|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

2-14. Load Break Switch Installation

a.

General.

Prior to installation of switch,

adjustments and alignment checks should be made to

insure proper operation.

CAUTION

To check operation of load break switch it

must be operated slowly with the power

springs blocked. See TM 5-6120-250-12.

b.

Checks and Adjustments.

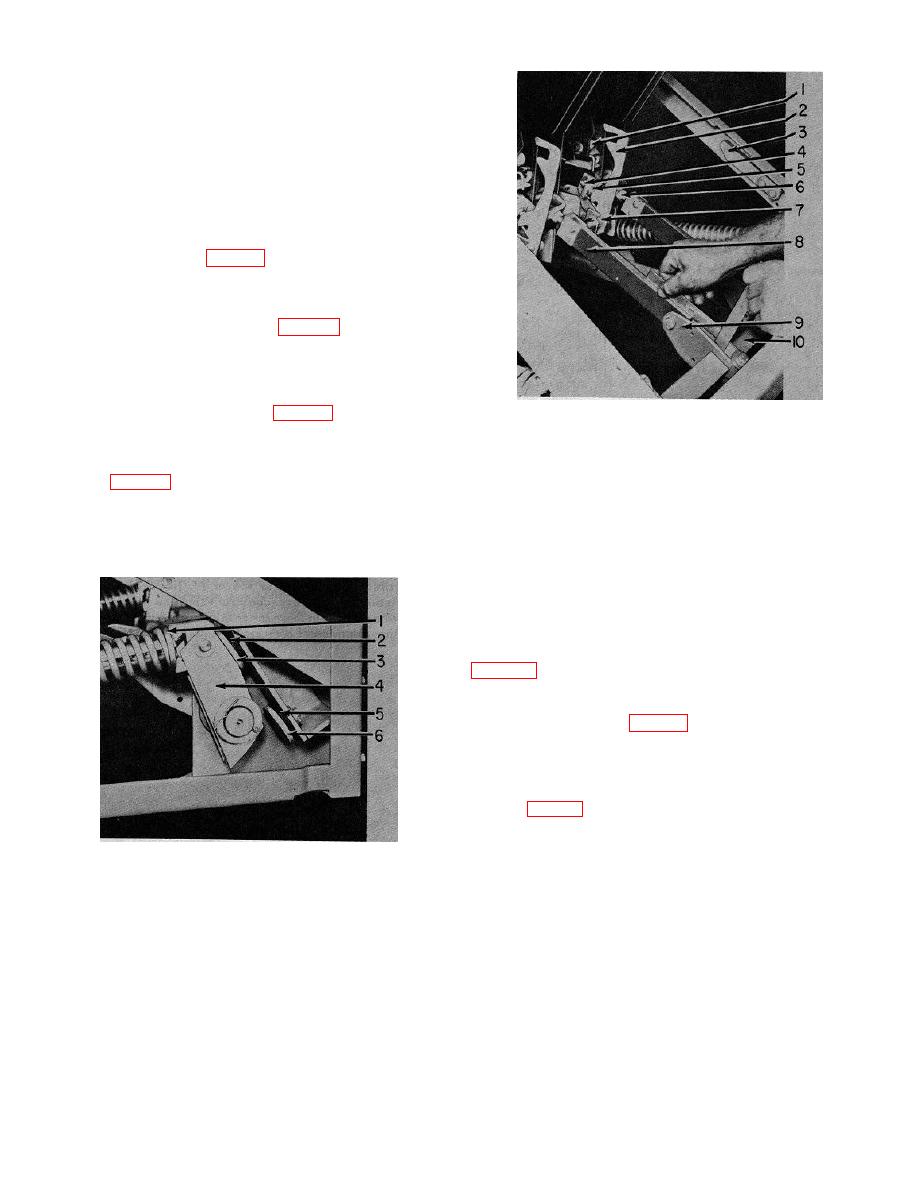

(1) Upper(closed) mechanism stop. The

upper buffer stops, (3, fig. 2-3 ) located on either side of

the mechanism at the ends of the main crank shaft, must

be adjusted to position the operating rod cranks when the

switch is closed. Operate the switch to the fully closed

position. The operating rod (8, fig. 2-4! must go over

toggle approximately 1/l inch at the crank connection,

when the switch is closed. A simple means of measuring

the correct toggle angle is to place a straight edge along

the upper side of the operating rod. Extend it until it is

1. Auxiliary blade spring

over the square main shaft (10, fig. 2-4). The dimension

2. Auxiliary blade release hook

from the straight edge to the closest corner of the square

3. Spring stop

shaft should be 1/4 to 3/8 inch. If adjustment of the stop

4. Cramming screw

is necessary, remove the cotter pin holding the spring

5. Lock nut

stop (3, fig. 2-4). Move washers and metal shims from

6. Adjusting nut

the front to the rear or the reverse) until the proper toggle

7. Release hook spring

angle is obtained. Adjust the stops at both ends of the

8. Operating rod

main shaft the same amount to keep them

9. Operating rod crank

10. Main crank shaft

balanced.

Figure 2-4. Switch blade adjustments.

(2) Primary wipe. The operating rod must

fully close the switch primary blades to obtain the correct

primary finger wipe. With the switch in the closed

position, pull the top of the primary contact blades (I 1,

connection clearances. There should be I / 64 to I / 32

inch clearance between the buffer stop 18) and the

primary blade stop (1, fig. 2-6). There should also be 3/

16 to I / 4 inch between the edge of the primary blade and

the front of the primary contact support. Adjust the length

of the rod by use of the adjusting nut (6, fig. 2-41 to

obtain the 3 / 1 6 to I / 4 inch gap then adjust the buffer

stop (8, fig. 2-5) by adding or removing shims to get the I

/ 64 to I /32 inch clearance.

1.

Collar

2.

Buffer rubber

3.

Upper buffer stop

4.

Booster crank

5.

Buffer rubber

6.

Lower buffer stop

Figure 2-3. Buffer assembly, load break switch

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |