|

|||

|

|

|||

|

Page Title:

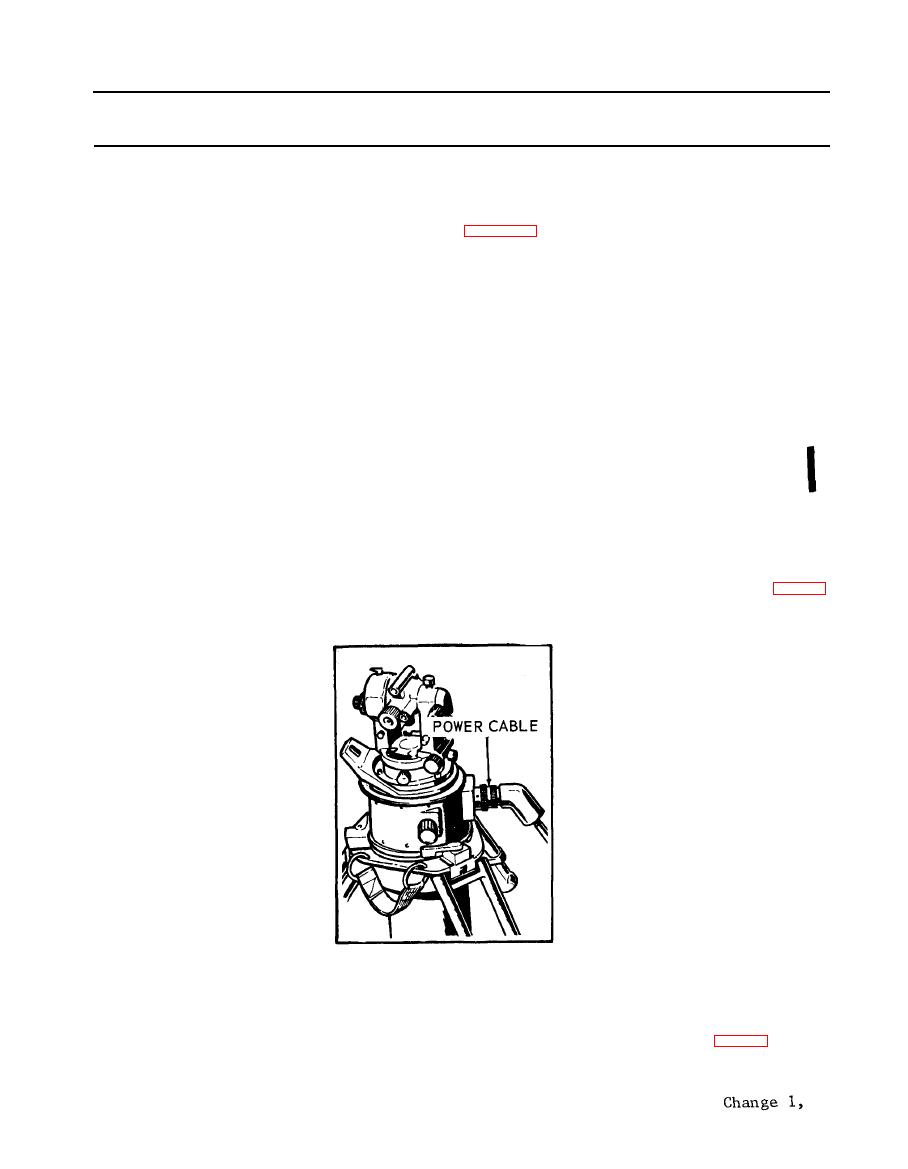

Figure 2-82. Gyroscopic reference unit power cable removal. |

|

||

| ||||||||||

|

|

TM 5-6675-250-34

Table 2-1. Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

(6). Remove the three gearbox assembly mounting screws and remove the gear box assembly.

(7). Disconnect the gearbox assembly electrical cable by rotating the connector mounting screws in

the counterclockwise direction. Alternate between the two screws every (2 to 3) turns. The

connector will be damaged if this technique is not followed.

(8). Install the anti-backlash setting tool (figure 2-81) into the index hole of the upper gear half of

the follow-up gear set, with the handle of the tool towards tbe main connector cover.

(9). Place the thumb on one end of the gear set and the index finger on the other and slide the two

gear halves together so that the ends are flush.

(10). Press the anti-backlash setting tools into tbe index hole of the lower gear half and relax the

thumb and index finger.

(11). Connect the gearbox assembly electrical cable connector to the female receptacle on the housing

connector. Rotate the cable connector mounting screws in the clockwise direction, being careful

to alternate between the two screws after (2 to 3) turns.

(12). Place the cable between the gearbox assembly mounting pads, so that it will be under the

gearbox when the gearbox is in final position.

(13). Rotate the follow-up shaft to the extreme clockwise position by turning tbe theodolite mounting

plate.

(14). Install a gearbox assembly through the access hole and place it so that the mounting screw

holes are lined up.

(15). Apply sealant primer MIL-S-22473, Grade N, form R, to the threads, and allow to air dry.

Apply a small amount of thread locking sealant, MIL-S-46163, Grade N, Type II, to the

first few threads. Install the gearbox assembly mounting screws, but do not tighten.

(16). Press the gearbox assembly against the index pins on tbe inner mounting pads and tighten the

mounting screws while maintaining the gearbox position.

(17). Remove the anti-backlash setting tool from the index bole.

(18). Install the gearbox assembly access cover and main connector housing screws. Secure each

cover with ten screws.

Step 3. Check for defective gyroscopic reference unit (GRU).

Replace existing GRU with a GRU that is operable, by disconnecting and connecting power cables (fig. 2-82).

TS 006321

If the system operates correctly with the new GRU, this indicates the original GRU was bad.

Report a bad GRU to the next higher level of maintenance.

Step 4. Check for a defective UNCAGED indicator lamp.

a. Loosen two setscrews recessed into the UNCAGED knob and remove knob from the switch shaft (fig. 2-83)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |