|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

the other end of the cable check continuity between lead

NOTE

and conduit. Infinite indication is an open circuit.

Touchup paint Is recommended instead

d. Follow the procedure in step c above for the

of refinishing whenever practical.

remaining conductors in the cable.

(6) Check the equipment for applicable

7-7. Physical Test and Inspection

modification work orders (MWO).

a. General. This procedure is provided for use as

(7) Inspect overall unit for presence of dirt,

either the first step in troubleshooting, or use after

corrosion, moisture, and bits of wire and solder inside

repairs are completed and before the equipment is

the enclosure.

returned to the using organizations.

7-8. Symptom Analysis

b. Procedure.

Chart 7-1 lists identifiable symptoms to assist the

(1)

Inspect enclosure for evidence of

repairman in localizing potential faults.

physical damage.

NOTE

(2) Inspect terminal strips for cleanliness

and evidence of physical damage.

During performance of the symptom

(3) Check all resistors for evidence of

analysis when a pc board or a

discoloration due to overheating.

transducer Is replaced in either the

(4) Inspect all wiring and cabling for worn or

processor or the transceiver the RANGE

frayed insulation, and broken, or disconnected wires or

control must be reset and the tamper

cables.

switch circuit checked according to

(5) Inspect all metal surfaces, intended to

procedures In paragraph 2-18.

be painted, for condition of finish and legibility of panel

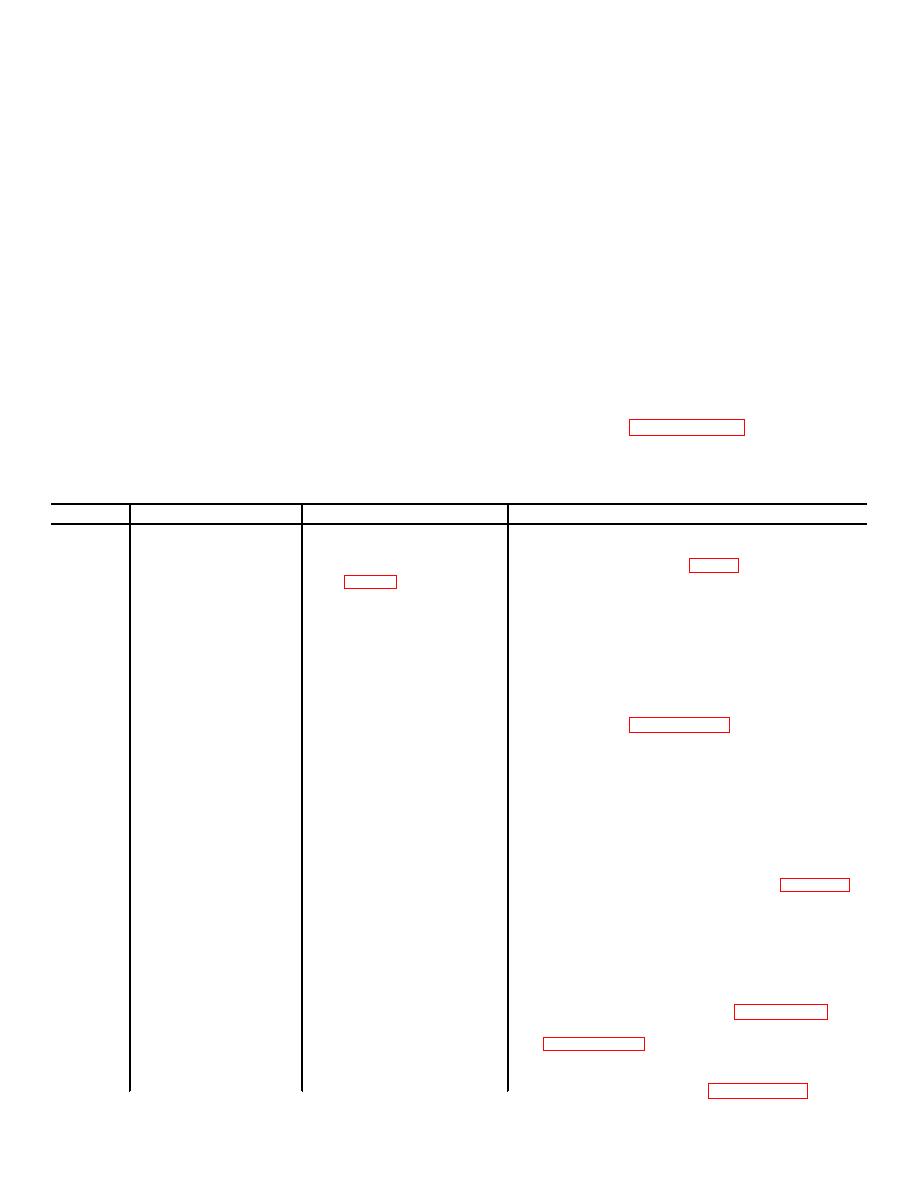

CHART 7-1. Troubleshooting Chart.

Step

Symptom

Procedure

Corrective Measures

1.

Constant alarm condition

a.

Check for 20 Vdc at

a. If voltage is below tolerance disconnect leads from

with all RANGE con-

terminals 7 and 8 of TB1

terminals 7 and 8 TB1 (fig. 1-1) and measure the

trols turned down to 1.

voltage level from the source.

b. If voltage is still below tolerance check intercon-

necting wiring.

c. If voltage is normal (202 Vdc) replace frequency

control transducer with a spare and check the in-

stallation in accordance with procedures in para-

graph 2-18.

d. If fault still exists replace processor pc board with a

spare and check the system in accordance with

procedures in paragraph 2-18.

b.

Check for 7 to 14 V rms

a. If the voltage is low or zero, disconnect the leads

at terminals 1 and 2 of

from the terminals 1 and 2 of TB2 and remeasure

TB2 in the processor.

from the voltage at these terminals

b. If the voltage is within tolerance check the inter-

connecting wires for shorts.

NOTE

All transmit transducers are connected in parallel

therefore interconnections between each unit will

have to be disconnected to isolate the cable failure.

Perform the cable checks procedure in Paragraph

7-6.

c. If interconnecting wires check correctly, temporarily

substitute a spare transmit transducer (white dot)

in each transceiver (one at a time) and recheck

voltage at terminals 1 and 2 of TB2 until the

faulty transducer has been located. When the

faulty transducer has been identified replace

transducer using procedures in paragraph 7-9.

Reset all RANGE controls using procedures in

d. If voltage is low prior to checking interconnecting

wires, replace the processor pc board with a spare

and perform procedures in paragraph 2-18.

7-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |