|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-285-24-1

2-33.

HORN SYSTEM MAINTENANCE

a.

Horn and Relay (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION

4

a. Electrical

Inspect

Replace if cracked, broken,

leads

frayed, defective, or

(5 thru 7)

otherwise damaged. Polish

and horn (17)

corroded terminals to

brightness with fine

sandpaper

b. Relay (8)

Inspect

Replace if cracked, broken,

defective, or terminals

damaged

c.

All other parts

Inspect

Replace if cracked, broken,

distorted, or threads

damaged

ADJUSTMENT

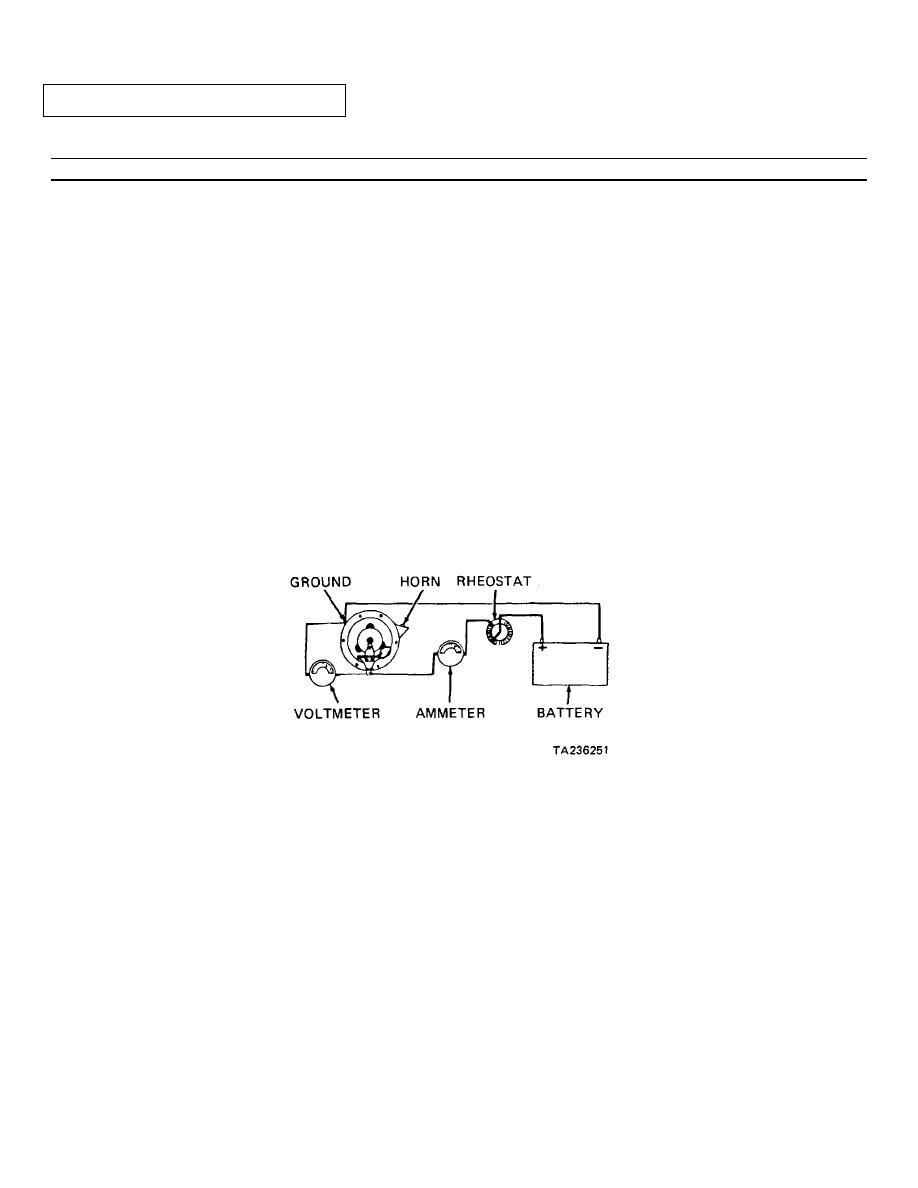

5

a. Horn (17)

Connect

Connect horn to adjustment

circuit as shown. Adjust

rheostat for 12.4 Vdc

indication on voltmeter

NOTE

Do not stuff rags or other material in horn throat to muffle sound while adjusting. This

changes vibration frequency and results in a false current setting.

b. Adjusting screw

Turn

Turn adjusting screw 1/10

turn at a time, until

ammeter indicates 4.5

amperes. Turn adjusting

screw counterclockwise to

increase current, clockwise

to decrease current; then

disconnect horn from test

circuit

2-369

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |