|

|||

|

|

|||

|

Page Title:

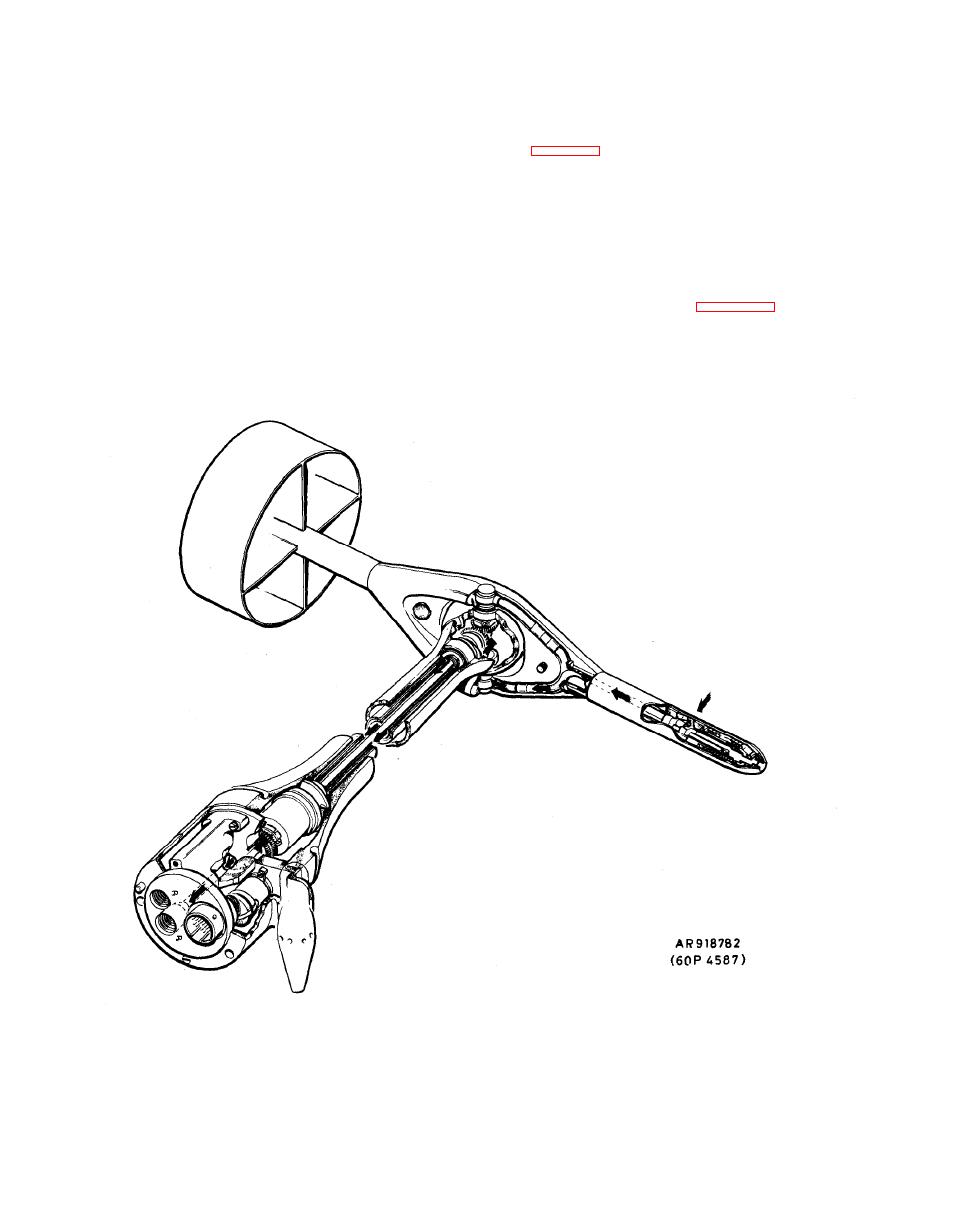

Figure 1-11. AADS Cutaway View showing Static Plumbing. |

|

||

| ||||||||||

|

|

TM 9-1270-219-13&P

(1) The pitot pressure is conveyed via a rolling

in

turbulent

airflow.

The

fins

and

shroud

of

the

flexible rubber tube in a hollow shaft along the axis of the

tail are built into the shaft from glass-reinforced polyester

neck. See figure 1-10. This pressure transmitting

to make a light and rugged structure.

t e c h n i q u e ensures that air leakage in the AADS pitot line

will not cause errors greater than 0.5 knots at the EPU

pressure transducer. This hollow shaft also transmits the

rotation of the gimbal in the AADS yaw axis to an angular

c. N e c k A s s e m b l y . The neck assembIy has a gimbal

resolver.

joint at its outboard end. The free side of the gimbal is a

(2) Static pressure enters the neck via the other stub

yoke in two halves which, when bolted together, holds the

axle and is transmitted by a second larger concentric

head and tail assemblies and incorporates two nylon stops

hollow shaft through the neck. See figure 1-11. This

w h i c h limit the gimbal travel to 120 in yaw. Pitot and

second shaft transmits gimbal rotation in the yaw axis to

static lines in the yoke are joined to those emerging from

the other angular resolver. The two rotations move the

the head at one end and to the gimbal stub axles at the

shafts of the angular resolvers mounted in the body to

other end.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |