|

|||

|

|

|||

|

Page Title:

Table 6-2. Interior Bay Superstructure Materials |

|

||

| ||||||||||

|

|

TM 5-5420-205-14

(Short End Section) Cont'd

Curb crank arms

Steel-ASTM A237, CL.B

Yes

AWS-ASTM

E7000 Series

Male and female end connectors

Steel-ASTM-A441

Yes

AWS-ASTM

E7000 Series

Rotation spline assembly

Steel-ASTM A441

Yes

AWS-ASTM

E7000 Series

c. Structural bolt replacement should be made with the

b. The aluminum structural riveting used on both

same size and grade of bolts as are used in the original

sections of the end-bay superstructure is of 7277-T4

fabrication. That is, bolt heads with three radial markings

aluminum alloy. These are large 3/4-inch diameter rivets

are Grade 5, and those with six radial markings are of

which are hot-driven. Field replacement of these rivets by

Grade 8 high-strength alloy steel.

repair rivets is, therefore, not recommended. Rivets which

have failed should be replaced by Grade 8, cadmium

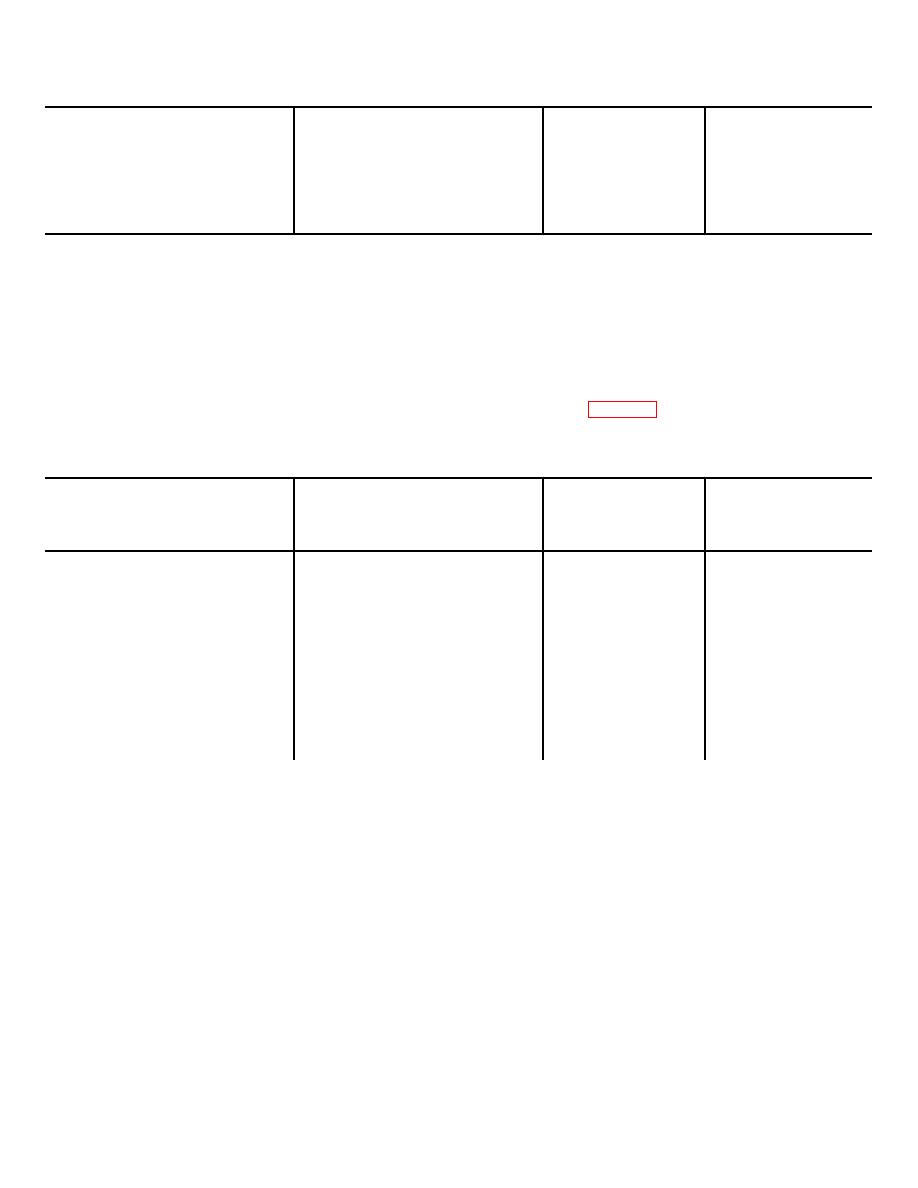

6-9. Interior

Bay

Superstructure

Structural

plated steel bolts, This grade and size of bolts should be

Description

torqued to about 275 foot-pounds to assure structural

The interior bay superstructure is fabricated from the

integrity.

materials listed in Table 6-2 below:

Table 6-2. Interior Bay Superstructure Materials

Welding

Recommended

Item description

Material and alloy

repair

weld filler

recommended

material

Girders

Steel-ASTM A441

Yes

AWS or ASTM

E7000 Series

Male and female end connectors

Steel-ASTM A441

Yes

AWS or ASTM

E7000 Series

Curbs

Steel A441

Yes

AWS or ASTM

E7000 Series

Curb support strut arms

Steel (Ends-ASTM-A441)

Yes

AWS or ASTM

E7000 Series

Curb crank arms

Yes

AWS or ASTM

E7000 Series

Rotation spline assembly

Yes

AWS or ASTM

E7000 Series

welds are highly stressed during MAB bridging and ferrying

6-10. Steel Repair of Superstructures by Welding

operations.

The structural steel used in the superstructure is high-

6-11. Aluminum Repair of Superstructures by Welding

strength low alloy structural steel with a tensile strength of

70,000 psi. Covered low alloy steel arc-welding electrodes

The only aluminum areas of the superstructures, for which

recommended for satisfactory weld repairs are identified as

repairs by welding are recommended, are in the nose

AWS or ASTM E7000 series. These electrodes are

structure of the tapered section of the end-bay. Refer to

identified in the military number series as "MIL-7000".

the tabulation under "End-Bay Superstructure Structural

These electrodes are manufactured with various covering

Description" for the Alloy identifications and recommended

materials for varying welding positions, and for AC and DC

weld filler materials. Good welding techniques, if utilized in

straight and reverse polarities. To protect against severe

this area, can produce structural repair equivalence if the

weakening of the weld due to hydrogen effects, it is

weld size, penetration, fusion, and absence of porosity are

necessary to assure that the electrode coverings have not

controlled.

absorbed excess moisture during their storage. Consult

6-12. Refinishing and Repainting

the applicable procedures for the specified welding

a. The MAB transporter superstructure

equipment and material being used. The repair weld

equipment are painted in accordance with Military

soundness should be verified as the

Specification MIL-T-704., Type B, which uses

6-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |