|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2350-238-20-1

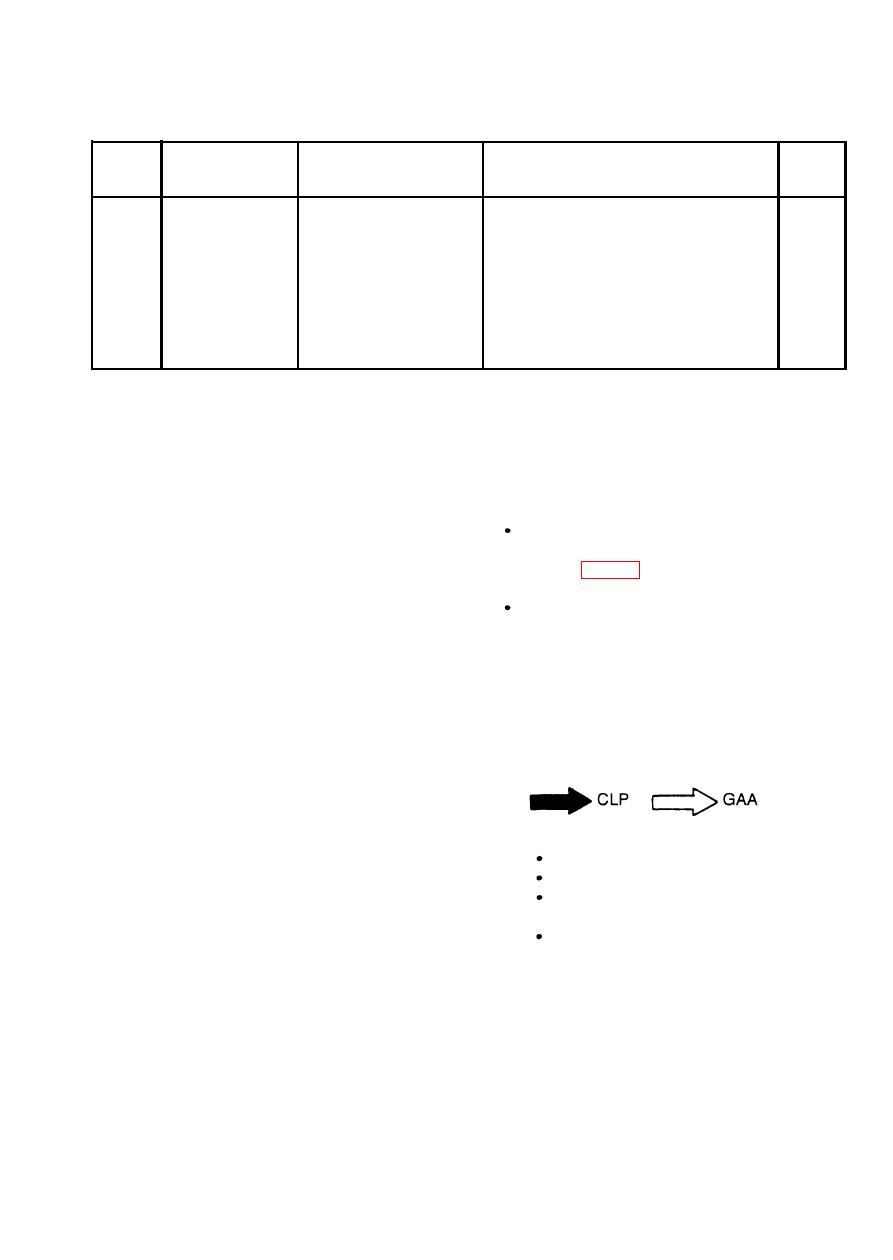

MANDATORY REPLACEMENT PARTS

Item

National Stock

Part Number

Number

No.

Nomenclature

Qty

Semiannually

1

5571024

2

Filter adapter nonmetallic washer

2

MS35802-3

2

Fluid pressure filter element

MS35338-46

3

5310-00-637-9541

9

Lockwasher

4

7374386

5330-00-599-2180

1

Preformed packing

10908813

5

5330-00-991-8401

Transmission oil filter element

2

2940-00-740-3108

6

5703114

1

(Part of fluid pressure parts kit)

valve and check escaping grease for contami-

d. Lubrication. The lubrication procedures

nation. If contamination is found, replace the

identified in the PMCS table are for unit mainte-

grease.

nance. Lubrication intervals (on-condition or

hard time) are based on normal operation.

NOTE

Lubricate more often during constant use or in

severe conditions.

If no other treatment is directed, coat

unprotected metal surfaces with CLP

(item 8, appx C) after cleaning.

fied in the lubricant table.

Clean around filler necks/drain

(2) Hydraulic samples must be taken

plugs/openings before servicing to

annually by all units. All samples are sent to

keep dirt from entering system.

Army Oil Analysis Program (AOAP) laboratory

as prescribed by TB 43-0210 and DA PAM 738-

(8) Perform a semiannual lubrication as

750. No other systems are subject to AOAP.

soon as possible after water fording operation.

(3) Dispose of used lubricants in accor-

dance with local Standing Operating Proce-

are identified by arrow as follows:

dures (SOP).

(4) For arctic operation, see FM 9-207.

(10) Observe the following:

(5) For desert operation, see FM 90-3.

Never use wrong type of grease.

Never use too much lubrication.

(6) Clean all grease fittings before attach-

Always clean grease fittings before

ing grease gun.

lubrication.

Always use the Lubrication instruc-

(7) When using grease gun, operate until

tions.

grease appears around seals or out of relief

2-17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |