|

|||

|

|

|||

|

Page Title:

PREVENTIVE MAINTENANCE CHECKS AND SERVICES - CONTINUED |

|

||

| ||||||||||

|

|

TM9-2320-270-20-1

PREVENTIVE MAINTENANCE CHECKS AND SERVICES - CONTINUED

A ANNUALLY

S SEMIANNUALLY

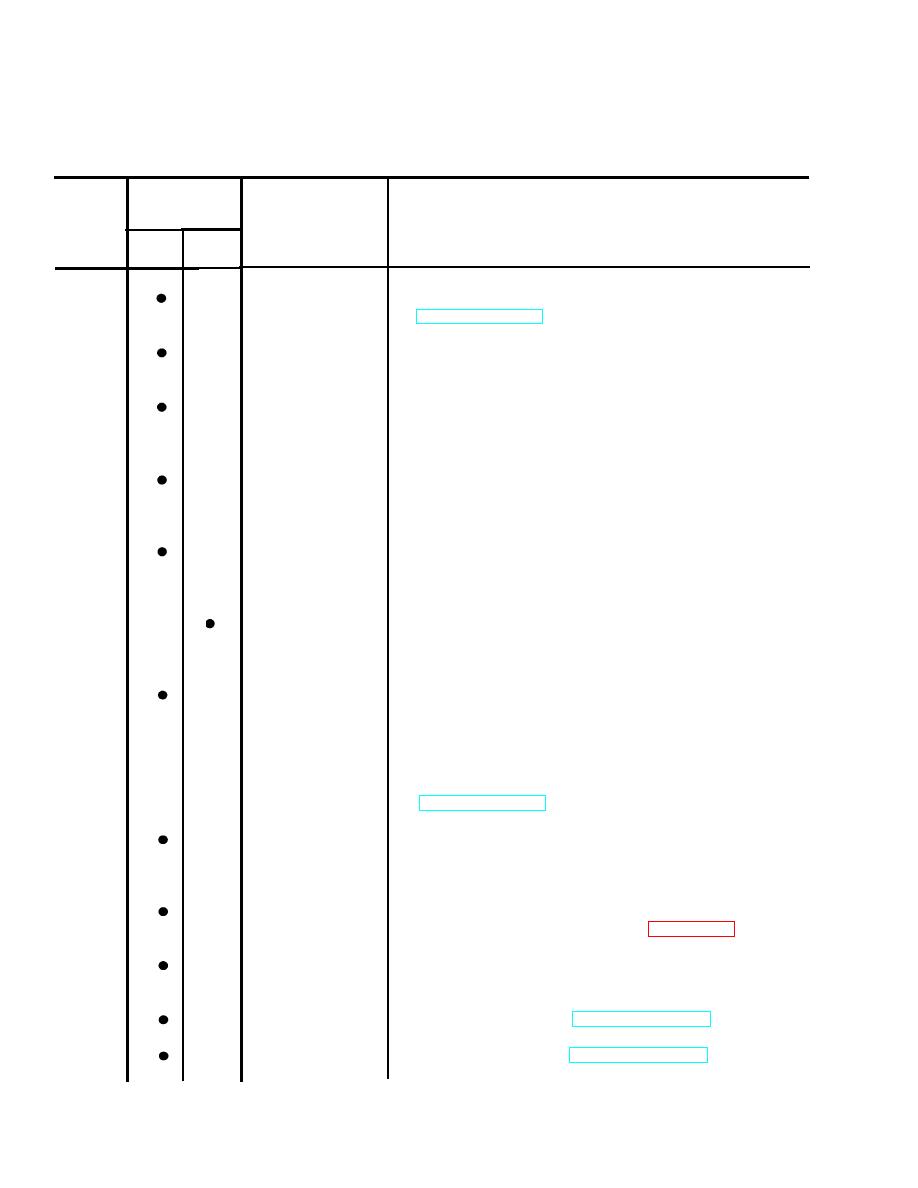

ITEM

INTERVAL

TO BE

ITEM

PROCEDURE

INSPECTED

A

S

NO.

c. Lubricate brake camshaft/slack adjuster

(LO 9-2320-270-12).

a. Inspect all brake valves for leaks or damage.

Brake Valves

27

Replace damaged or leaking valves (page 4-609).

b. Apply brakes and listen for immediate ex-

hausting of air. If air does not exhaust immedi-

ately, replace relay valve (page 4-785).

c. Drain air in one tank and observe air pres-

sure gage. If both systems lose air pressure,

replace doublecheck valve (page 4-796).

Inspect air reservoirs and air lines for damage

Air Reservoirs

28

and leakage. Replace damaged or leaking parts

and Air Lines

(page 4-609).

Inspect cab mounts for secureness and damage.

Cab Mounts

29

Tighten loose cab mounts. If cab mounts are dam-

aged, notify Direct Support Maintenance.

Inspect all propeller shafts and U-joints for dam-

Propeller

30

age and security. There should not be any movement

Shafts and

between propeller shaft and U-joints in any direc-

U-Joints

tion. If there is movement between propeller shaft

and U-joints, replace damaged U-joints. Tighten

loose flange bolts and nuts (page 4-574). Lubricate

(LO 9-2320-270-12).

a. Inspect main transmission for leaks. If

Main

31

main transmission is leaking, notify Direct Support

Transmission

Maintenance.

b. Inspect temperature sending unit and wire for

damage. Replace damaged parts (page 4-398).

c. Check linkage for proper operation. If

linkage requires adjustment, adjust (page 4-525).

d. Clean breather (LO 9-2320-270-12).

e. Change filters (LO 9-2320-270-12) (pages

4-562 and 4-563).

2-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |