|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-202-14&P

4-37.

WHEEL CYLINDER REPLACEMENT (continued).

b.

CLEANING AND INSPECTION

WARNING

Drycleaning solvent P-D-680 is toxic and flammable. Always wear protective goggles and gloves,

and use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO NOT

breathe vapors. DO NOT use near open flame or excessive heat.

1.

Clean all removed components, except wheel cylinder, with drycleaning solvent and rag and allow to dry. Wipe wheel

cylinder with a clean rag.

2.

Inspect components for cracks, breaks, corrosi on, or damaged threads. Replace if damaged.

c.

INSTALLATION

1.

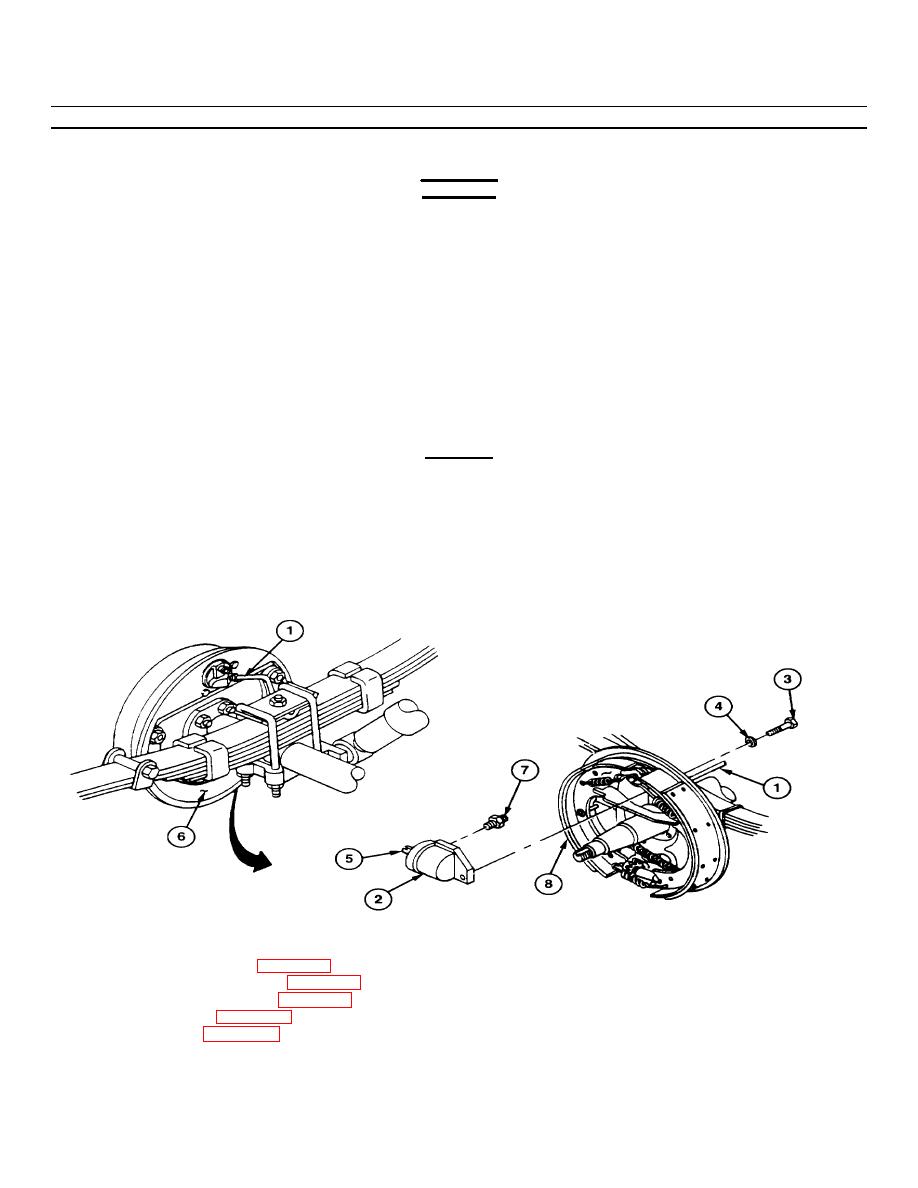

If removed, install bleeder valve (7) on wheel cylinder (2).

CAUTION

Make sure boot of wheel cylinder is dry before installing wheel cylinder. Failure to follow this

caution may cause brake fluid to damage brakeshoe linings.

2.

Assemble wheel cylinder (2) and link (5) at backing plate (6), with link engaged in primary brakeshoe (8). Install new

lockwasher (4) and bolt (3) on wheel cylinder (2). Torque bolt between 130 and 280 lb-in (15-26 Nom).

3.

Connect hydraulic brake tube assembly (1) to inlet of wheel cylinder (2).

FOLLOW-ON TASKS:

Install hub and brakedrum (para 4-43).

Install wheel and tire assembly (para 4-44).

Bleed hydraulic brake system (para 4-41).

Adjust service brake (para 4-36).

Adjust handbrakes (para 4-34).

4-62

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |