|

|||

|

|

|||

|

Page Title:

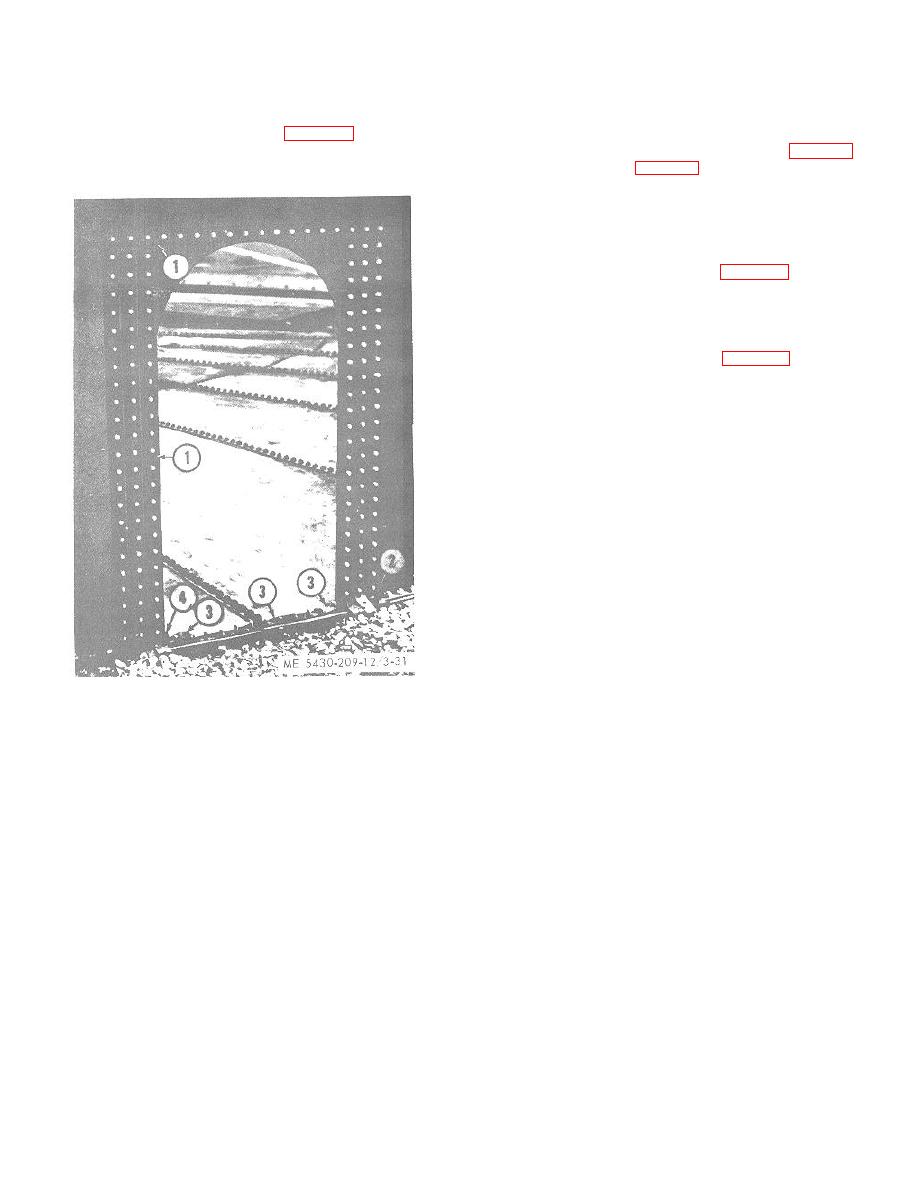

Figure 3-31. Gaskets at cleanout opening installed (10,000 barrel capacity tank). |

|

||

| ||||||||||

|

|

TM 5-5430-209-12

Side channels.

(2)

(b) Insert retaining channel (4) through clips on the

bolt channel (1).

NOTE

(c) Install a strip gasket (1, fig. 3-31) along full

The 100-, 250-, and 500-barrel tanks contain

length of top seam outside the stave. Allow a 1bolthole

one vertical row of channels (5 and 6, fig. 3-30)

overlap at each end.

and boltholes (fig. 3-31) on each side seam, the

1000and 3000-barrel tanks contain two vertical

rows of channels and boltholes on each side

seam, and the 10,000-barrel tank contains three

vertical rows of channels and boltholes on each

side seam.

(a) Place bolt channel (5, fig. 3-30) inside the

tank on each row of boltholes. Insert bolts (3) through all

boltholes.

(b) Insert retaining channel (6) through clips

on bolt channel (5) to retain the bolts.

(c)

Install strip gasket (1, fig. 3-31) along the

full length of each row of bolts. Pass gaskets under top

seam gasket.

(d) Apply sealing compound at overlap of top

and vertical seam gaskets.

(e) Install radii gaskets (2 and 4) under

vertical seam gaskets at bottom chime of stave.

(f)

Install wedge gaskets (3) at each side of

opening at offset formed by the chime with the bottom

sections.

(g) Recheck wedge gasket at lap formed by the

adjoining bottom sections at center of cleanout opening.

3-26. Water Test

a. Tank Bottom. There are two methods of testing

the bottom for leakage. Both methods require use of a

temporary partial cover on the cleanout opening.

(1) Fabricate a temporary partial cover (fig.

332) for the cleanout opening. Cover must form a liquid-

tight seal over the lower 10 inches of the cleanout

opening.

1.

STRIP GASKET

2.

RADII GASKET

3.

WEDGE GASKET

4.

RADII GASKET

Figure 3-31. Gaskets at cleanout opening installed

(10.000 barrel capacity tank).

3-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |