|

|||

|

|

|||

|

Page Title:

HYDRAULIC BRAKE ACTUATOR ASSEMBLY REPLACEMENT (continued) |

|

||

| ||||||||||

|

|

TM 9-2330-202-14&P

4-38.

HYDRAULIC BRAKE ACTUATOR ASSEMBLY REPLACEMENT (continued).

NOTE

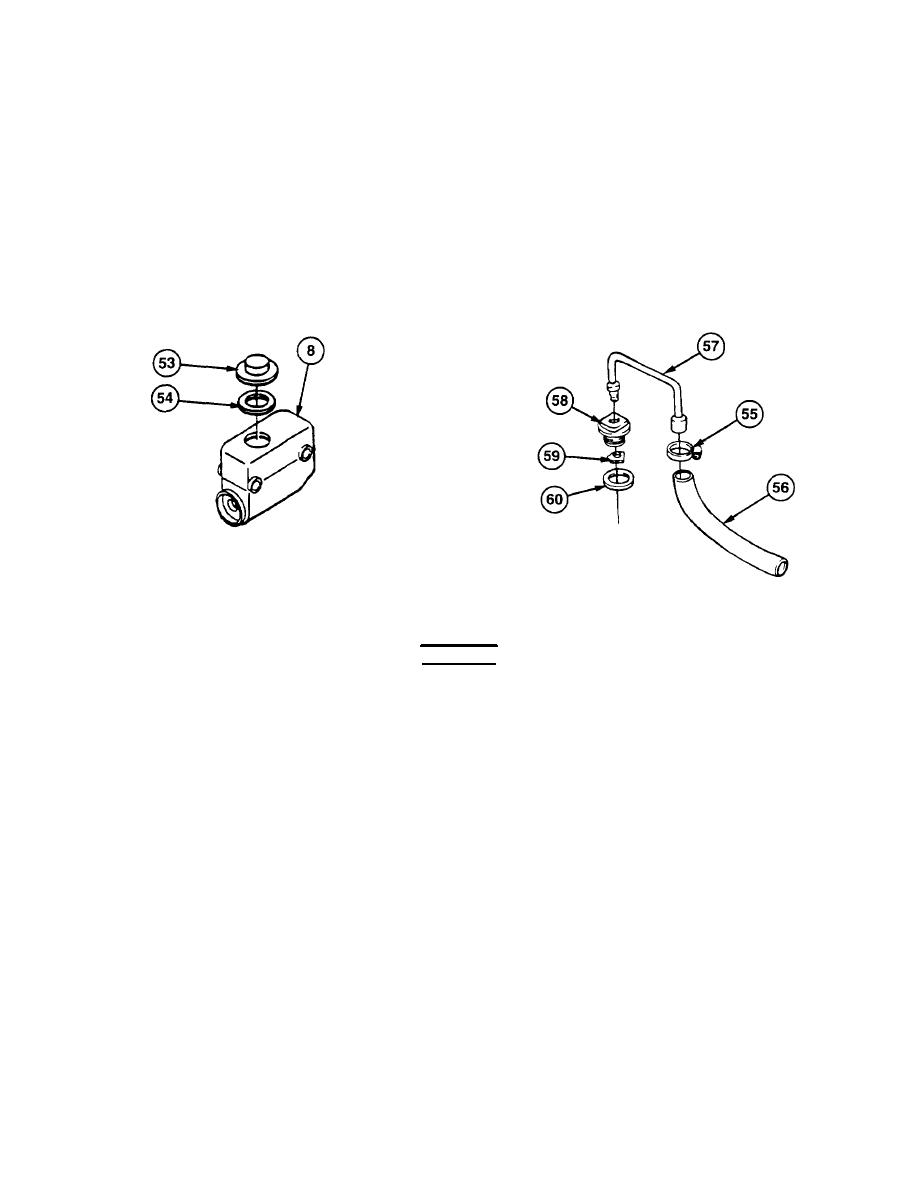

For trailers with master cylinder cap, do step 8. For trailers with drain hose, do steps 9 and 10.

8.

Remove cap (53) and gasket (54) from master cylinder (8). Discard gasket if damaged.

9.

Loosen clamp (55) and remove drain hose (56) from vent tube (57).

10. Remove vent tube (57), filler cap (58), baffle (59), and gasket (60) from master cylinder (8). Discard gasket if

damaged.

c.

CLEANING AND INSPECTION

WARNING

Drycleaning solvent P-D-680 is toxic and flammable. Always wear protective goggles and

gloves, and use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and

DO NOT breathe vapors. DO NOT use near open flame or excessive heat.

1.

Clean all removed components with drycleaning solvent and rag and allow to dry. Clean boot with detergent and

water.

2.

Inspect all removed components for wear, breaks, cracks, damaged welds, corrosion, or other damage. Replace if

damaged.

3.

Inspect breakaway lever for worn ratchet teeth. Replace if damaged.

4.

Remove any corrosion with a wire brush.

5.

Inspect for a worn slot in pushrod. Replace pushrod if slot is worn.

6.

Inspect for a weak or broken spring. Replace if damaged.

7.

Inspect shock absorber for leaks or bad rubber bushings. Replace if damaged.

8.

Inspect master cylinder for leaks. Replace if damaged.

4-67

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |