|

|||

|

|

|||

|

Page Title:

General Maintenance Instructions |

|

||

| ||||||||||

|

|

5-9. General Maintenance Instructions

(8) All attaching and mounting hardware for

tightness.

a. In Process Inspection. During repair, inspect

the balanced magnetic switch after removal of parts for

b. Cleaning. Use a mild solution of warm water

defects not visible when the unit is assembled. Continue

and liquid soap to clean housing and cover parts. After

the inspection during assembly to insure that parts are

cleaning rinse parts with cold water to remove any soap

properly assembled and that the unit will meet

solution and dry thoroughly. Use a soft camel's-hair

performance standards. During the repair process,

brush or vacuum cleaner with suitable attachment to

inspect the balanced magnetic switch for the following:

remove accumulated dust from components within the

alarm switch housing.

(1) Components for cleanliness.

c. Repair Precautions. Use standard maintenance

(2) Painted surfaces for deterioration or

practices and observe the following precaution: Use

scratches.

exact replacement parts. A part with the same electrical

(3) Screws for damage or corroded threads.

value or function but different physical size will cause

trouble.

(4) Nuts and screw threads to insure they are

not stripped.

5-10. Disassembly and Assembly

(5) Components for breaks, chips, cracks.

No specific procedures are required to disassemble and

(6) Moving parts for wear.

assemble the balanced magnetic switch. Component

locations and attaching parts are illustrated in figure C1.

(7) Electrical wiring for fraying or other

damage.

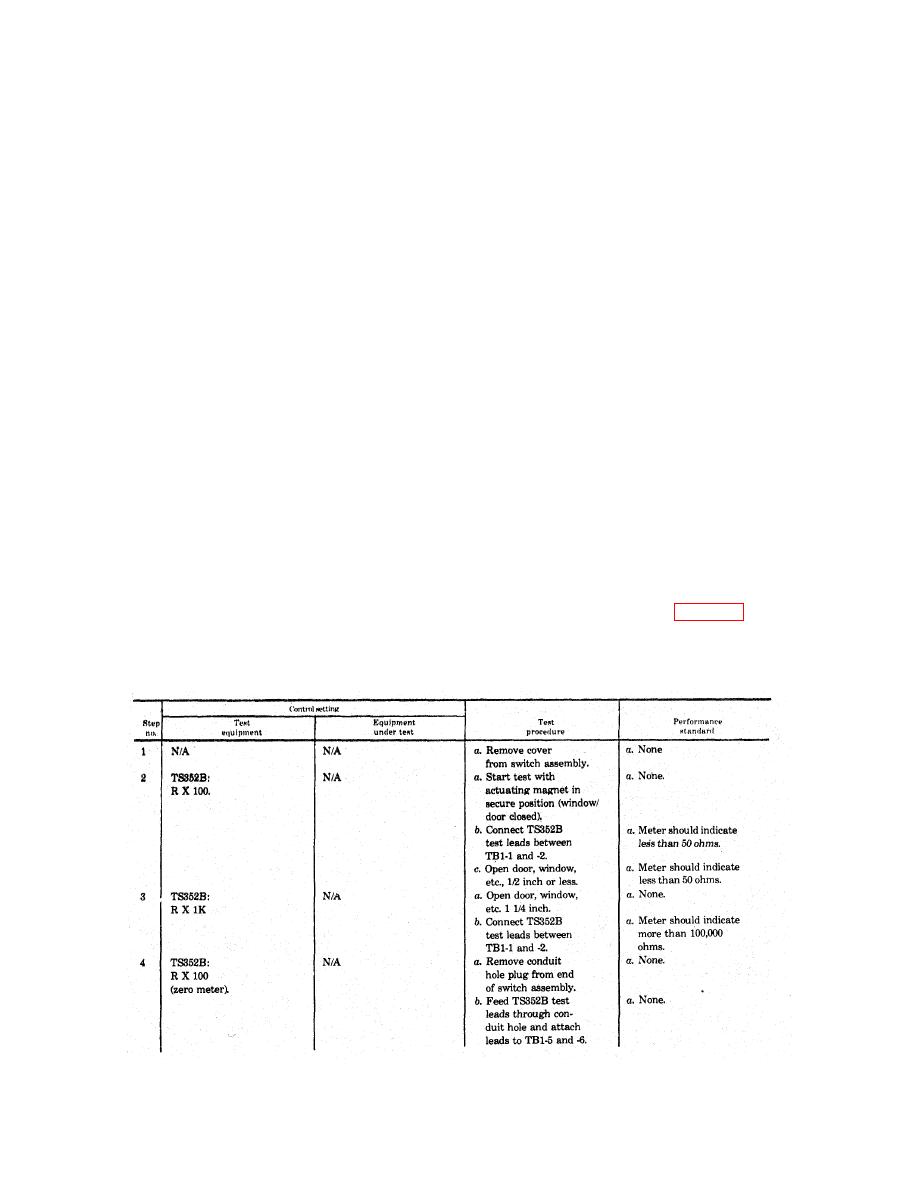

Section V. DS TESTING PROCEDURE

5-11. General

(1) VOM TS352B.

This section contains a performance standard test

(2) Test lead (2).

procedure for use in determining if the balanced

magnetic switch is operating satisfactory.

The

(3) Screwdriver, slot-end.

procedure should be used following repair and prior to

(4) Ruler, six-inch.

equipment installation.

5-12. Performance Standards

a. Test Equipment and Materials.

Table 5-1. BMS Performance Standards

5-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |