|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-202-14&P

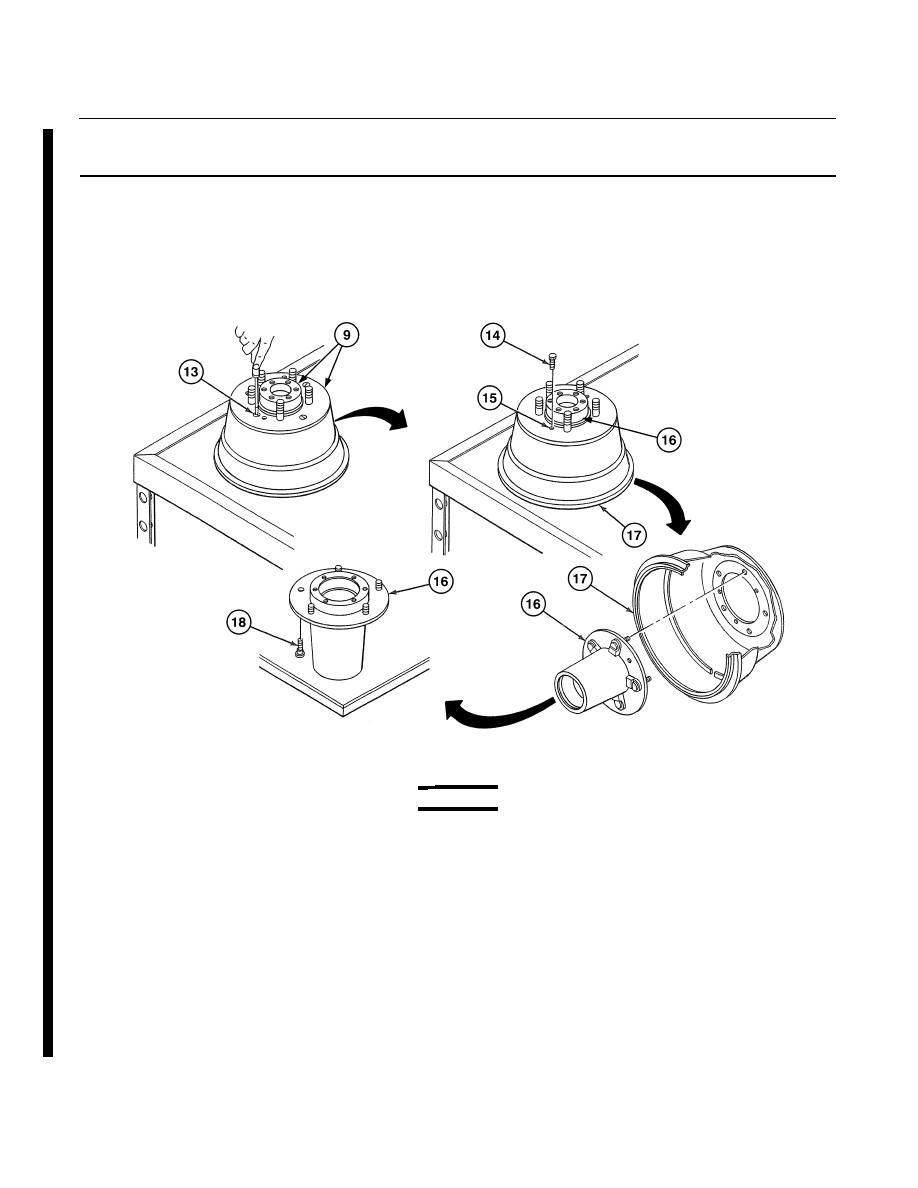

4-43.1. HUB, BRAKEDRUM, AND WHEEL BEARINGS MAINTENANCE (M101A1 AND

M116A1) (CONTINUED).

2.

Place wheel hub and brakedrum assembly (9) on work bench.

3.

Remove three screws (13).

4.

Screw three retaining cap screws (14) evenly into tapped holes (15) to drive out wheel hub (16) from

brakedrum (17).

5.

Place wheel hub (16) on work bench. If damaged, drive out five shoulder bolts (18) and discard.

438-006

c.

CLEANING AND INSPECTION

WARNING

Wear an approved filter mask and gloves. NEVER use compressed air or a dry

brush to clean brake components. Dust may be removed using an industrial-

type vacuum cleaner. Clean dust or mud away from brake components with

water and a wet, soft brush or cloth. Failure to follow this warning may result in

serious illness or death to personnel.

Drycleaning solvent P-D-680 is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open

flame or excessive heat.

1.

Clean and inspect inner and outer bearing hub cones and rollers in accordance with

TM 9-214. If any cone or roller needs replacing, all cones and rollers must be replaced.

2.

Clean all other removed components with drycleaning solvent and rag and allow to dry.

4-90.2 Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |