|

|||

|

|

|||

|

Page Title:

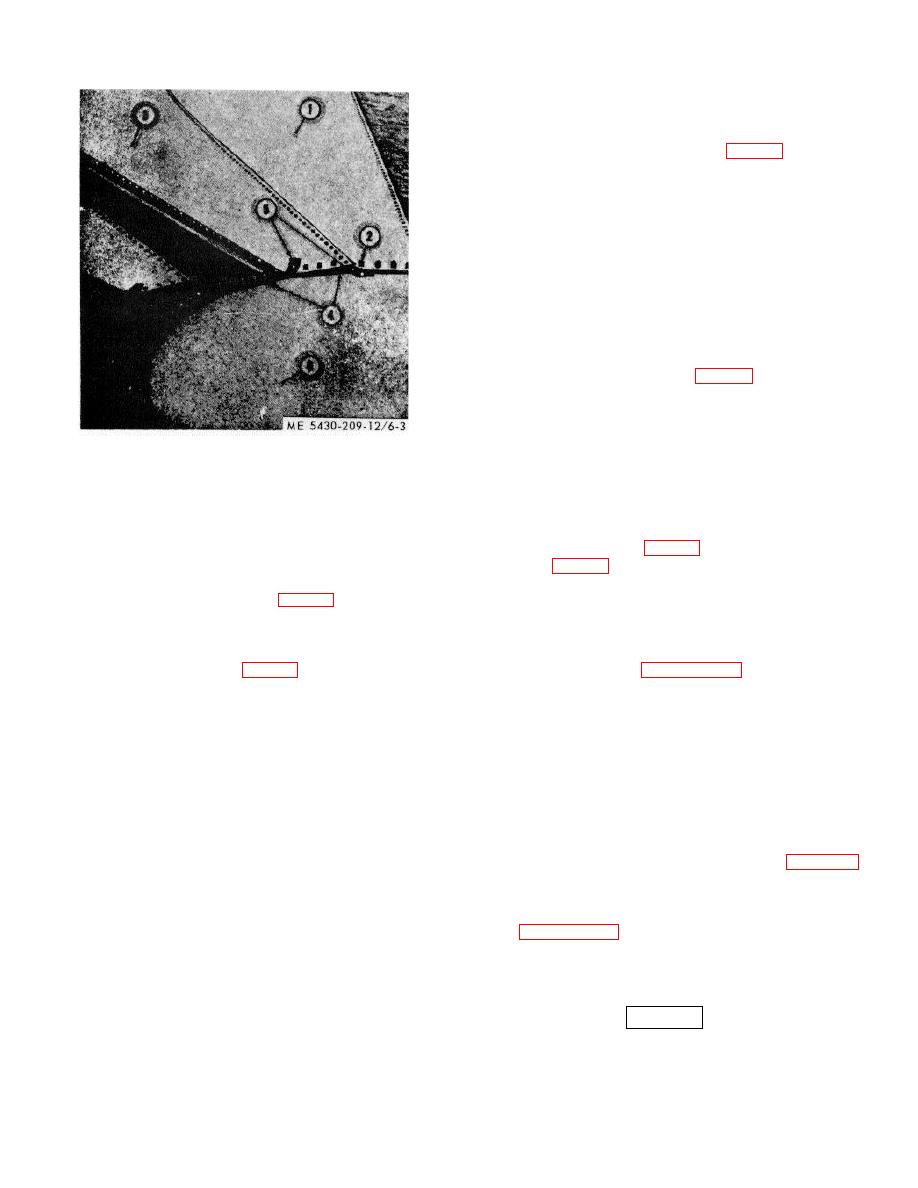

Figure 6-3. Installation of bottom plates |

|

||

| ||||||||||

|

|

TM 5-5430-209-12

each channel as bottom plates are installed on the center

support base.

b. First Plate.

(1) Place small end of plate (1, fig. 6-3) over

center column base bolts (2).

(2) Place a steel recessed washer, cupped side

down, over each bolt and install a nut loosely on each bolt.

NOTE

Do not tighten nuts on bolts until all bottom plates

have been installed.

c. First Intermediate Plate.

NOTE

Wedge gaskets must be used wherever three

plates are joined together.

(1) Place wedge gasket (4, fig. 6-3) over strip

gasket (5) at right edge of first plate.

NOTE

Use 1/2 by 11/2 inch bolts wherever three plates

1.

FIRST BOTTOM PLATE

are joined together.

2.

BOLT

3.

FIRST INTERMEDIATE PLATE

(2) Face small end of plate. Install this plate to left

4.

WEDGE GASKET

of first plate, or in a counterclockwise direction, around the

5.

STRIP GASKET

tank foundation.

6.

CENTER SUPPORT BASE

(3) Place small end of plate over bolts (2) with right

lap seam laid over bolts (3, fig. 6-2) in the left lap seam of

Figure 6-3. Installation of bottom plates.

first plate (1, fig. 6-3).

(4) Install steel recessed washer and nut on each

(3) Place bolt channel (4, fig. 6-2) under the

bolt along the lap seam and on the center base bolts as

right and left lap seams of the plate. These channels

described in b (2) above.

d. Remaining Intermediate Plates. Install remaining

line up with and about the inner ends, of the 24-hole

channels (2). Insert bolts (3) through all bolt holes.

intermediate plates as described in c above.

(4) Install gasket (5, fig. 6-3) along the full

length of the right and left lap seams. Allow a 1 1/2 -

last plate.

bolthole overlap at each end.

6-4. Tightening Tank Bottom

NOTE

When there is a break in the gasket material,

Start at small end of bottom plates and work toward large

the ends should overlap 2 boltholes and be cut

end, tightening nuts evenly in each lap seam. Avoid

squarely across the second hole. Sealing

crushing the gaskets. Tighten nuts to a maximum of 40 to

compound must be applied to each end of the

50 foot-pounds of torque.

overlap strip to insure a leakproof joint.

6-5. Bolt Replacement Plug

(5) Upon completion of the assembly, move this

If threads are stripped on one or more bolts, drive out bolt

plate to its approximate installation position on the tank

and use a bolt replacement plug as instructed in paragraph

foundation.

3-4.

d. Assembling Intermediate Bottom Plates. There

6-6. Testing Seams for Leakage

are eighteen intermediate plates assembled with

channels and strip gaskets. Except that channels are

Refer to paragraph 3-5 and test tank bottom seams for

placed under right lap seams only, follow assembly

leakage utilizing the vacuum seam tester provided with the

procedures outlined in c above. These procedures do

storage tank erection outfit.

not apply to the last bottom plate, since no further

assemblies are made on it. Keep the last bottom plate

6-7. Sealing Seams

separated from all others until it is installed.

WARNING

If tank is to be used for water storage, do not

6-3. Installation of Bottom Plates

apply sealing compound to tank bottom.

a. General. With the first bottom plate in its

Sweep bottom of tank clean after testing seams. With

approximate position, lay the remaining plates around

bottom dry, apply sealing compound to all bolts and seams.

the tank foundation. Place bolt retaining boards under

6-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |