|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-269-34-1

CRANKSHAFT AND MAIN BEARINGS - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

INSTALLATION

NOTE

During inspection, the crankshaft and bearing shells may have appeared to be satisfactory for

installation. In the following steps, measurements will be taken to assure that the parts are within

limits and may be found to be defective. If new bearing shells are installed and tolerances are not

met the crankshaft will be replaced.

When installing new crankshaft, use all new bearing shells and thrust flanges, bearing shells used

in this engine are select fit and require no line reaming. When re-installing used crankshaft and

bearing shells, install old shells in the same locations from which they were removed.

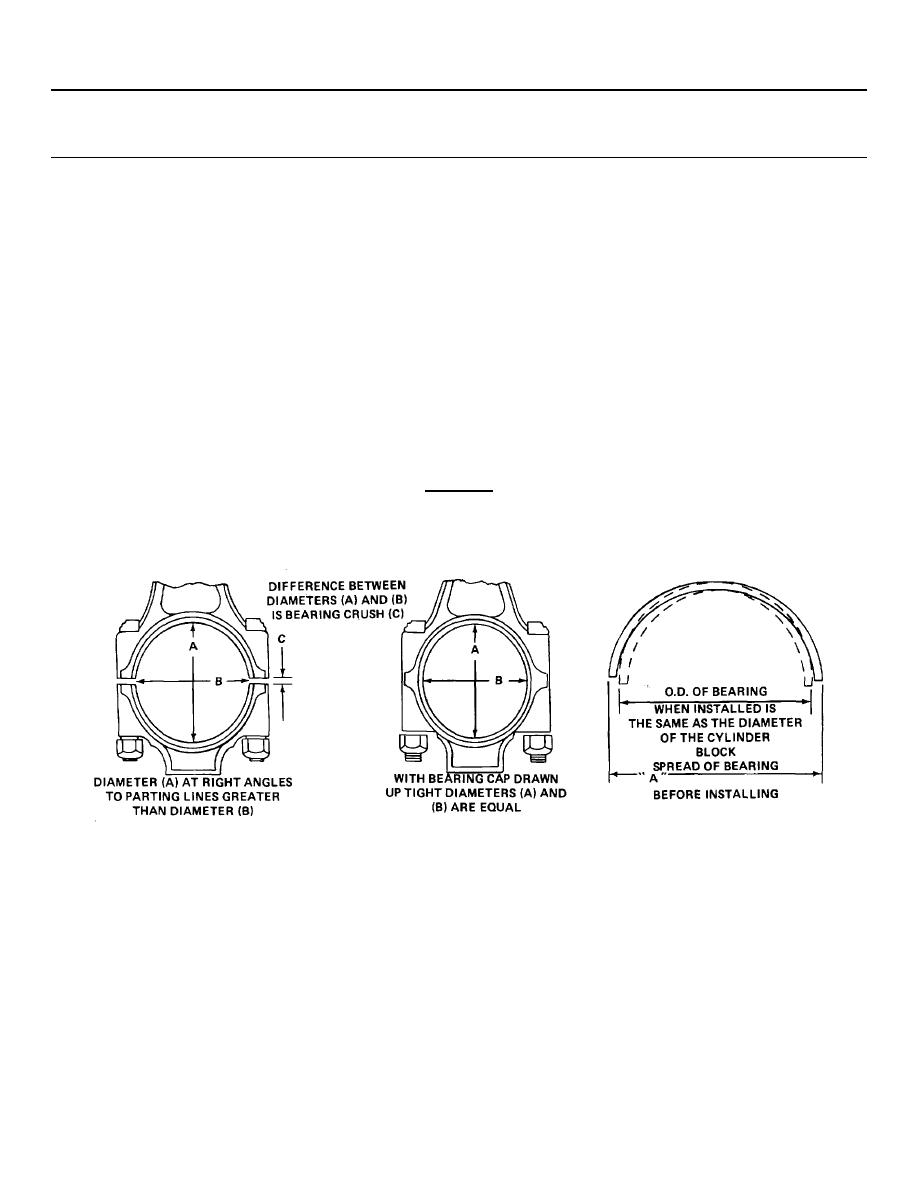

It is important that bearing shells fit tightly. The bearing manufacturer makes the diameter at right

angles to the parting line slightly larger than the actual diameter of the bore into which they are

assembled. When the assembly is drawn tight, bearings are compressed, assuring a positive

contact between bearing back and the bore. The increased diameter is called bearing crush.

CAUTION

Do not file, lap, or otherwise rework the bearing caps or block in order to reduce clearance.

Reworking will result in out-of-round bores, shell distortion, and will destroy the bearing crush.

TA237984

2-122

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |