|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2320-269-34-1

CYLINDER BLOCK - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

CLEANING - CONTINUED

8.

Continued

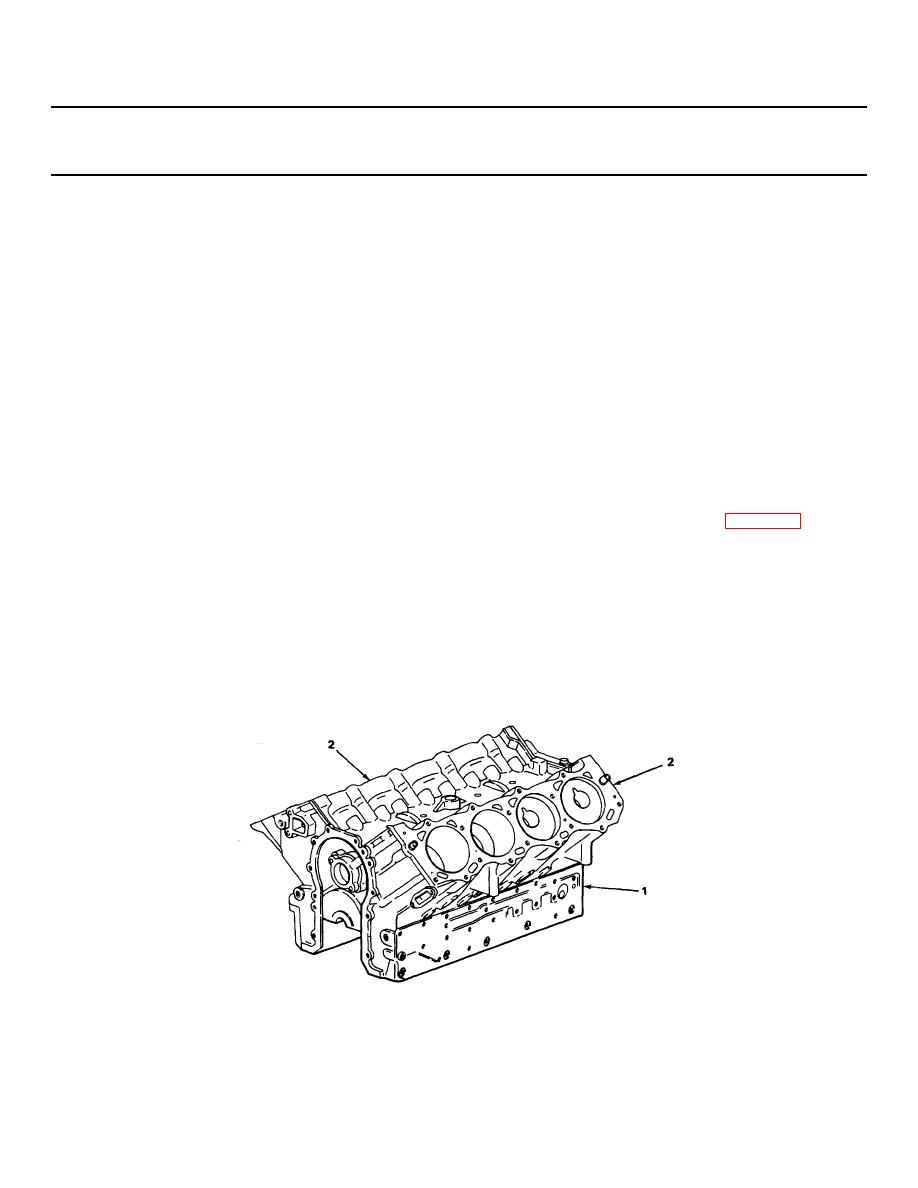

Cylinder block (1)

j.

Remove block from acid and allow to

drain.

k. Put block (1) back into acid for about 10

more minutes.

I. Repeat steps 8i and 8j until all scale is

removed.

m. Rinse block in clea n, hot water.

n. Neutralize the acid that may cling to the

casting by Immersing the block (1) in

an alkaline bath.

o. Steam clean block (1) to remove

alkaline solution.

p. Remove cables and hoist.

q. Dry block (1) with compressed air.

INSPECTION/REPLACEMENT

NOTE

For more information on how to Inspect parts, go to General Maintenance Instructions (page 2-46).

Replace damaged or defective parts as needed.

9.

Cylinder block (1)

Top machined

a.

Using machinist's rule and thick ness

surfaces (2)

gage, check for flatness.

Lengthwise the surface must not vary

more than 0.006 inch (0.152 mm).

Crosswise the surface must not vary

more than 0.003 inch (0.076 mm).

TA237966

2-95

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |