|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

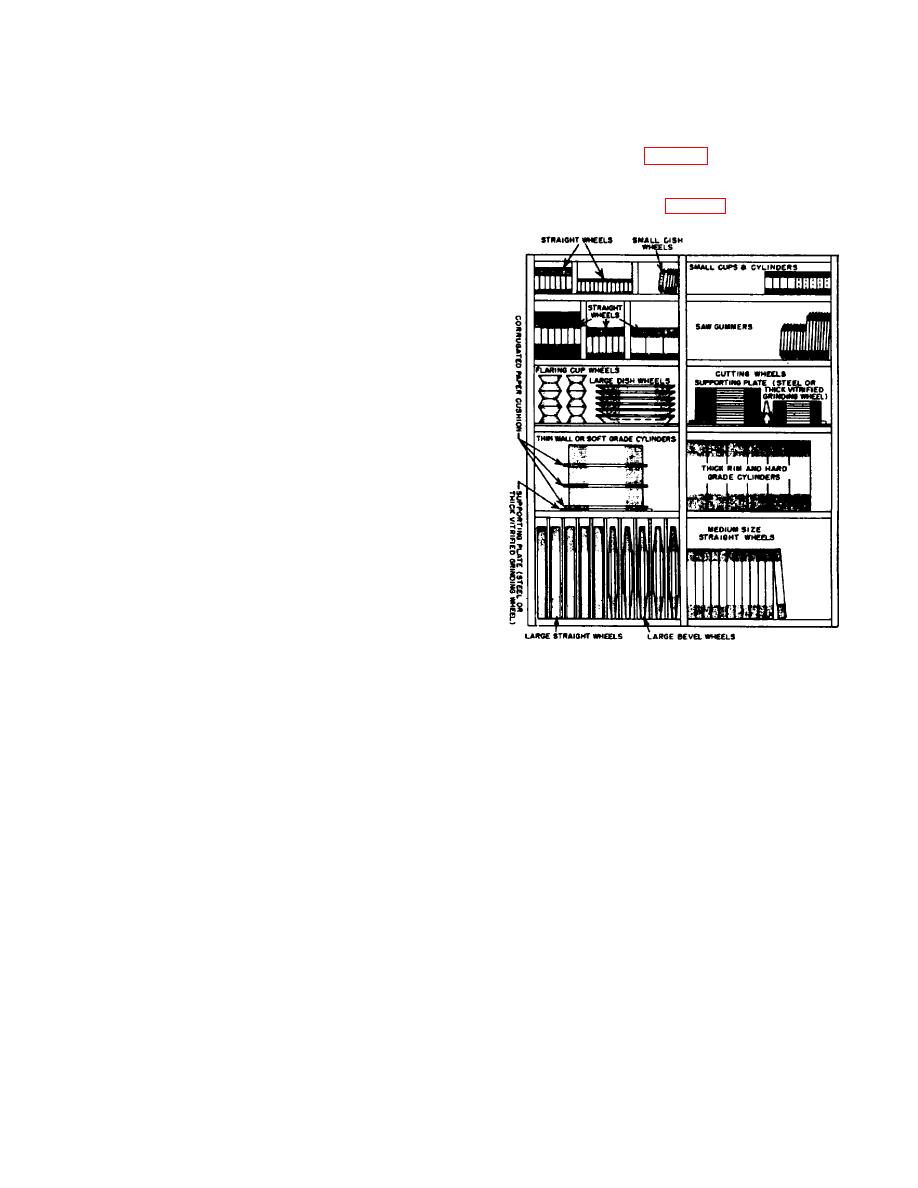

should be built to accommodate wheels of various sizes.

(b) Used serviceable tubes should be

Separate sections of storage racks should be

completely deflated by removing the valve core. They

constructed within standard shelving to prevent the

can be folded and stored.

wheels from rolling off (fig 5-46). Wheels of the same

(c) Tubes will be placed in storage

size, type, and specification should be stored together

grouped according to size and type. Removal from

and should be arranged, so far as possible, to facilitate

storage will be on the basis of oldest stock first.

issue on the basis of FIFO (fig 5-47).

(d) Self-sealing tubes must be inflated

enough to retain full molded size. Storage aids (e.g.,

pallet support sets) will be used to assure retention of

shape and size.

d. Solid rubber tires and track components. Solid

rubber tires, rubber components of combat vehicle

track, track support rollers, and track idler wheels will be

protected as outlined in c above.

e. Rubber cements. Rubber cements must be kept

within 32 . to 90 . and all containers must be kept

F

F

tightly closed at all times. Rubber cements, dependent

upon flash point, are either flammable liquids or

combustible liquids and must be considered for storage

in light of their flammability properties.

5-36.

Abrasive or Grinding Wheels.

a. General. All grinding wheels are fragile and

should be handled and stored carefully to prevent

breakage and chipping.

b. Location. Wheels should be stored in covered,

dry areas, and should not be exposed to extreme

temperature changes. Escaping steam and rain will

seriously affect grinding wheels; consequently, such

Figure 5-46. Bin storage of grinding wheels.

wheels should be away from radiators and open

windows.

c. Storage. Generally, grinding wheels are stored

in bins and racks. Smaller sizes are often carried in bin

drawers. The bins, racks, or drawers

5-84

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |