|

|||

|

|

|||

|

Page Title:

Table 2-2. Transformer Troubleshooting |

|

||

| ||||||||||

|

|

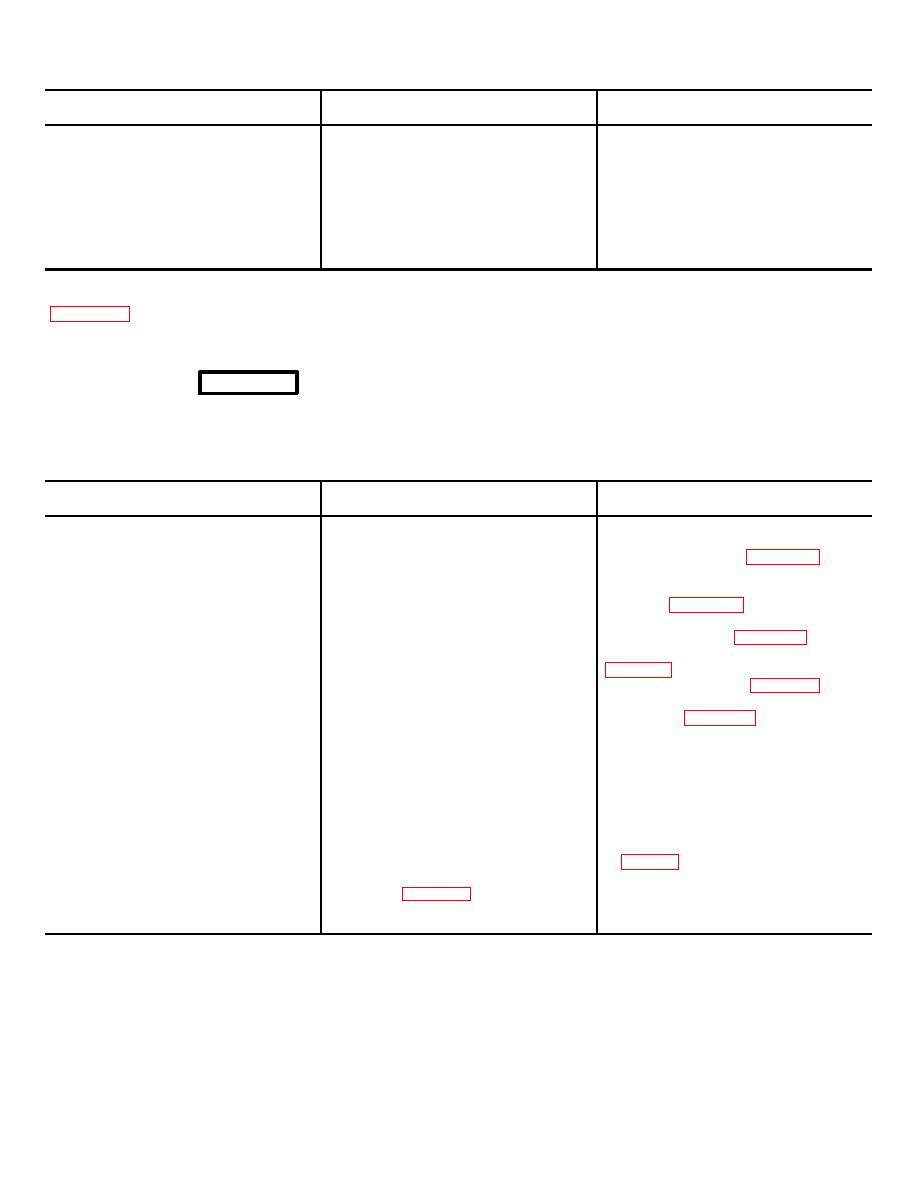

Table 2-2. Transformer Troubleshooting

Malfunction

Probable Cause

Corrective Action

High liquid and/or wind temperature

a. Low liquid level.

a. Check gages for damage, replace if

damaged.

b. Leak of liquid coolant.

b. Check pressure gage reading. (No

change in pressure with a temp. rise

indicates a leak.) Inspect transformer

for leaks.

Report leaks to depot

maintenance.

c. Rise in line load and / or ambient

c. Report to systems engineer.

Temperature.

work is being done on a circuit breaker, make sure

2-6. Circuit Breaker Troubleshooting

that it is in the open position and the closing springs

malfunctions for direct and general support maintenance

are restrained by the safety pin.

personnel.

WARNING

When

inspecting,

removing,

installing

or

maintenance

Table 2-3. Circuit Breaker Troubleshooting

Malfunction

Probable Cause

Corrective Action

1.

Overheating.

a. Contacts not aligned.

a. Adjust. (para. 5-71.

b. Contacts badly burned or pitted.

b. Replace and check adjustment, align-

ment mechanisms. (para. 5-11).

c. Current-carrying surfaces dirty.

c. Clean all current-carrying surfaces.

2.

AK-2 (Feeder) Breaker Fail to

a. Travel of tripping device does not

a. Readjust or replace tripping

Trip.

provide positive release of tripping

device. (para. 5-15, 5-16).

latch.

b. Worn or damaged trip unit parts.

c. Binds in overcurrent trip device.

c. Replace overcurrent trip device.

3.

Failure to Close

a. Binding in attachments preventing

resetting of latch.

b. Latch out of adjustment.

c. Hardened or gummy lubricant.

c. Clean bearing and latch surfaces.

d. Latch return spring too weak or

d. Replace spring.

broken.

4.

Burned Main Contacts.

a. Improper contact sequence (Main

a. Increase arcing contact wipe.

contacts not sufficiently parted

Adjust contact sequence. (pars 5-

When arcing contacts part.

7, 5.9).

b. Loss of contact wipe or pressure

b. Replace stationary contact spring

and dress up or replace contacts.

(para 5-1 1.

5.

Unnecessary Tripping (that is

a. Check tripping device for proper

tripping when tripping should not

setting. (para 5-15).

Occur.)

b. Worn latch (breaker easily jarred

b. Replace with new part.

open)

malfunctions for direct and general support maintenance

2-7. Semi-trailer Troubleshooting

personnel.

Table 2-4

lists the semi-trailer

troubleshooting

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |