|

|||

|

|

|||

|

Page Title:

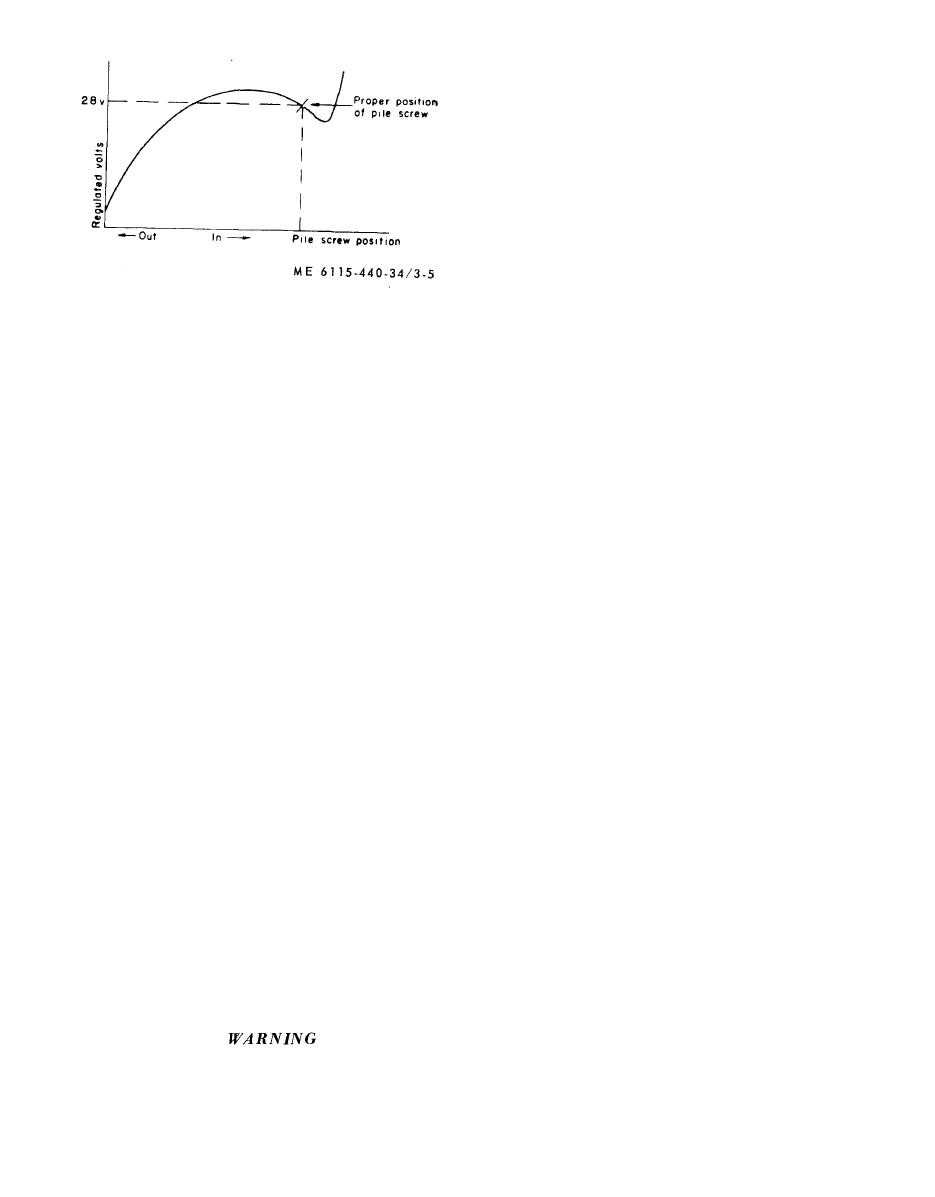

Figure 3-5. Pile screw adjustment curve. |

|

||

| ||||||||||

|

|

terminals X1 and X2, and an ohmmeter across

terminals A1 and A2.

(2) With no voltage applied, the ohmmeter

should indicate an open circuit.

(3) Slowly increase the applied voltage until

the relay actuates (continuity indicated). The relay

should actuate when the applied voltage reaches 18

volts.

(4) Slowly reduce the applied voltage until the

relay drops out (open circuit indicated). The relay

s h o u l d drop out when the applied voltage is

decreased to between 1.5 and 7 volts.

(5) Replace relay K2 if it does not pass the

test.

c. Installation. Refer to figure 3-1 and install the

Figure 3-5. Pile screw adjustment curve.

output relay.

3-3. Reverse Current Relay (K1)

3 - 5 . Terminal Board Assembly

a. Removal. Refer to figure 3-1 and remove the

a. Removal. Refer to figure 3-1 and remove the

reverse current relay.

terminal board assembly.

b. Test. U s i n g a n o h m m e t e r , c h e c k r e v e r s e

b. Inspection. Inspect terminal lugs of all

current relay (fig. 3-1) as follows:

assemblies for corrosion. cracks or other damage.

(1) Check the resistance between APP ter-

Replace if damaged.

minal and the case (Ground). The resistance should

c. lnstallation. Refer to figure 3-1 and install the

measure approximately 90 ohms.

terminal board assembly.

(2) Check the resistance between the APP and

S W terminals, The resistance should measure

3 - 6 . Load Stud Assembly

approximately 330 ohms.

a.

Removal. Refer to figure 3-1 and remove the

( 3 ) Check the resistance between the SW

load

stud assembly.

terminal and the case (ground). The resistance

b.

Installation. Refer to figure 3-1 and install the

should measure approximately 220 ohms.

load

stud assembly.

(4) Check the resistance between the BAT and

3 - 7 . Wiring Harness

IND terminals. The resistance should measure

a. Removal. Refer to figures 1-1 and 1-2 for

approximately 6 ohms.

r e m o v i n g wiring harness. Remove plastic clips

(5) Replace reverse current relay K1 if it does

where necessary when removing the wiring harness.

not pass the tests.

b. Replacement. To replace a lead, disconnect it

b. Installation. Refer to figure 3-1 and install the

at each end and install a new lead of the same size

reverse current relay.

and number. Solder or secure as applicable all

3 - 4 . Output relay (K-2)

t e r m i n a l connections to insure good electrical

a. Removal. Refer to figure 3-1 and remove the

contact. Reinstall the plastic clips after replacing

output relay.

wiring harness.

b. Test.

(1) Connect a variable 28-volt D. C. supply to

Section II. FUEL SYSTEMS

3-8. General.

for a minimum of eight (8) hours.

Remove fuel cap and open the

The fuel system maintenance consists of the fuel

discharge and return lines during

tank governor control and the governor.

welding process. Failure to observe

3 - 9 . Fuel Tank

this warning may result in serious

a. Removal. Remove the fuel tank (TM 5-6115-

injury or death.

440-20).

c. Installation. Install the fuel tank (TM 5-6115-

b. Repair. Repair the fuel tank by welding or

440-20).

brazing.

3 - 1 0 . Governor Control Assembly

a. Removal.

Before attempting to weld or braze

(1) Remove the intake manifold (TM 5-6115-

the fuel tank, steam clean the tank

440-20).

3-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |