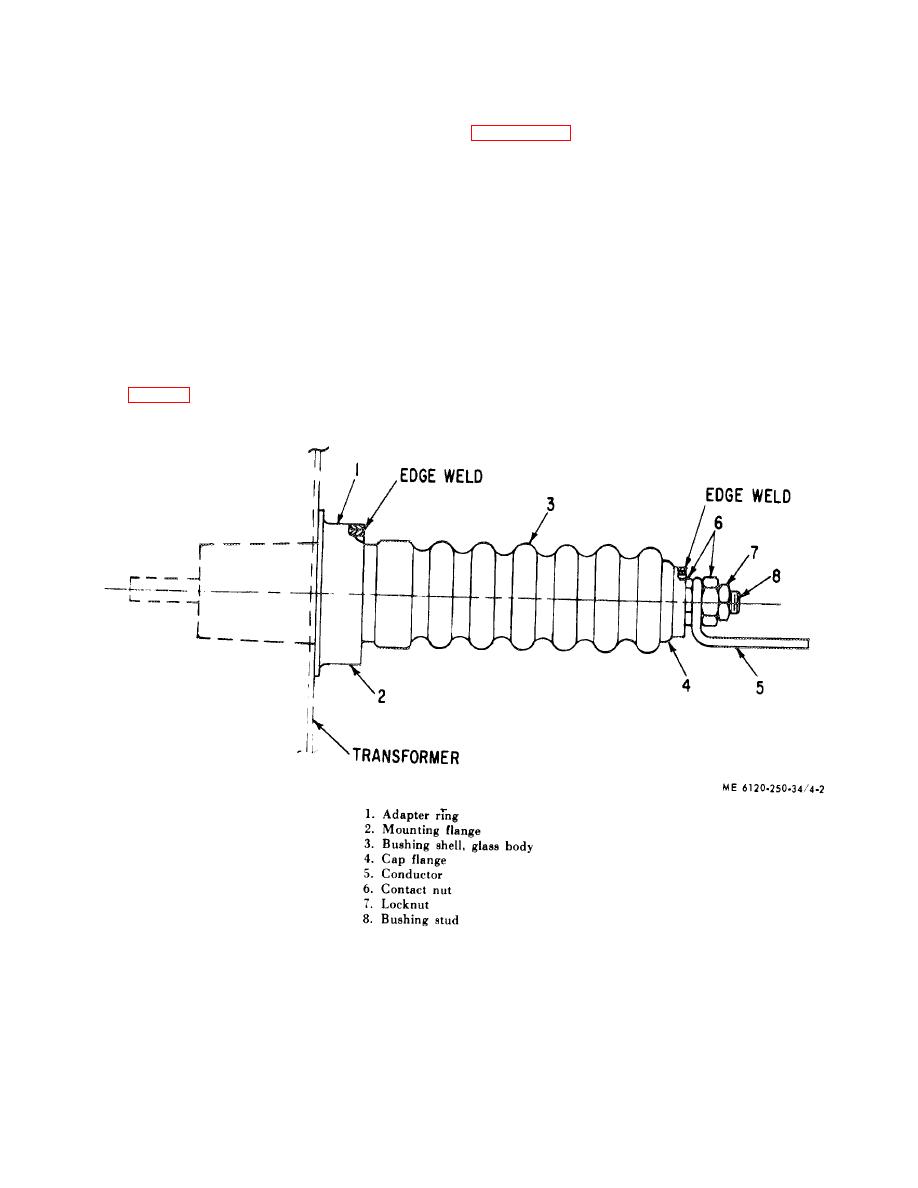

Section II. INSULATOR REPAIR

4-6 General

thermal coefficient of expansion designed to match that of

the metal. The cap flange is fusion-welded to a spinning

High and low-voltage winding leads are brought out

brazed on the bushing stud. The mounting flag is fusion-

through hermetically sealed RE-X glass ceramic

welded to an adapter ring 11 ) which in turn is welded to

bushings. A metal-to-glass seal is established in the

the transformer tank wall, thus completing the bushing

bushing through the use of an oxide treatment of the cap

seal without the use of gaskets.

flange (4, fig. 4-2) and mounting flange (2) prior to

casting, plus a special glass ceramic material having a

Figure 4-2. Transformer RE-X bushing.

4-7. Removing Insulator Bushing.

CAUTION

a. Lower the insulating oil until the level is below the

Before attempting to remove or replace a bushing,

lowest insulator bushing.

thoroughly flush out the air

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |