|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 38-400/NAVSUP PUB 572/AFMAN 23-210 MCO 4450.14/DLAM 4145.12

(2)

Although

set

rules

cannot

be

established for allocation of space to working areas, it is

essential to keep such space to a minimum. Working

areas must be controlled to ensure that such areas do

not expand beyond the defined boundaries.

(a) Temporary storage of materials

within a working area, particularly in receiving and

shipping bays, should be held to a minimum Receipt

and processing operations should be organized so that

materials can be processed immediately and removed

to their storage locations.

(b) Utilization of cube in working areas

is just as important as in storage space. The use of

pallet racks and shelving frequently will save space in

working areas.

(c) When practical, working areas

should be consolidated.

For example, creating a

centralized packing operations for several buildings will

result in less space consumption than a separate

operation in each of the buildings. Also, this facilitates

the centralized use of special equipment and

concentrates the supervision of specialized jobs.

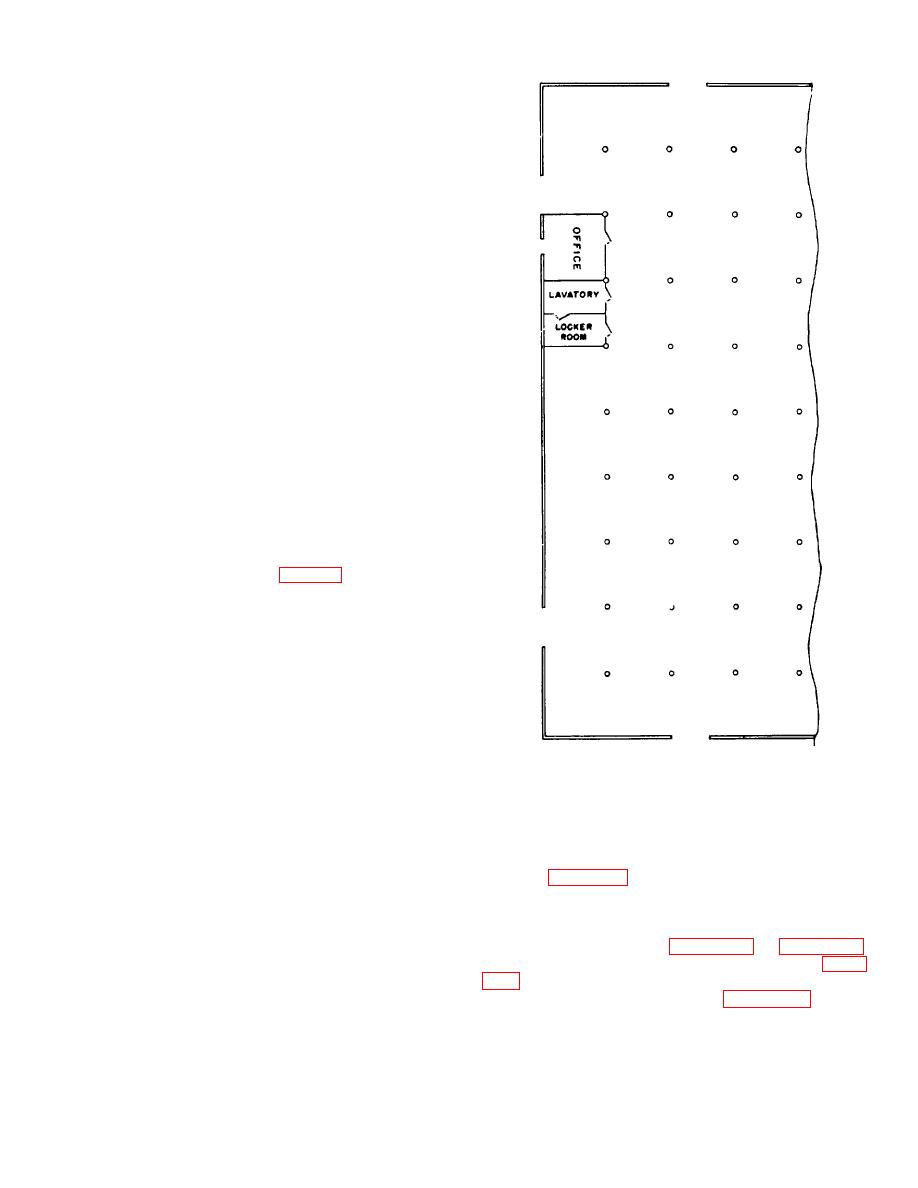

2-10. Preparation of Layout Plan.

When making storage layouts, whether for covered or

open storage, a floor plan for each storage area should

be prepared. The plan must indicate all obstacles such

as support columns, stairwells, elevator shafts, office

locker rooms, and rest rooms (see fig 2-28).

Figure 2-28. Storage Floor Prior to Stock Layout

a. Basic bulk storage layout criteria. Most of the

principles involved in bulk storage are exemplified in the

layout for a complete building as illustrated by figures 2-

29 and 2-30. Various layouts for bulk storage are

shown. There is practically no variation in bay depth as

shown in figure 2-29; each bay is about 40 feet in depth,

thus, a lot of less-than-carload quantity will not

completely fill a bay and, therefore, results in loss of

space. The main aisle runs lengthwise through the

building. When comparing figure 2-29 with figure 2-30,

note that the aisle layout is unchanged, but that in figure

of bay sizes are provided. Also, in figure 2-30, side-to-

back bays of various

2-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |