|

|||

|

|

|||

|

Page Title:

Chart 7-2. Processor/Receiver Ultrasonic Passive Signal Performance Test Procedure. |

|

||

| ||||||||||

|

|

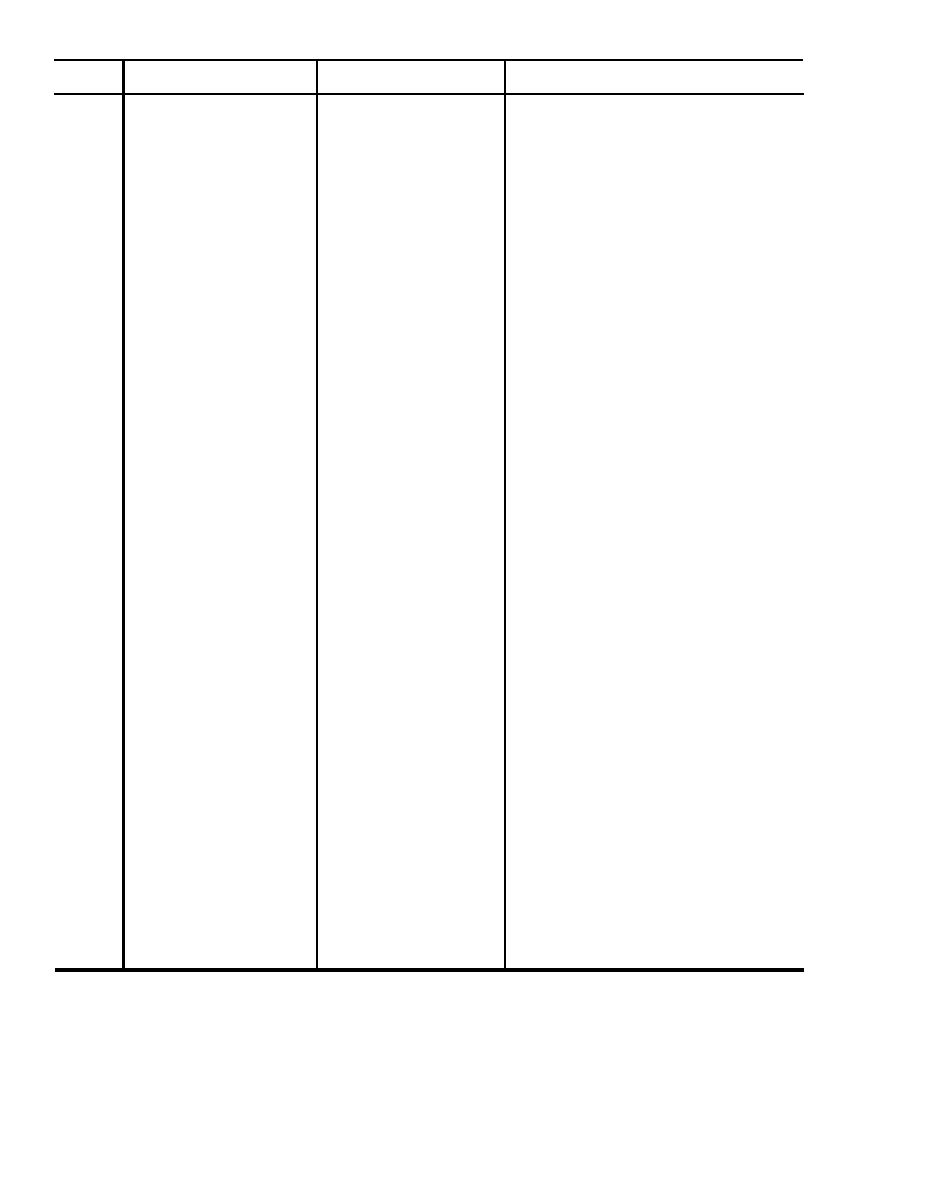

Test equipment

Test procedures

Step

Performance standard

Multimeter as continuity

3.

Connect between terminals 1

For a no alarm condition the multimeter indicates, 110

check.

and 2 of TB1.

ohms.

Audio Generator

Connect between the junction

of R2 and R3 (receiver) and

signal ground.

Observe the multimeter for an alarm cycling indication

at 22 kHz and an output

approximately every 4.5 seconds.

at .7 millivolts.

Note: The audio generator is

pulsed on and off by setting the

FREQ. RANGE MULTIPLIER

switch to an adjacent position

and back to the original setting.

b. Pulse of audio generator

Multimeter should indicate 110 ohms.

off and short circuit the

INT test point to signal

ground to discharge the

integrator capacitor C27.

c. Apply a continuous pulse

Multimeter should indicate greater than 100 K (alarm

for 5 seconds.

condition).

d. Short circuit the INT test

Multimeter should indicate greater than 100 K (alarm

point to signal ground to

condition). Observe that the alarm condition dura-

discharge integrator

tion is 0.5 to 1.5 seconds.

capacitor C27. Apply 4

pulses (50 milliseconds

duration) over a 15

second period.

Interconnect the receiver with

4.

Wideband ultrasonic

the processor using a test

signal generator.

cable of 500 feet long.

Adjust the receiver GAIN

control for a 10 db level

below maximum gain.

With the wideband ultrasonic

signal generator set for an

output level as specified in

its instruction manual for

a given distance, position

the unit directly in line

with the microphone.

Same as for corresponding performance standards for

Repeat test procedures b, c

and d above for step 3 using

step 3 above.

the wideband ultrasonic

signal generator instead of

the audio generator.

Connect as continuity measure- a . The tamper switch should open (infinity indication)

Multimeter as a continuity

5.

with no less than 1-8-inch nor more than 1-4-inch

ment between terminals 5

meter.

and 6 of TB1 on the processor

of cover displacement.

b. Pull the tamper switch plunger out and verify that

continuity is restored (near zero resistance).

c . Replace cover and verify that continuity is again

obtained (near zero resistance).

Connect as continuity measure- a. The tamper switch should open (infinity indication)

Multimeter as a continuity

6.

ment between terminals 5 and

meter.

with no less than 1/8 inch nor more than 1/4 inch

of cover displacement.

6 of TB1 on the receiver.

b. Pull the tamper switch plunger out and verify that

continuity is restored (near zero resistance).

c. Replace cover and verify that continuity is again

obtained (near zero resistance).

7-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |