|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

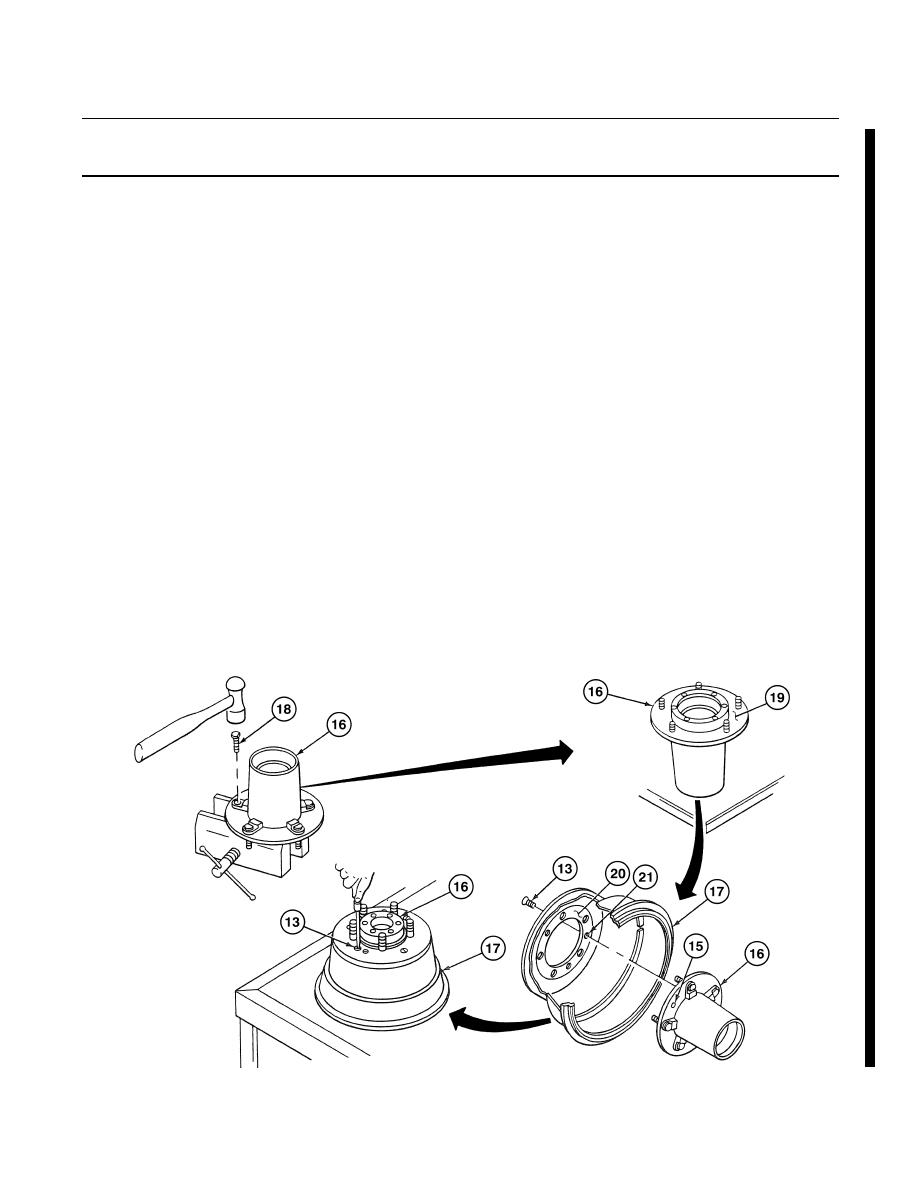

TM 9-2330-202-14&P

4-43.1. HUB, BRAKEDRUM, AND WHEEL BEARINGS MAINTENANCE (M101A1 AND

M116A1) (CONTINUED).

3.

Wipe spindle clean with drycleaning solvent and rag. Inspect spindle for cracks, bends, and scored

or discolored bearing surfaces. If threads are damaged, restore. Notify Direct Support maintenance if

spindle is damaged beyond repair.

4.

Inspect wheel hub for cracks, breaks, and burrs. Remove burrs with abrasive cloth. Replace wheel

hub if damaged.

5.

Inspect brakedrum for cracks, scoring, pitting, and grooves. Notify Direct Support maintenance if

brakedrum is damaged.

6.

Inspect all remaining components for damage. Replace if damaged.

d.

ASSEMBLY

NOTE

Use left shoulder bolts on left wheel hub and right shoulder bolts on right wheel

hub.

Align flat on shoulder bolt with flat on wheel hub flange.

1.

If removed, drive five shoulder bolts (18) into wheel hub (16).

2.

Coat mating surface (19) of wheel hub (16) and mating surface (20) of brakedrum (17) with clean oil.

3.

Align countersunk holes (21) in brakedrum (17) with tapped holes (15) in wheel hub (16).

NOTE

Do not tighten screws at this time.

4.

Install three screws (13) loosely.

5.

Using soft-face mallet, tap brakedrum (17) against wheel hub (16).

6.

Tighten three screws (13).

438-007

Change 2 4-90.3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |