|

|||

|

|

|||

|

Page Title:

Table 2-2. Troubleshooting--Continued |

|

||

| ||||||||||

|

|

TM 9-1240-311-34

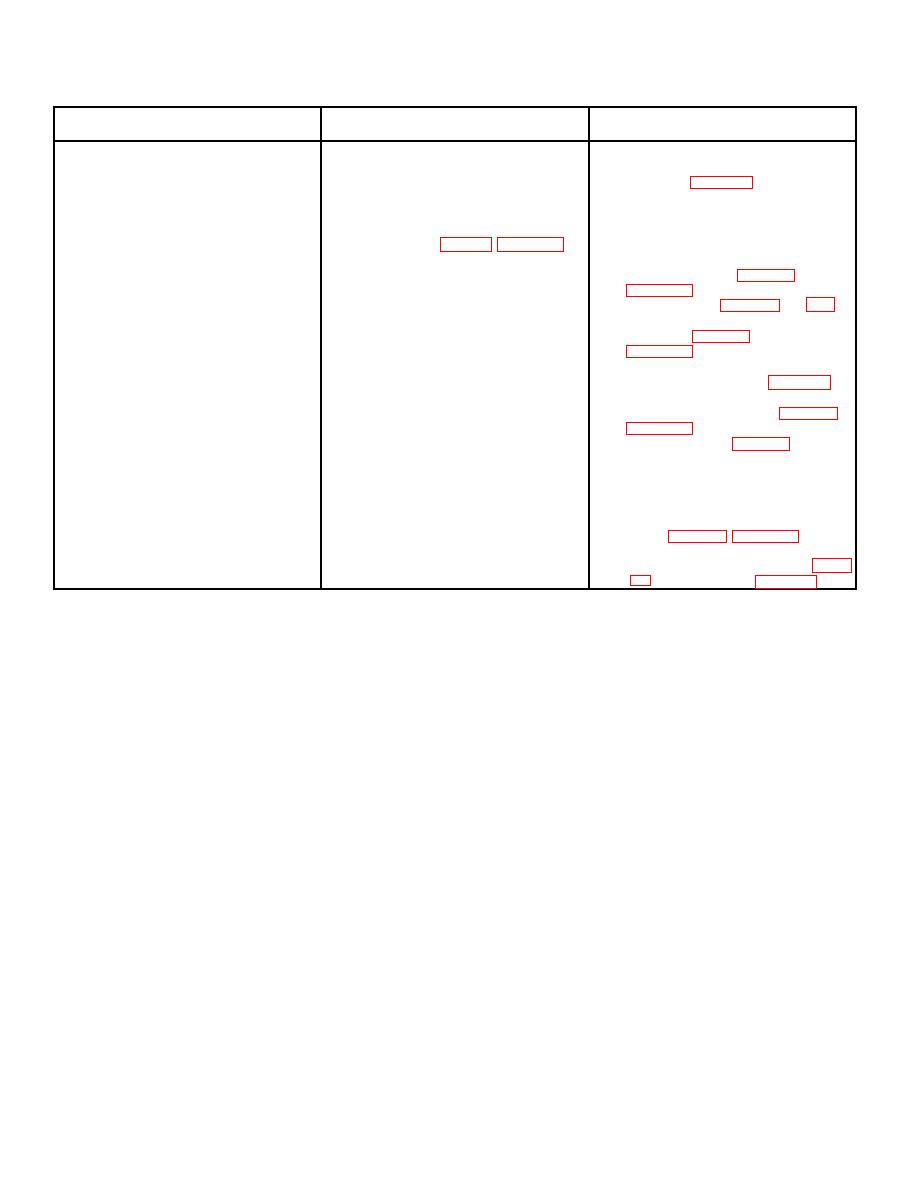

Table 2-2. Troubleshooting--Continued

Malfunction

Probable Cause

Corrective Action

a. Dirt on entrance or exit optics.

a. Clean surfaces of optics.

Image not clear or out of focus.

b. Diopter knob not adjusted to cover

b. Adjust knob. Para 3-7a and g.

a minimum span of +4.00 to

-4.00 diopters.

a. Defective contact or loose wire.

a. Check wire connection or replace

Reticle lamps fail to illuminate.

contact (9, fig. 3-6). Para 3-10.

b. Lack of electrical power to reticle

b. Check electrical input into recep-

projector.

tacle assembly (9, fig. 3-11).

c. Lamps burned out.

d. Loose wire connections or defective

d. Check connection to receptacle as-

receptacle assembly.

sembly (9, fig. 3-11) or replace.

Telescope or reticle projector will not

Dirt preventing valve from closing or

Clean or replace valve stem. Para 3-6.

hold nitrogen charge.

faulty valve.

a. Gear teeth on filter assembly housing

a. Replace filter assembly (10, fig. 3-12).

Filters not fully positioned in optical path

when viewed through eyepiece

broken.

b. Operating mechanism not adjusted

b. Reposition gear (12, fig. 3-12) to

assembly.

properly.

mesh with gear at rear of the

filter assembly housing. Operate

handle to turn filter assembly to

extreme position in both directions

and adjust stops (set-screws) (1,

and 2, fig. 3-13). Para 3-18.

Excessive parallax between target and

Optical misalinement

Use parallax adjustment screw (5, fig. 3-

reticle.

Section III. GENERAL MAINTENANCE

Item Name

Specification

FSC

2-5. General Maintenance Procedures

Grease, Aircraft and Instrument

MIL-G-23827

9150

Gear and Actuator Screw

Refer to TM 9-254.

Grease, Pneumatic Systems

MIL-G-4343

9150

Sealing Compound (Adhesive Cur-

MIL-S-11031

8003

2-6. Other Materials Required

ing)

Sealing Compound (Noncuring)

8030

The following materials are used to perform repair

functions described in this manual.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |