|

|||

|

|

|||

|

Page Title:

CHAPTER 4 REPAIR OF TRANSFORMER |

|

||

| ||||||||||

|

|

CHAPTER 4

REPAIR OF TRANSFORMER

Section I. TESTING

(b) A clear glass bottle in a lightproof carton.

(c) A one-quart tin can that has had the solder seams

4-1.Leak Test

Inspect the entire transformer for evidence of leaks and

CAUTION

make the following pressure test. Introduce dry nitrogen

Do not use rubber stoppers or rings

through the vent valve (located on the rear tank wall) until

(3) To clean the bottles, rinse with nonleaded,

the pressure in the transformer reaches 5 psi. Seal the

oil free gasoline. Then wash with strong soapsuds, rinse

tank at this pressure and make an examination for leaks

thoroughly with distilled water, and dry in an oven at

over a period of 12 hours. Leaks above the liquid level

1050C to 1100C for at least eight hours. After drying, the

can be located by applying a liquid soap solution to all

bottles must be tightly sealed with glass stoppers or with

gasket joints, pipe fittings, etc.

clean corks protected by clean metal foil. Store them in a

4-2. Tap Changer Test

dry, dust free cabinet or compartment.

The purpose of this test is to determine if the positions are

(4)

Carefully clean the sampling valve and

correct and the steps progress in accordance with the

allow enough insulating oil to run out so that any moisture

transformer nameplate. Apply a low voltage to one

or foreign matter which may have collected in valve and

winding (normally the high- voltage) and measure the

pipe is removed.

voltage on the other winding for each top changer

(5) Rinse the bottle carefully, at least three

position.

times, with small portions of liquid drawn from the

WARNINGS

sampling valve. Allow the sampling bottle to drain

The turns ratio must be taken into

thoroughly between rinses.

consideration when making this test, as

(6) Draw a sample into the bottle, leaving

voltages endangering operating personnel

sufficient air space to allow for possible expansion of the

may be present.

liquid. Reseal the transformer and carefully seal the

bottle to prevent exposure to the atmosphere.

4-3. Testing Insulating Oil for Moisture

(7) When making repeated samplings, observe

a. Handling Insulating Oil.

the transformer liquid level and add additional oil as

(1)

When handling insulating oil, use only

required.

metal or oil-proof synthetic rubber hose for oil lines. The

sulfur in natural rubber hose will dissolve in the oil and

prove harmful to the copper in the windings.

(2) In the sampling and testing of insulating oil,

strict attention should be given to cleaning and drying of

sampling and testing receptacles. Samples should be

taken when the oil is at least as warm as the surrounding

air to avoid the possibility of moisture condensation. If

the transformer is out of doors, the sample should be

taken to guard against contamination by blowing dust, etc.

b. Sampling from Transformer.

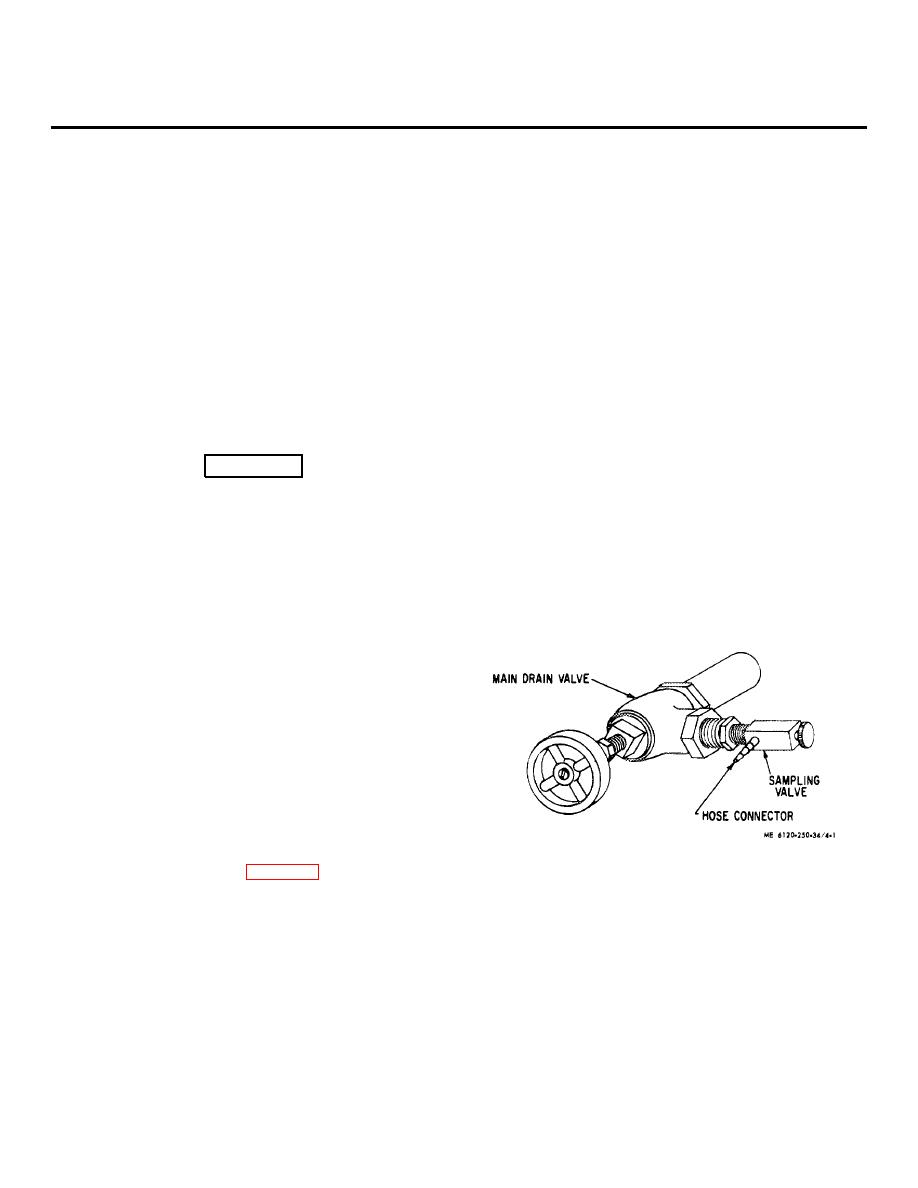

(I) Impurities which tend to affect the dielectric

strength of the oil will generally be found at the bottom of

the transformer, therefore the sampling valve is located

Figure 4-1. Transformer main drain valve.

on the main drain valve. See figure 4-1.

(2) Three types of containers are recommended for

c. Field Test for Moisture Content.

sampling purposes.

(I) Obtain a sample of the insulating oil when

(a) A one-quart small neck brown glass bottle.

4-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |