|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM

9-2350-238-20-2

2-27.

CLEANING

(CONT).

Do not use solvent to clean rubber parts. Clean rubber parts by washing with mild solution

5

of soap and water.

Dry

parts

by

blowing

with

low-pressure

compressed

air

or

wiping

with

clean,

lint-free

cloths

6

(item 8, appx C).

7

should

be

cleaned

by

procedures

in

TM

9-214.

8

Spot paint metal surfaces after repairs, as required. Sand damaged areas, clean with sol-

vent, and rinse with water. Surface must be clean and dry. Paint with CARC to match ex-

isting color, refer to TM 43-0139.

2 - 2 8 . L U B R I C A T I O N . Keep a light coat of lubricating oil (CLP) (item 5, appx C) on parts during repair

procedures to prevent rusting. Lubricate parts during repair and assembly as required. Refer to page 2-8.

2-29.

PAINTING

I N S T R U C T I O N S . Complete painting is authorized for and done by general

support maintenance personnel or higher. Spot painting and restenciling vehicle markings is

done

by unit maintenance personnel. Instructions for material preparation, priming, and finish are

given in TM 43-0139.

2-30.

NONSKID

AREAS.

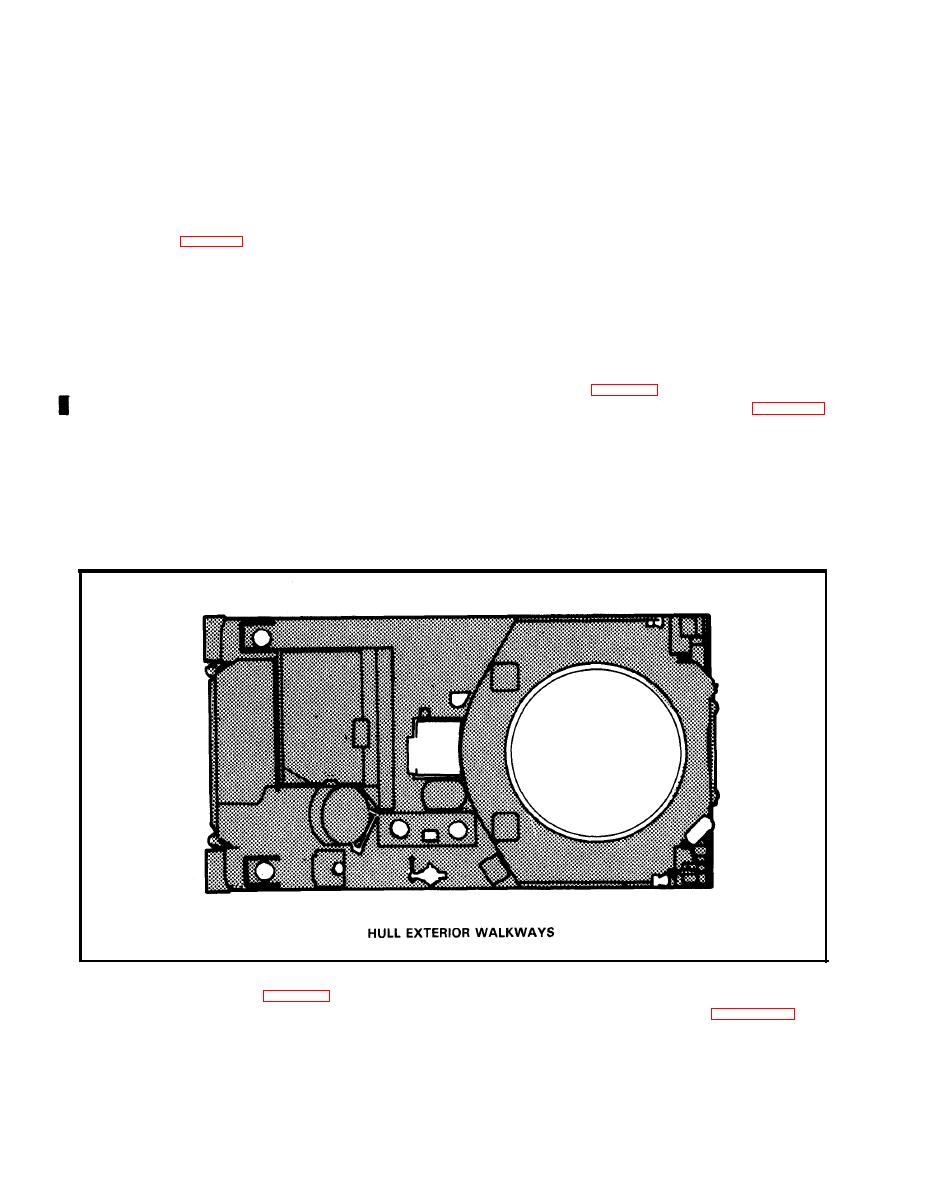

Nonslip paint (item 15, appx C) will be used to coat deck areas where personnel walk. The areas

to be coated with nonslip paint are shown shaded in the above illustration and on page 2-77.

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |